Hitachi Rail has become the first rolling stock manufacturer that can track the environmental and social impacts of its products throughout their life cycle.

The company has pioneered a Social Product Declaration (SPD) certification for its Masaccio hybrid trains. This will measure their impact throughout their life cycle, from manufacturing and supply chain to end-of-life management and recycling.

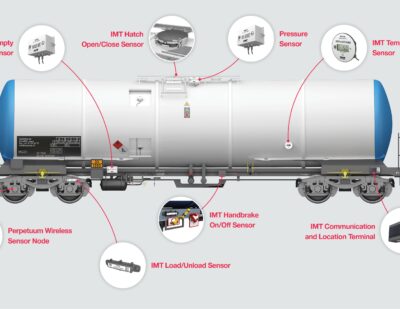

The new system was developed in partnership with EDP International. It records all work completed by suppliers across the entire value chain of the product and evaluates their social performance and ethical working practices. This includes employee safety, fair salaries, gender equality, labour laws and rule of law.

The evaluation process spans the entire 30 to 40-year life cycle of a train from design, sourcing of materials and manufacturing to decommissioning and recycling.

“We are proud to launch this world first certification for trains, enabling us to track their social impact from manufacturing to decommissioning and recycling decades later. This system enables us to assess whether our supply chain follows practices including employee safety, fair salaries and gender equality, giving confidence to our customers and their passengers in the social as well as environmental credentials of our products.

“By achieving certification for our projects, we are striving to contribute to a more sustainable and socially responsible industry - and hope other companies follow suit.”

The Social Product Declaration was designed following testing on Hitachi’s new Masaccio hybrid fleet, which is being rolled out across Italy. Hitachi Rail will now use an automated platform to manage the information gathering and certification for future fleets, as it has over 20,000 suppliers in its supply chain.

This new system complements Hitachi’s longstanding practice of calculating the environmental impact of its trains, including the energy they consume, the emissions they produce and whether materials can be recycled at the end of their life.

This has aided HItachi in increasing sustainability standards by optimising efficiency, reducing emissions to zero and achieving 95% or higher recyclability for its modern electric trains. It also enabled the company to achieve the PAS 2080 carbon reduction standard for the design, manufacture and operation of the UK’s HS2 fleet.