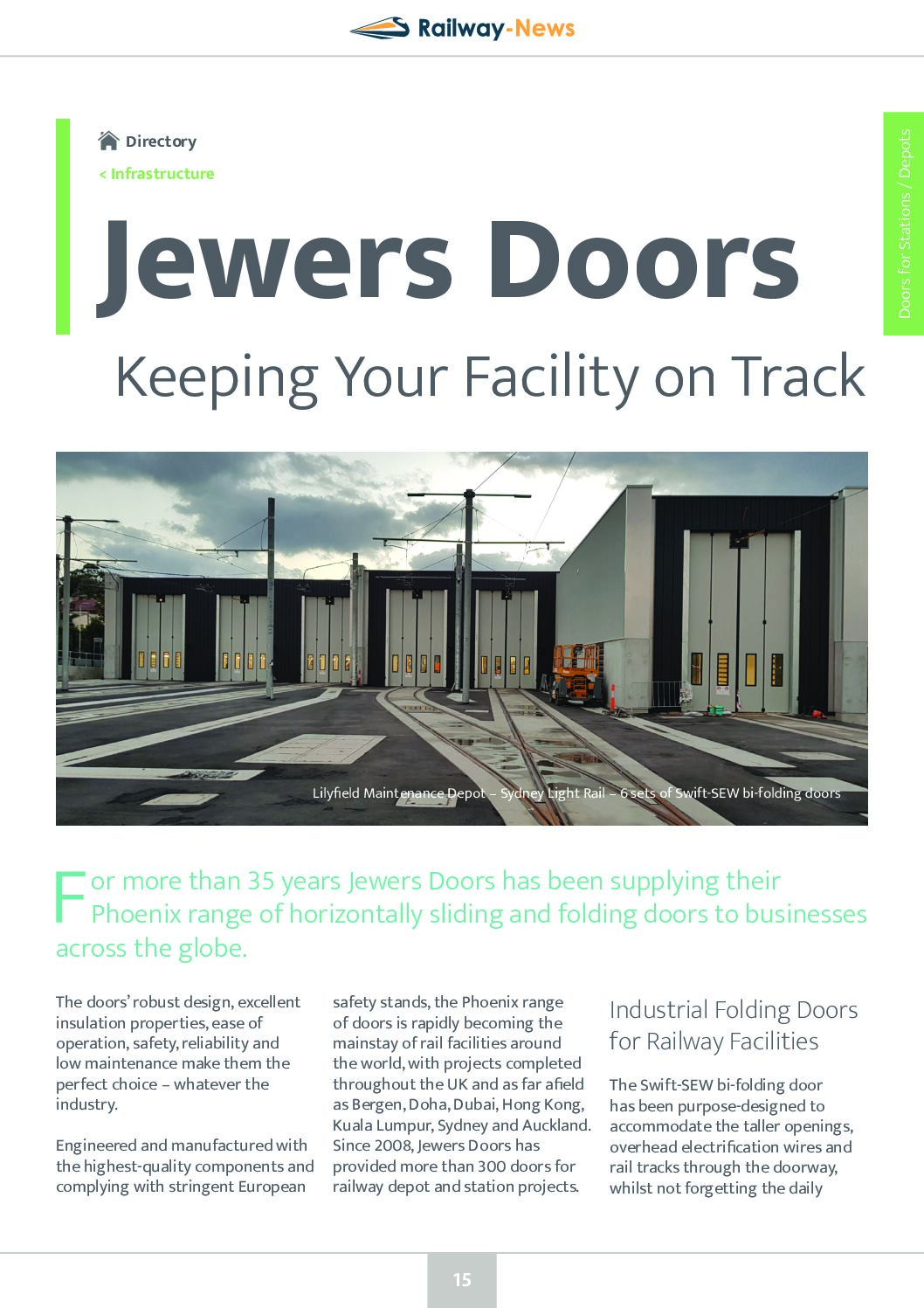

Rail & Tram Depot Doors

Industrial Doors for Train and Tram Maintenance Depots

Engineered and manufactured with the highest quality components and complying with stringent European safety standards, the phoenix range of doors is rapidly becoming the mainstay of rail facilities around the world, with projects completed throughout the UK and as far afield as Bergen, Doha, Dubai, Hong Kong, Kuala Lumpur, Sydney and Auckland.

Industrial Folding Doors for Railway Facilities

The Swift-SEW bi-folding door has been purpose designed to accommodate the taller openings, overhead electrification wires and rail tracks through the doorway, whilst not forgetting the daily operational demands and unrivalled safety requirements of modern rail maintenance depots.

Purpose-Designed Drive Systems for Bi-Folding Rail & Tram Depot Doors

Based on the original Swift door, the Swift-SEW incorporates studier hardware and a powerful central drive unit working in tandem with a programmable smart relay control board to create an extremely smooth, safe and future-proof door system that will last as long as the building.

The door can be integrated with building management systems (BMS), depot protection systems (DPS), heating, ventilation or air conditioning (HVAC), and Train Wash plant to create ultimate control. A visual display on the door control panel provides real-time status or error reporting to the user and back to Jewers’ HQ for instant fault diagnosis.

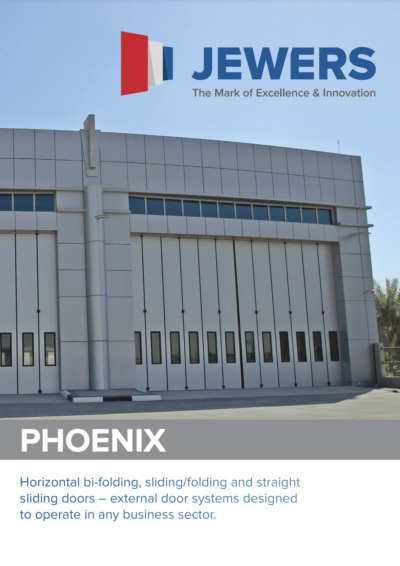

Versatile Multi-Leaf Sliding Folding Doors

The Swift-SEW door will accommodate openings up to 5m wide. For wider openings, the Osprey is the ideal solution. Powered operation is available for doors up to 20m width while there is no limit to the width for manually operated Osprey doors, which would typically be used for across railway traversers or wider depot openings.

Jewers Doors solutions are not just about being robust and durable; the Phoenix range also combines aesthetic appeal with modern technological advancements to offer rail facilities a comprehensive package that not only gives a reliable solution, but can also complement new and existing architecture.

Swift-SEW – Key Facts

- Side-hung and without a floor track to ensure door leaves glide across rail tracks.

- Electrically operated via a smooth, powerful, fast and efficient helical-worm gear motor producing high torque.

- Effortless and instant low-level manual override handle.

- Door closes around overhead line equipment (OLE).

- Designed for openings up to 5 metres wide and up to 7 metres high (max 32.5 m2).

- Multi programmable smart relay control board provides complete flexibility of operation.

- Control board integrates with BMS (building management system) and DPS (depot protection system) to create ultimate safety.

- Automatic solenoid floor bolts provide additional security and protect against high winds.

About Jewers Doors

Established in 1983, Jewers Doors is a world-leading company dedicated to the design, manufacture and installation of specialist industrial doors operating from a state-of-the-art facility in the heart of Bedfordshire, UK. With branch offices in the United Arab Emirates, North America and Turkey, Jewers Doors supplies and installs specialist industrial doors worldwide.

Since 2008, Jewers Doors has provided more than 300 doors for railway & metro depots and station projects.