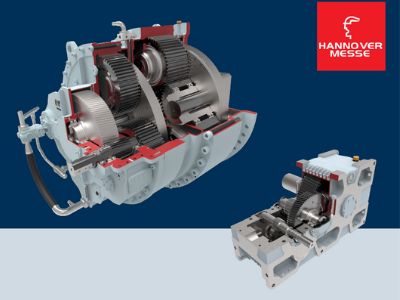

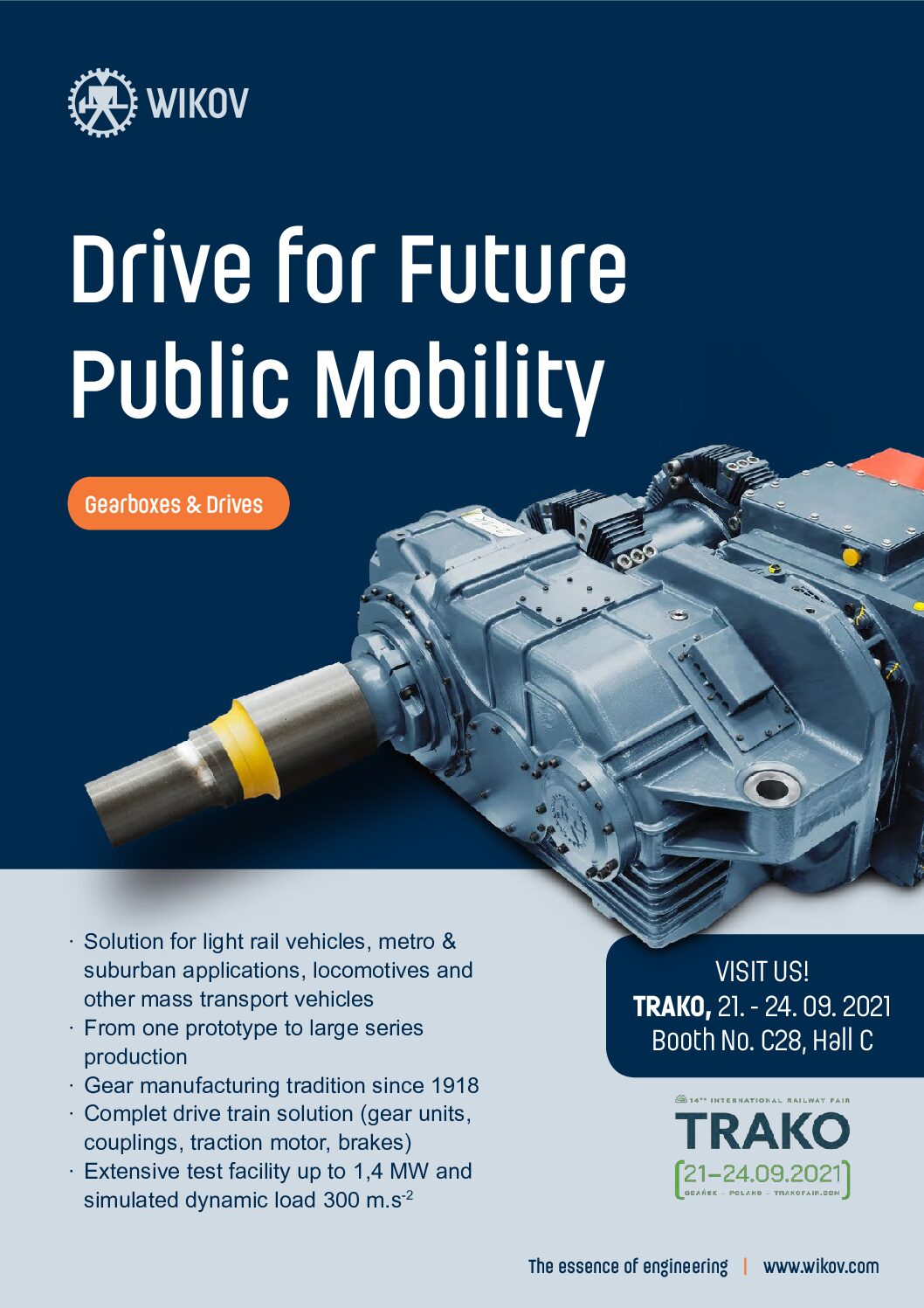

Gearboxes and Drives for Rail Vehicles

Wikov designs, manufactures, supplies and services a wide range of drive solutions for the rail vehicle industry. We offer customized solutions to meet your specific needs, including drives suitable for extremely cold conditions. We provide fast turnaround times for gear unit prototyping. Our success is based on the experience we have gained in our 137-year history, our international team of R&D specialists and our state of the art production technologies. These main pillars allow Wikov to design and engineer the best solution for you by maximizing the functional and economical parameters of your application.

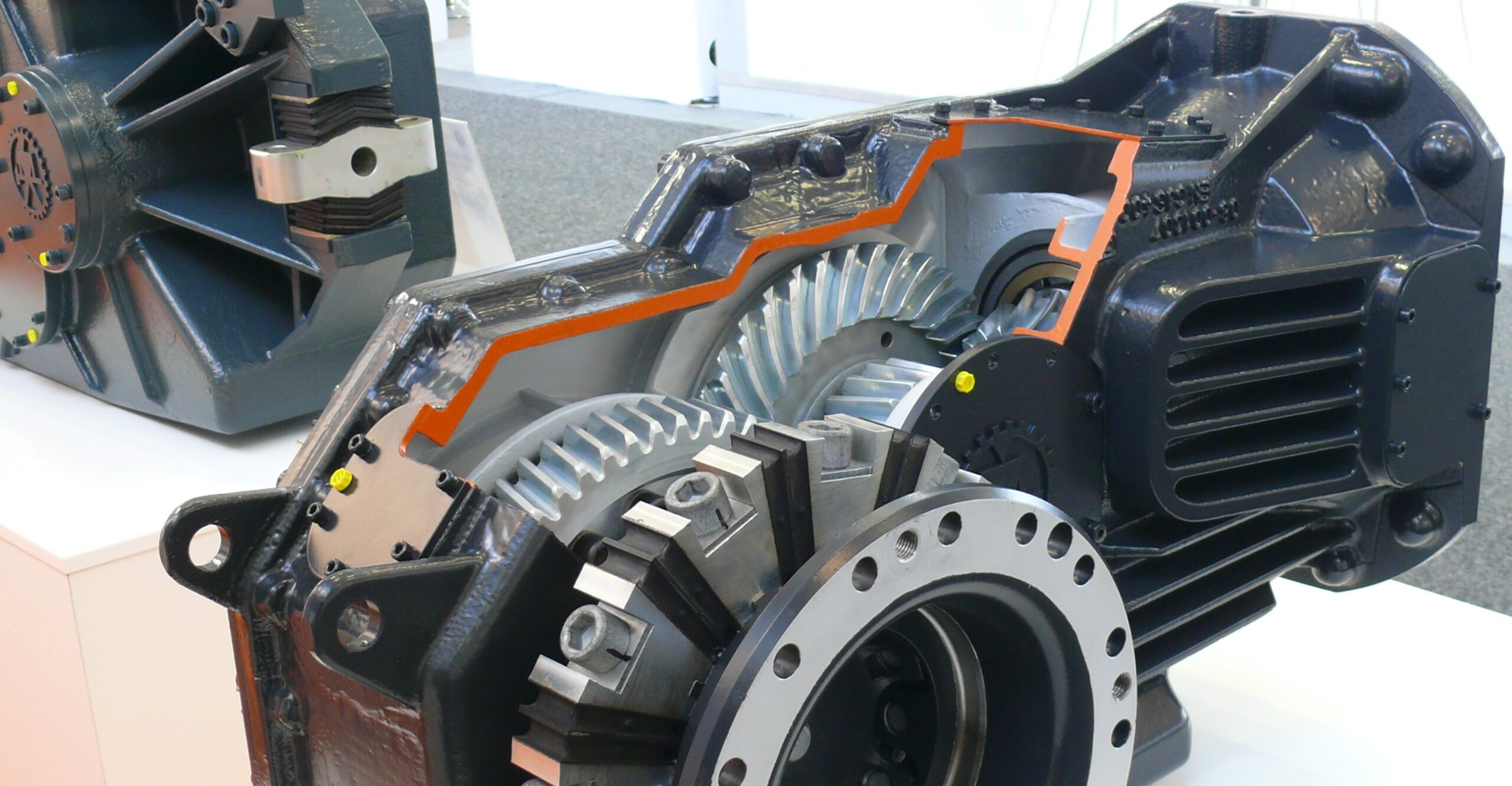

Wikov has a comprehensive series of products for railway vehicles. The German gearbox manufacturer Gmeinder also belongs to the Wikov group. Together, we have delivered more than 100,000 gearboxes and drives worldwide to the entire railway vehicles portfolio.

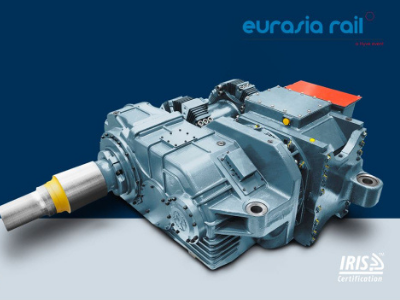

Wikov is very flexible in design and delivery and extremely fast in gear unit prototyping. Wikov can offer a few pieces of gearboxes for your vehicle prototype, and also thousands of gear units for your big EMU or metro car project. Wikov usually offers the supply of complete drive train solutions (gear units, couplings, traction motors, brakes, etc.)

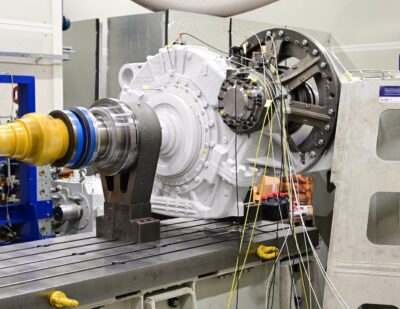

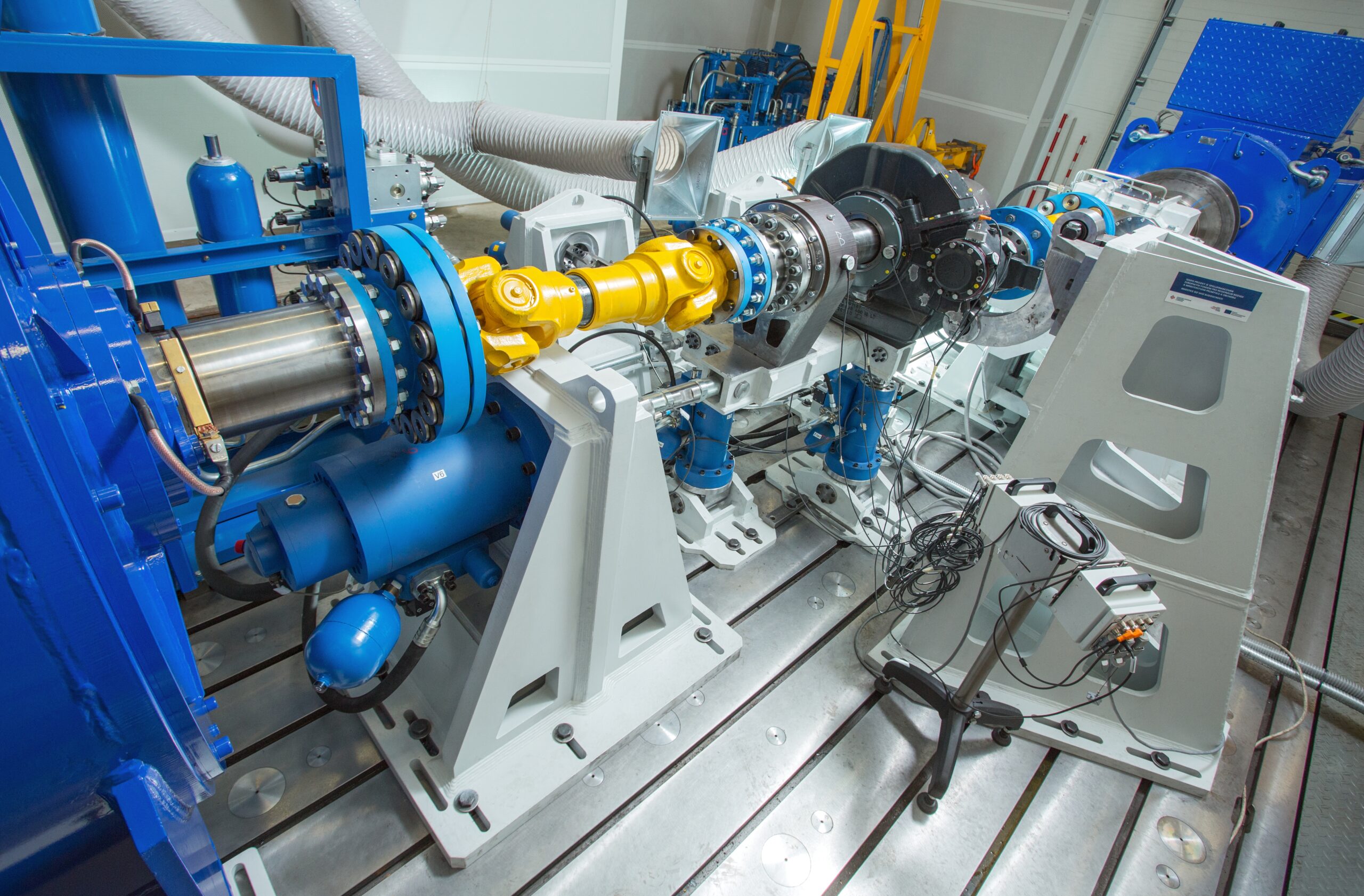

Extensive Test Facility for Gearbox R&D Activities

Wikov is absolutely self-sufficient in R&D activities. It has an extensive portfolio of test equipment. A completely unique load dynamic test rig enables simulating real conditions up to dynamic load 300 m.s-2 and power up to 1.4 MW.

Wikov traditionally supplies drives and gearboxes for rolling stock operating in extremely cold conditions. It has a cold climate chamber test for design verification of drive.

IRIS certification is a matter of course.

Global Sales and Service Network

Worldwide presence is the key to success. The Wikov group supplies gearboxes and drives all over the world and uses its extensive global sales and service network. It is thus present on all continents and in key territories.

Wikov also has years of experience with local content requirements, with current ongoing projects in South Korea and Russia, for example. Wikov is ready to open an assembly shop anywhere in the world within a very short space of time if a specific project requires it.