Laser Precision Solutions (LPS): Rail Cleaning Technology

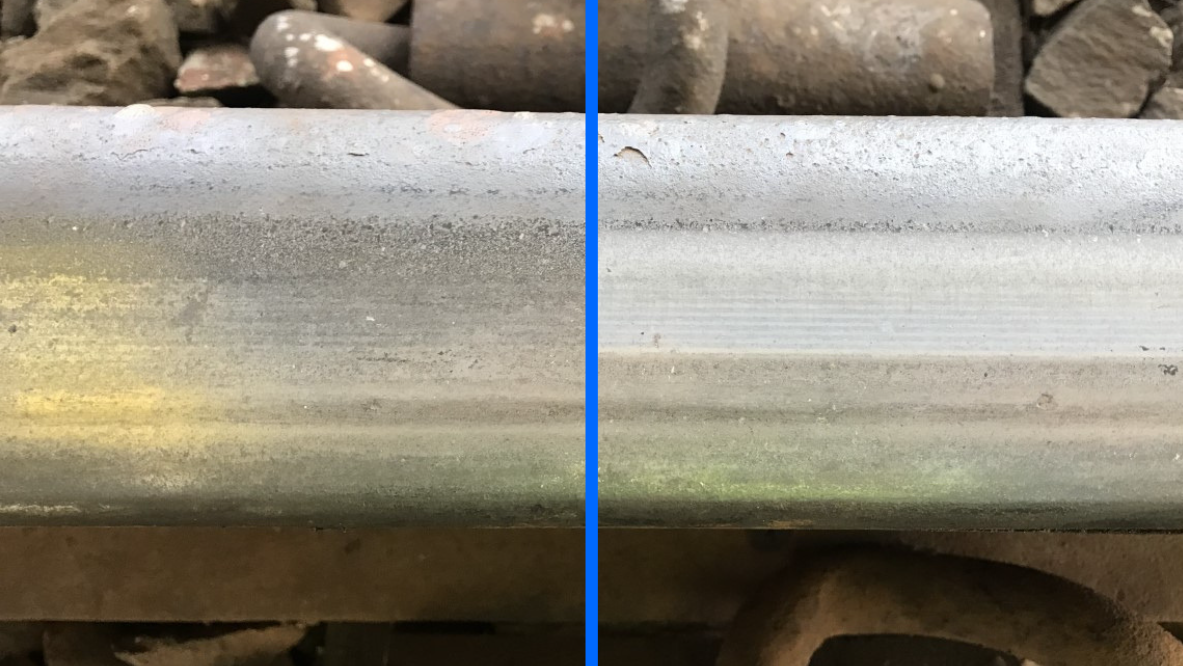

LPS has gained recognition for its advanced laser technology, particularly in the context of rail maintenance and safety. The company’s expertise lies in the design and manufacturing of high-intensity lasers specifically tailored for the removal of contaminants from railway tracks. By utilizing laser technology LPS aims to enhance rail adhesion and mitigate the adverse effects caused by crushed leaves and other debris.

LaserTrain

LaserTrain is an innovative rail cleaning solution designed to enhance safety, efficiency, and reliability in railway operations. A single pass-over can reduce rail slip risks for up to 24 hours, minimising wheel flat spots and blocks. The technique also works to clean rust, grease and oil. LaserTrain provides exceptional performance by covering large areas in little time, eliminating logistical hassles associated with water refill.

LaserTrain Benefits:

- Enhanced friction levels: safer braking and acceleration, improved train detectability and fewer SPAD incidents.

- Reduced flat spots from wheel blocks: minimal adhesion delays and equipment downtime.

- Improved operational efficiency: enables trains to adhere to schedules, reducing passenger delays and cancellations.

- Low energy consumption: LaserTrain utilises pure energy and requires no consumables or by-products, making it an environmentally friendly choice.

LaserTrain offers various cleaning speeds up to 60 mph and installation options to suit the unique needs of each rail network. The Freight Model benefits rail operators seeking an efficient and cost-effective rail cleaning solution. It’s Plug and Play elements ensures regulatory compliance, seamless production, transport and maintenance, and the initial investment costs are off-set by the lowest ongoing operational expenses in the market, ensuring long-term cost-effectiveness.

Freight Model Key Features:

- Standardized design can fit onto a Y25 bogey or R141 truck without modifications and is compatible with UK, EU and US loading gauges. This pre-set design guarantees fast production and test times, and ensures regulatory compliance from the outset.

- Installation is simple and can be completed in days without scaffolding or LPS staff.

- Easy maintenance with accessible components, ensuring cost savings and shorter lead times.

The LaserTrain Impact

The LaserTrain prototype was deployed in 2018 with the MTA Long Island Rail Road. Subsequent client expansions include the MTA Metro North, Staten Island Railway, Boston KEOLIS and WMTA Washington, as well as trials with Network Rail in the UK. In 2022, Metro-North Railroad implemented the first ever 60mph LaserTrain. 12,000 miles were covered without incident to infrastructure, resulting in a 40% decrease in slip- slide incidents and their lowest wheel-true cost season on record. Their achievement earned them the APTA Gold Award for Rail Safety.

Track Contamination Detector (TCD)

The TCD is an innovative system that measures shunting resistance of the wheel-rail system to detect rail contamination levels. Installed by mounting a detection loop to at least one truck/bogie of any train, this system provides real-time estimates of rail contamination, allowing rail operators to tailor cleaning operations efficiently. It features an ‘active loop’ with a high-frequency coil that detects the state of the passive loop formed by the wheelsets and the rail, providing insights into shunting performance.

TCD Key Features:

- Real-time estimation of rail contamination levels.

- Creation of heatmaps to pinpoint problematic network areas for cleaning.

- Easy installation and long-lasting durability.

- Currently at Technology Ready Level 6-7, undergoing field testing in the US.

Slippage on the line is a critical issue that impacts rail safety, maintenance costs, environmental sustainability and the customer experience. LPS combines advanced technology, precise cleaning capabilities and flexible options to provide efficient and tailored track cleaning solutions. Let LPS help you optimize your rail maintenance operations.