Custom Made Gears and Machined Parts for the Rail Industry

Mini by Name but Larger by Our Machining Capabilities!

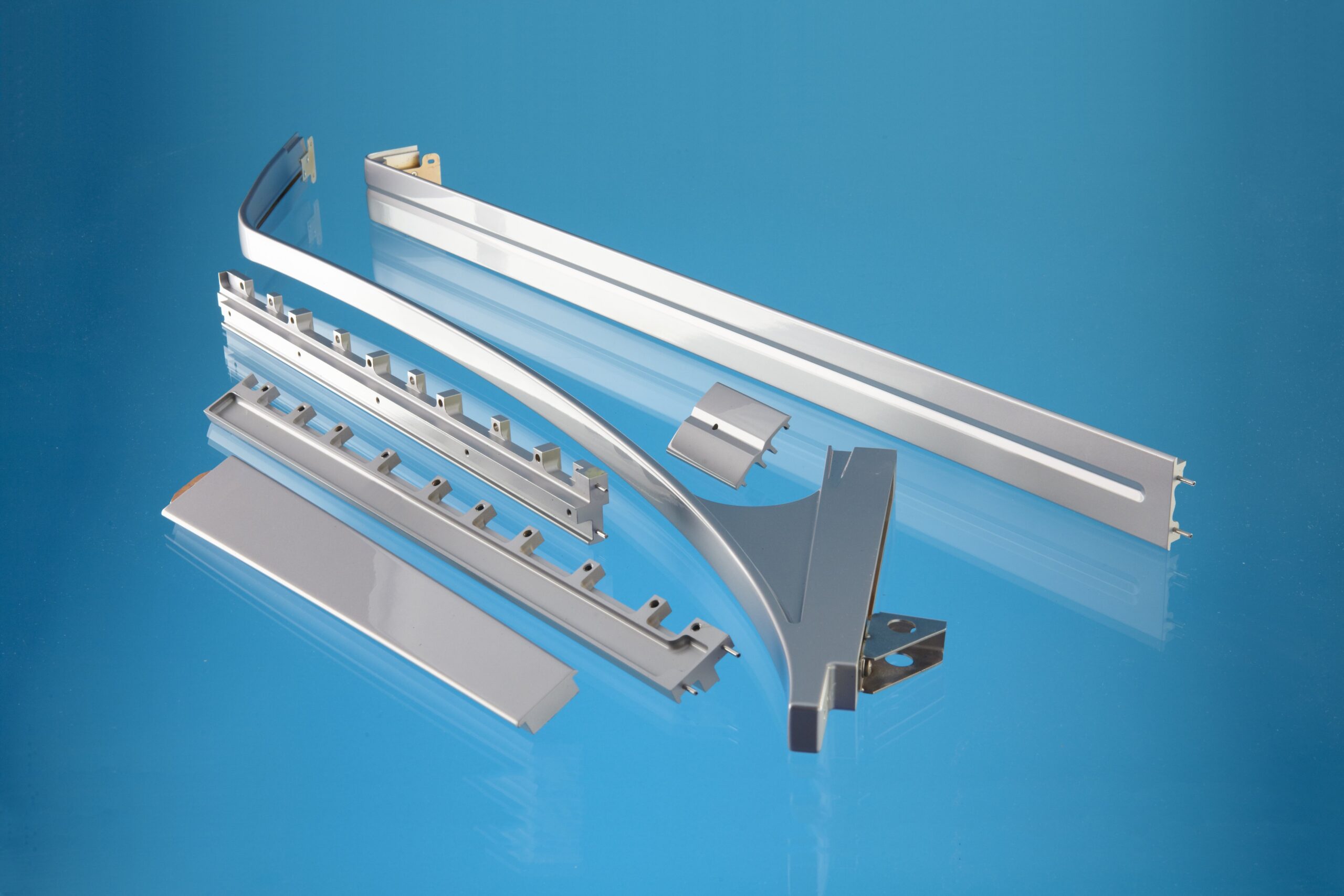

Specialist UK subcontract manufacturer of custom made Precision Machined Parts, Gears, Shafts and Gear Racks for Power Transmission applications including gear boxes, drive train systems, electric motors, vacuum pumps and lifting mechanisms used in the Rail Industry. We also have 5 axis machining capability to manufacture metal components not requiring a geared drive.

All we need from you is a drawing / 3D model file to quote for your bespoke requirements.

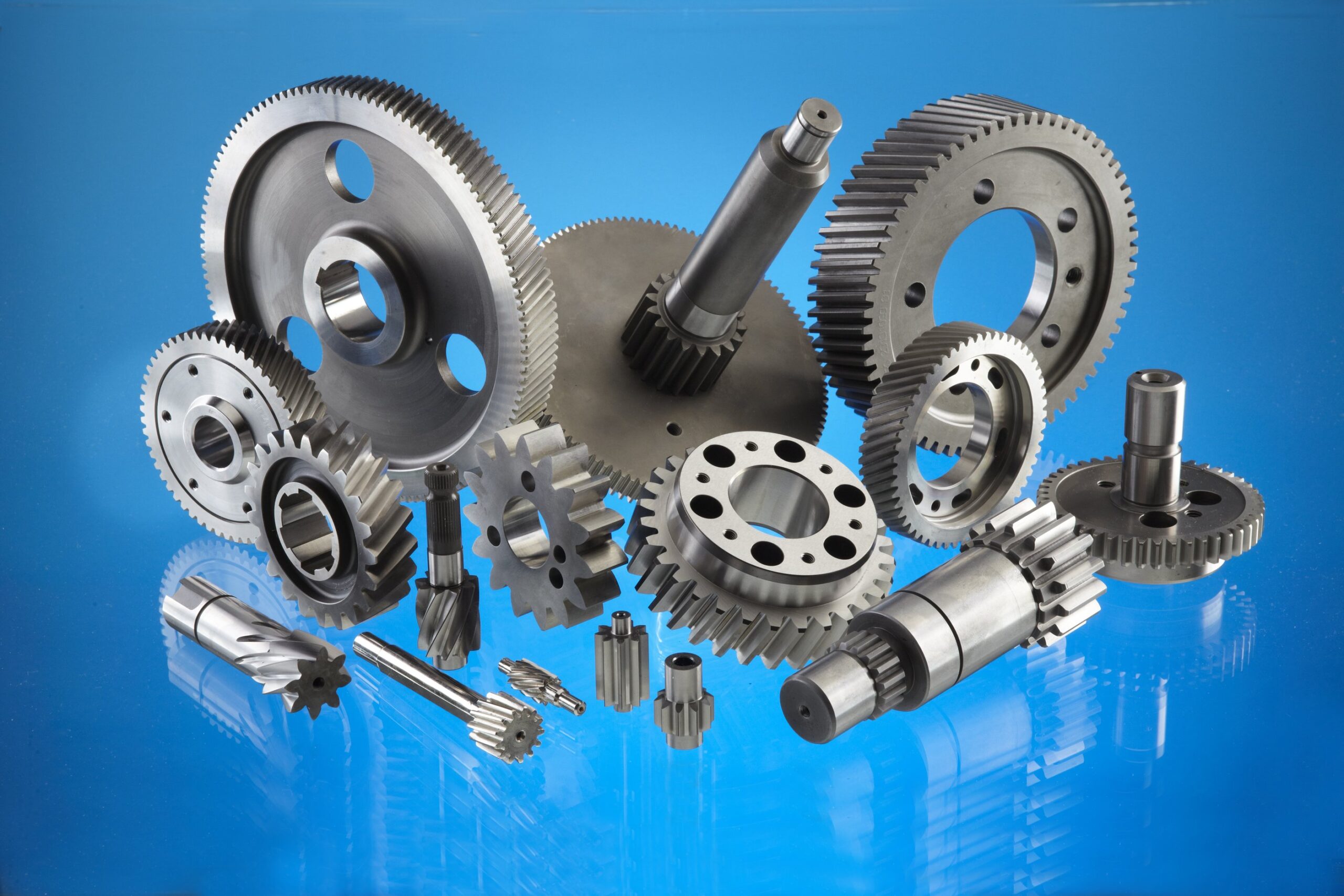

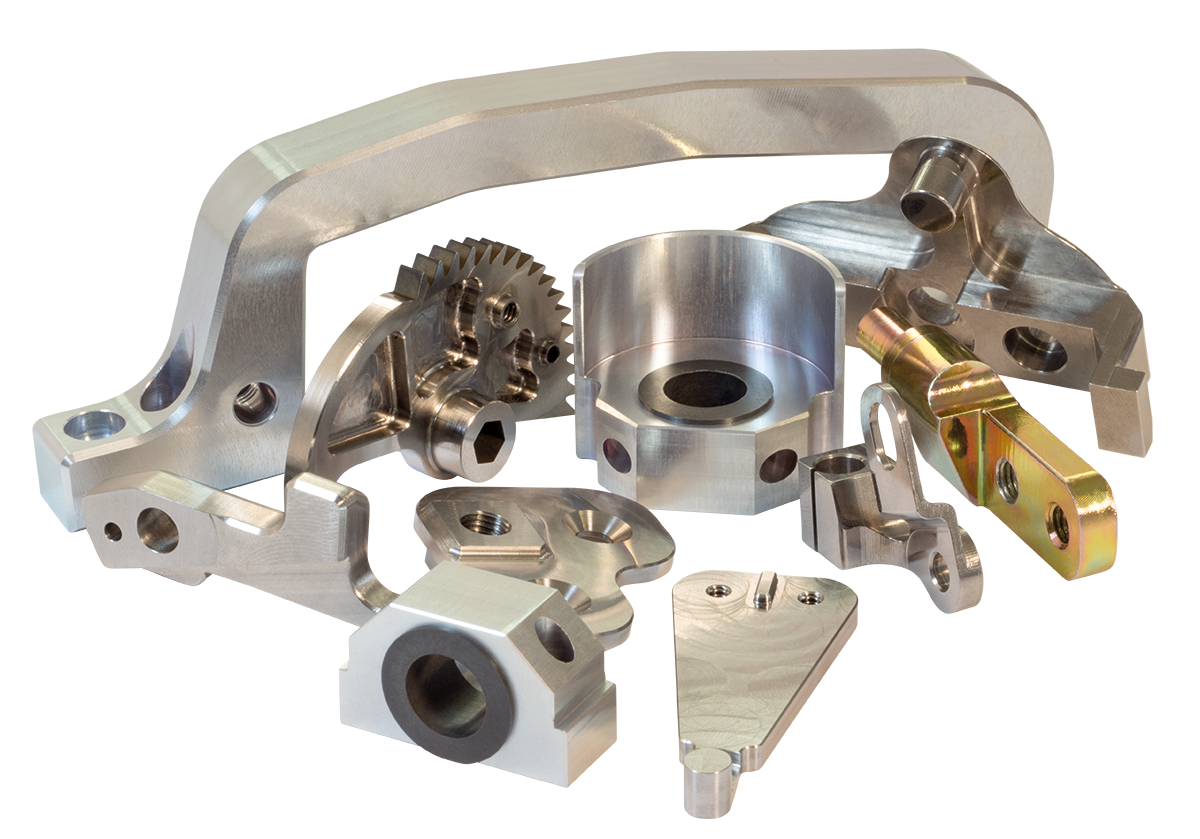

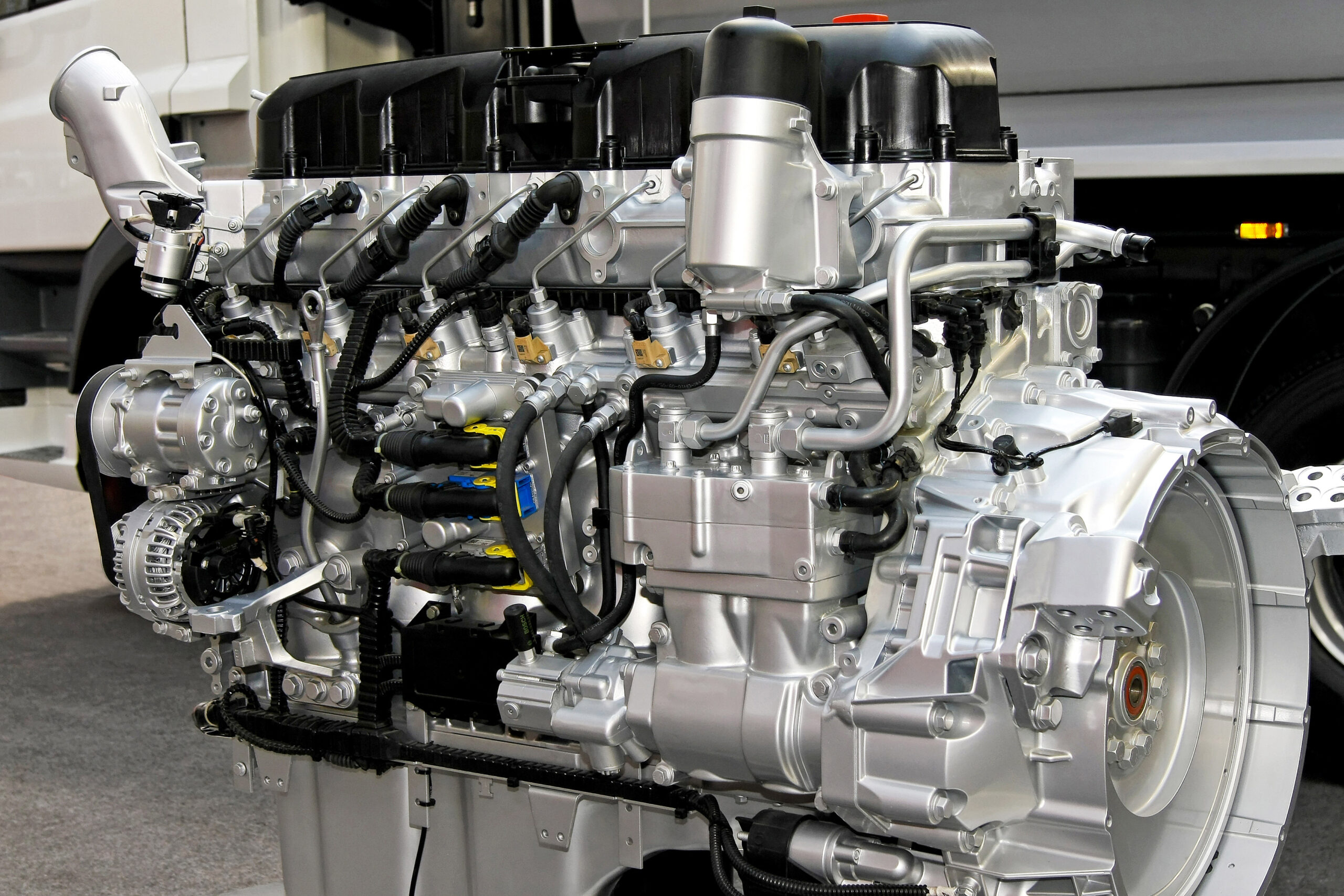

Rolling Stock Components for Diesel and Electric Engines

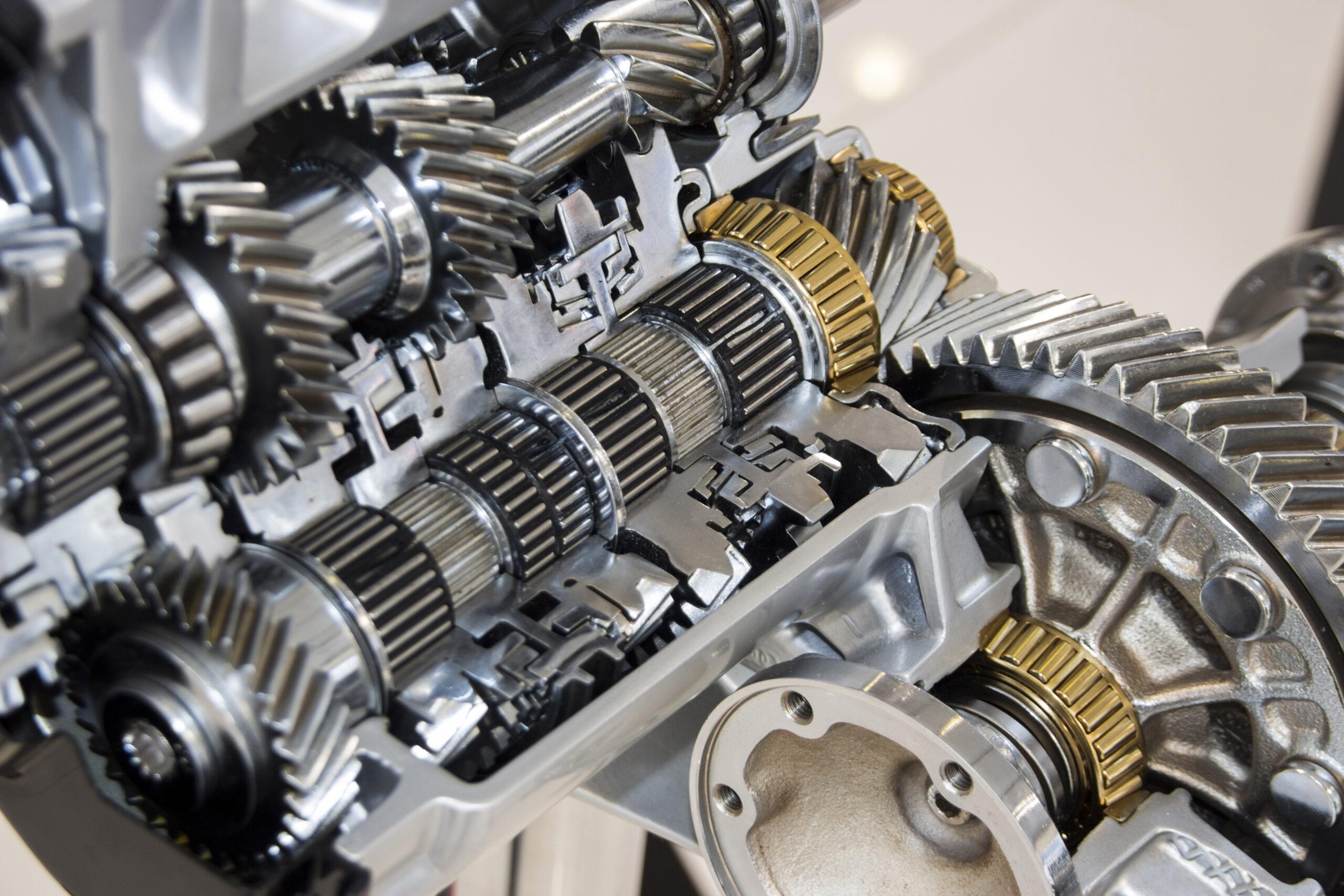

Parts for Locomotive Engines and Gearboxes

Mini Gears (Stockport) Ltd is a privately owned engineering company and has been manufacturing gears for 55 years. Our vast experience making the parts is often a massive benefit to our customers when specifying a new design. The products we can manufacture for the engines and gearboxes in locomotives are:

- Ground Gears – now up to 800mm dia.

- Spur Gears

- Helical Gears

- Flywheels

- Layshafts

- Spline Shafts

- Gear Shafts

- Timing Pulleys

- Sprockets

- Worms & Worm Wheels

The above gears can also be manufactured for other component parts of the train such as Bogies and Running Gear, Axle Boxes and Braking Systems.

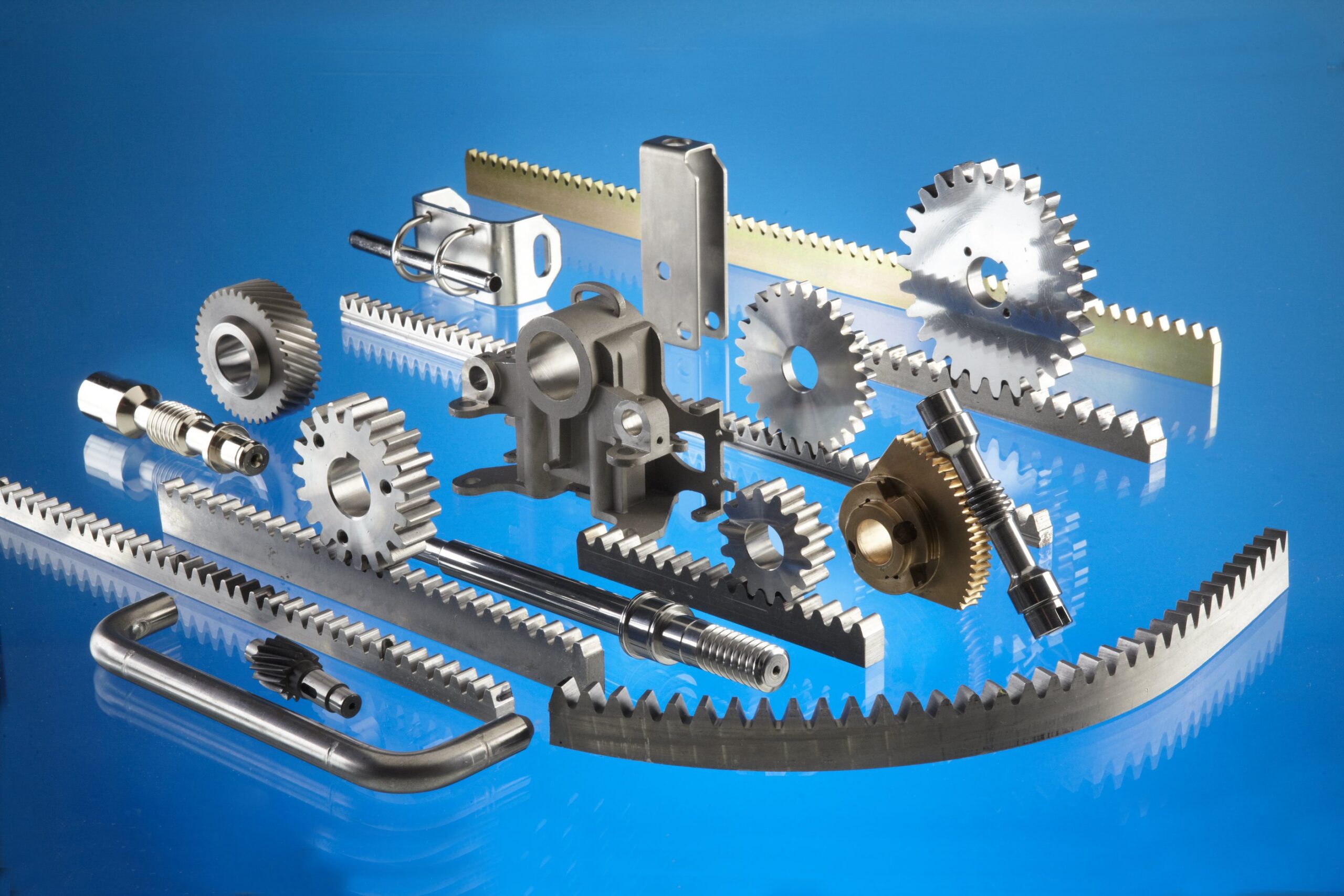

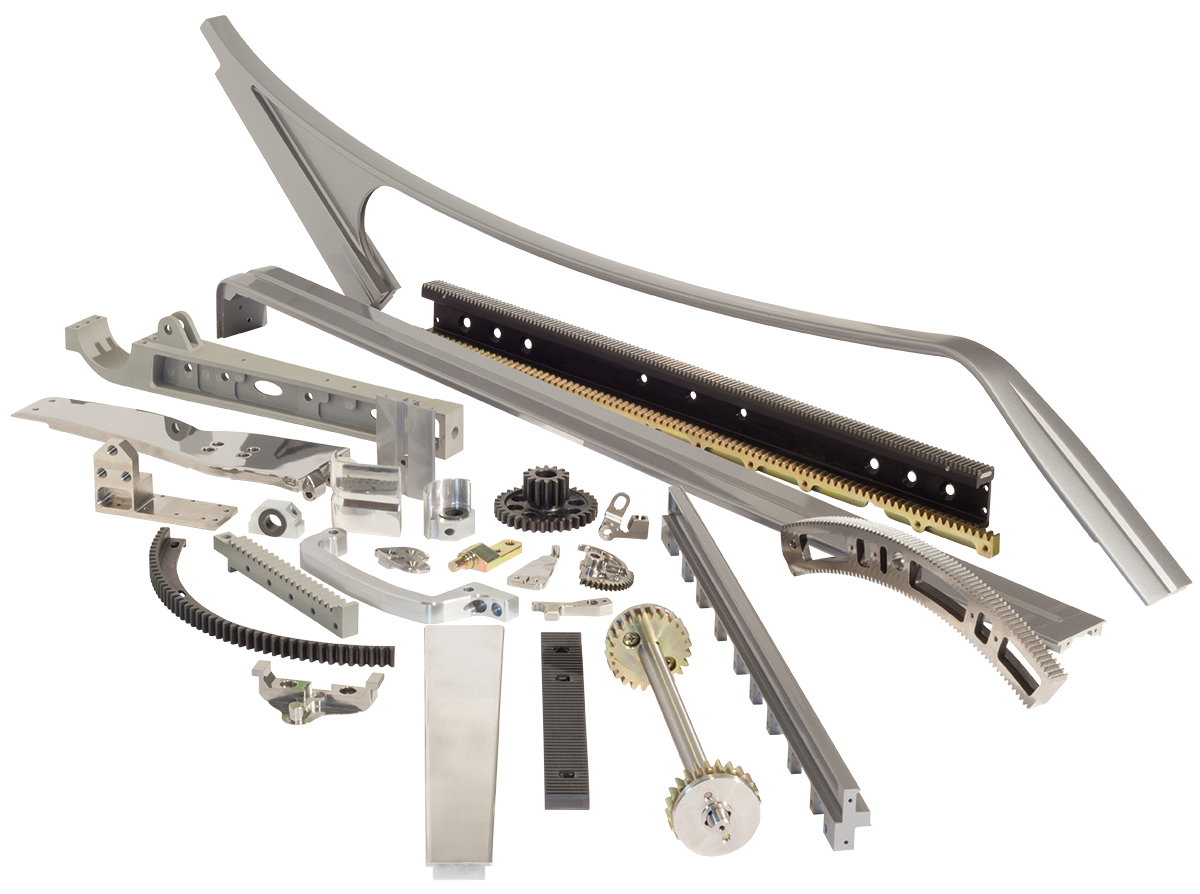

Gear Racks and Pinion Sets

Racks and Pinions for Rail Industry Applications

Mini Gears has many customers across different market sectors who require gear racks and pinion sets in their products. We have a range of machinery to cut, mill and drill gear racks together with gear cutting machines for the manufacture of the pinions. The smooth running of mechanisms using rack and pinion drive is of paramount importance and our knowledge and expertise gained in this area gives us the core competence to serve the rail industry in applications such as:

- Train Doors mechanisms

- Platform Doors mechanisms

- Lifts and Lifting Equipment

- Switchgear Units

- Valves

- Portable drilling machines

- Accessibility Equipment

- Tipper mechanisms

- Seating mechanisms

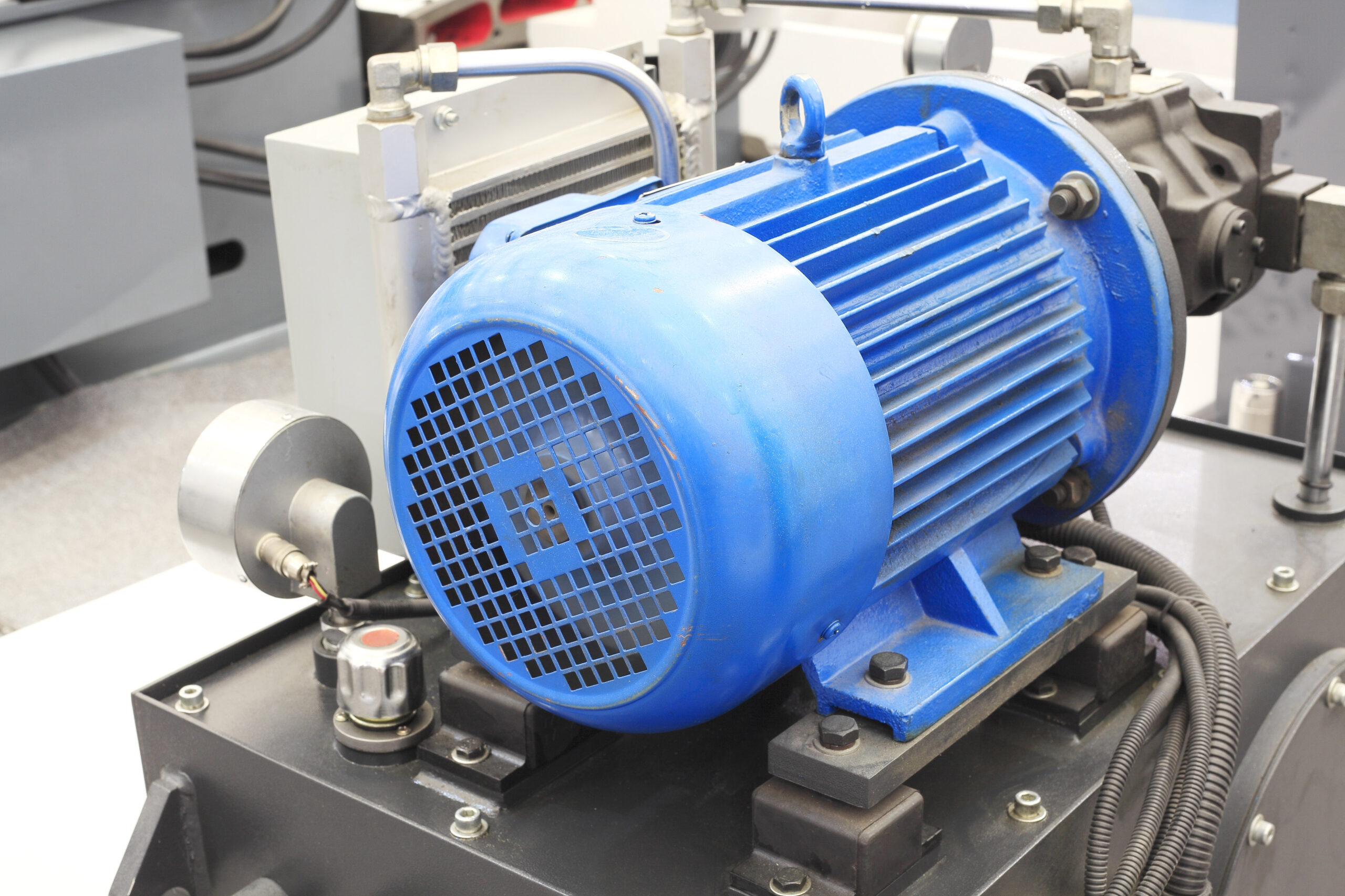

Vacuum Pumps, Valves and Electric Motors

Gears and Machined Parts for Rail Industry Pumps, Valves and Electric Motors

Mini Gears has a long history with the Pump, Valve and Electric Motors markets, manufacturing the gears and machined parts that make up these units that are used throughout the rail industry. With our innovative approach and years of experience in this field we have helped our customers with design and manufacturing costs. We have invested heavily in hi-tech heavy duty Turning and Milling machines to enable us to machine corrosion resistant alloys required for harsh environments.

Value, Quality & Service

Mini Gears holds certification to ISO 9001 & AS9100 rev D for Aviation, Space and Defence and we are committed to Value, Quality and Service.

Services we offer: CNC Gear Cutting, CNC Gear Grinding, CNC Turning, CNC Milling, 5 Axis CNC Machining, Assembly and friendly Technical Support.

Capacity

Over 100 machines at our 35,000 sq.ft. (3252 sq.mtrs) manufacturing facility in the UK. We continually invest in future capacity to compete in the markets we serve and support our customers’ product lines.

We have a large range of CNC machines including powerful multitasking twin chucked machine tools for 5 axis machining, semi-manned turning centres, high speed vertical machining centres for aluminium machining, CNC lathes, CNC gear cutting, hobbing and shaping machines, CNC gear grinding and CNC checking up to 800mm dia.

Gear Cutting Capacity and Materials

Sizes:

- Commercial Gears from 25mm – 600mm dia. – Max. pitch = 8 Mod (3DP)

- Internal Gears – Max. pitch = 6 Mod (4DP) Max. face width = 125mm (5″)

- High Precision Gears up to 800mm dia. 1 – 15 Module. Max. face width = 600mm

Materials:

- Alloy steels for hardened high precision gears

- Non- alloy steels for unhardened commercial gears

- Stainless steel

- Phosphor Bronze

- Aluminium Bronze

- Delrin (nylon) – various grades of nylon

- Peek (an organic thermoplastic polymer – fire resistant material for aerospace)

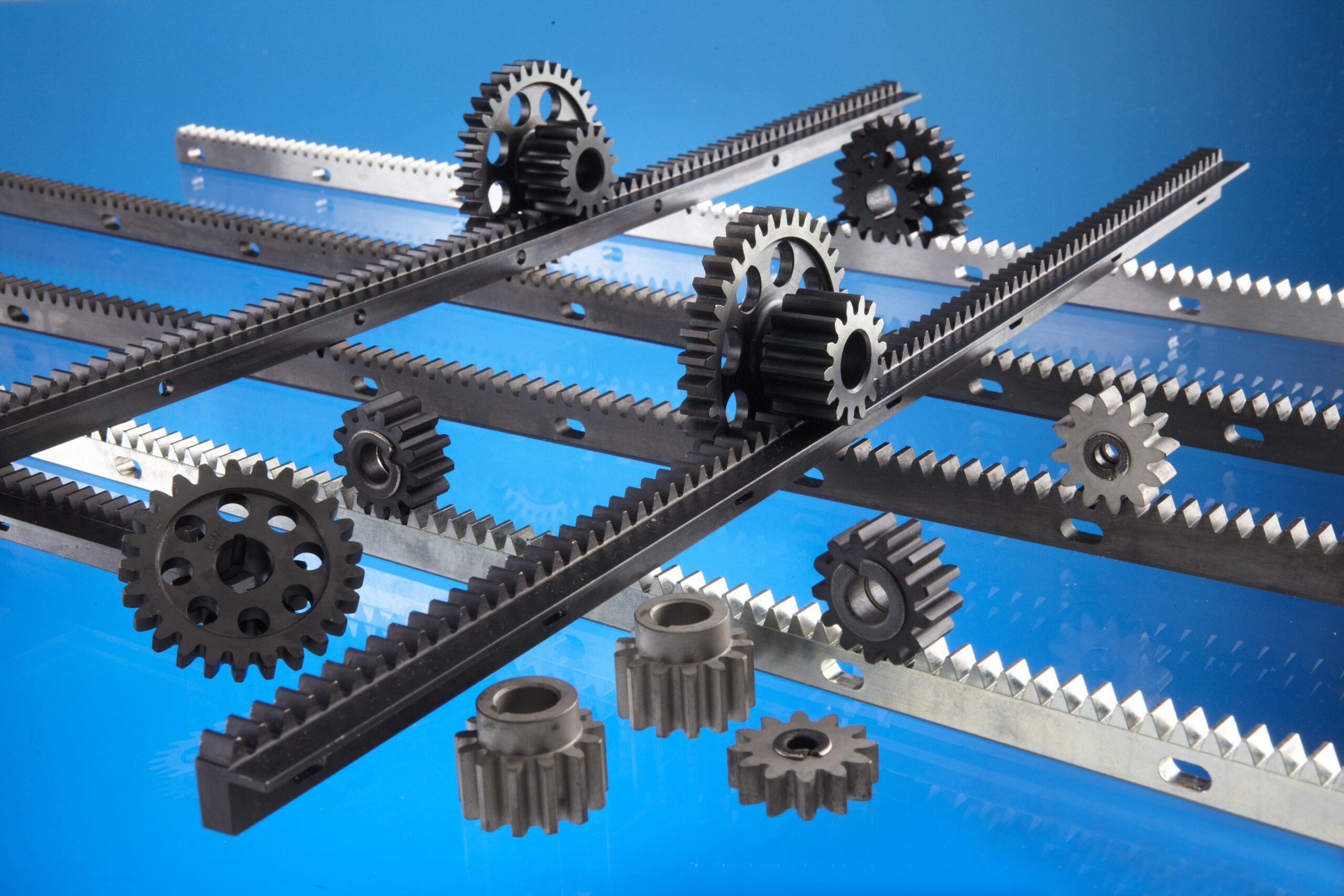

Rack Cutting Capacity and Materials

Sizes:

- Maximum length: 3 metres

- Maximum pitch: 4 Mod (6DP)

Materials:

- Steel, stainless steel & aluminium

Machined Parts Capacity and Materials

Sizes:

- Turning: Max. dia. 800mm

- Turning: Length: 1030mm

- Milling up to 3 metres long

Materials:

- Ferrous: Various grades of steel including Exotic Steels: Super Duplex, Duplex, Inconel & Stainless

- Non Ferrous: Aluminium, Brass & Bronze

Surface Treatment

Along with our machining capabilities we also look after any additional surface treatment requirements, for example heat treatment and corrosive surface treatment, as a complete package.

Why Choose Mini Gears?

With 55 years of machining and gear manufacturing knowledge, together with our commercial experience, Mini Gears (Stockport) Ltd is renowned as one of the leading specialist subcontract engineering companies in the UK and we have won many industry awards for machining excellence, innovation and supply chain partnerships. We work closely with our customers, becoming your engineering partner and helping you gain a competitive advantage with your products.

Learn more about Mini Gears at www.minigears.co.uk

We look forward to quoting for your requirements. Please send your drawings / 3D models (dxf / stp files preferred) and quantities to us today: [email protected] or call us on +44 (0) 161 432 0222 and ask to speak to our Technical Sales Team.