Highly Precise Profile Measurement for Predictive Maintenance

NEXTSENSE develops and markets optical systems for profile measurement in the automotive, railway and steel industry.

With its unique CALIPRI technology, NEXTSENSE is one of the world leader in mobile profile measurement systems for wear measurement of wheels, rails and tracks. The CALIPRI non-contact profile measurement devices are based on laser light section technology, thus ensuring highly accurate and reproducible measured data.

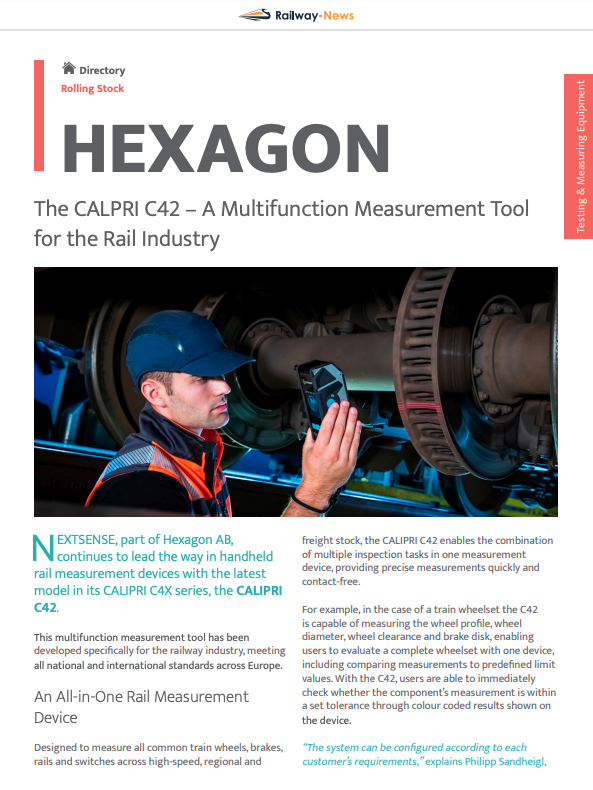

The multifunctional CALIPRI C42 enables the combination of several inspection tasks (measurement modules) in one measurement device. For example, if you combine the modules for wheel profile, brake disk, wheel diameter and wheel clearance, you have a measurement device for evaluating a complete wheelset. Due to the various export and report functions it guarantees an improvement and simplification of the whole workflow.

CALIPRI X is a fully automated on-track wheelset measurement system that delivers significant productivity gains and operational cost savings to the rail sector. It is easily installed on existing tracks and is designed for 24/7 all-season operation.

Combined with the analytical capabilities of the easy-to-use cloud storage and analysis tool CALIPRI Predictor all measurements with CALIPRI devices are securely stored, highly available, safe to access and cost effective. By predicting wear levels, the maintenance schedule can be adjusted to the condition of the vehicles. This enables predictable and safe operation of the fleet.

Customers including all big European railway companies like DB, ÖBB, SNCF, Trenitalia and numerous major railways worldwide trust the CALIPRI technology for many years. With around 80 employees, over 50 sales partners and embedded in the Service & Sales network of the parent company Hexagon AB, the high-tech company is represented all over the world. Since May 2018 NEXTSENSE is part of Hexagon AB, a leading global provider of information technologies.