Remote Condition Monitoring Solutions for Rail Assets and Infrastructure

Transmission Dynamics specialises in remote condition monitoring solutions, with an integrated suite of proprietary hardware and software, and cutting-edge machine learning and artificial intelligence technologies. The need for more efficient and reliable railway monitoring methods has become paramount for rail operators and infrastructure maintainers worldwide. Through a range of train-borne remote condition monitoring sensors, Transmission Dynamics offers advanced onboard analytics during routine train operations, providing significantly enhanced rail infrastructure and asset monitoring intelligence. These solutions improve rail reliability and service safety, increasing operational efficiencies while reducing downtime and associated costs.

Overhead Line and Pantograph Monitoring System

Transmission Dynamics train-borne PANDAS-V® camera system is an advanced, AI-enable remote condition monitoring solution designed to detect changes in overhead line conditions. Equipped with a roof-mounted camera synchronised with a pantograph-mounted wireless accelerometer, the PANDAS-V® system captures video footage of potential issues based on impacts as the train is in motion. The system produces 10-second clips of the fault and pinpoints precise locations for immediate analysis through automatic and instantaneous reporting to relevant stakeholders.

The real-time onboard processing capabilities of the PANDAS-V® system saves critical time in fault identification and allows stakeholders to implement fault remediation works appropriately and before the issue causes further damage. As well as reporting impacts and identifying issues such as broken dropper wires, misaligned neutral sections, pantograph flip, arcing and bird strikes, PANDAS-V® offers a comprehensive range of additional critical measurements related to pantograph and overhead line performance. Currently, these measurements encompass parameters such as pantograph height, wire stagger, and carriage sway. Soon, the system will incorporate features like carbon wear monitoring and contact force measurement (uplift), enhancing its diagnostic capabilities even further.

Impact and Benefits:

- Maximised operation efficiencies – through preventative rather than reactive maintenance.

- Increased safety – by reducing boots on ballast.

- Reduced delays – caused by infrastructure faults and unplanned maintenance.

- Reduced cost – by reducing downtime, identifying, and mitigating potential hazards, and streamlining maintenance processes.

Rail Asset Monitoring Systems

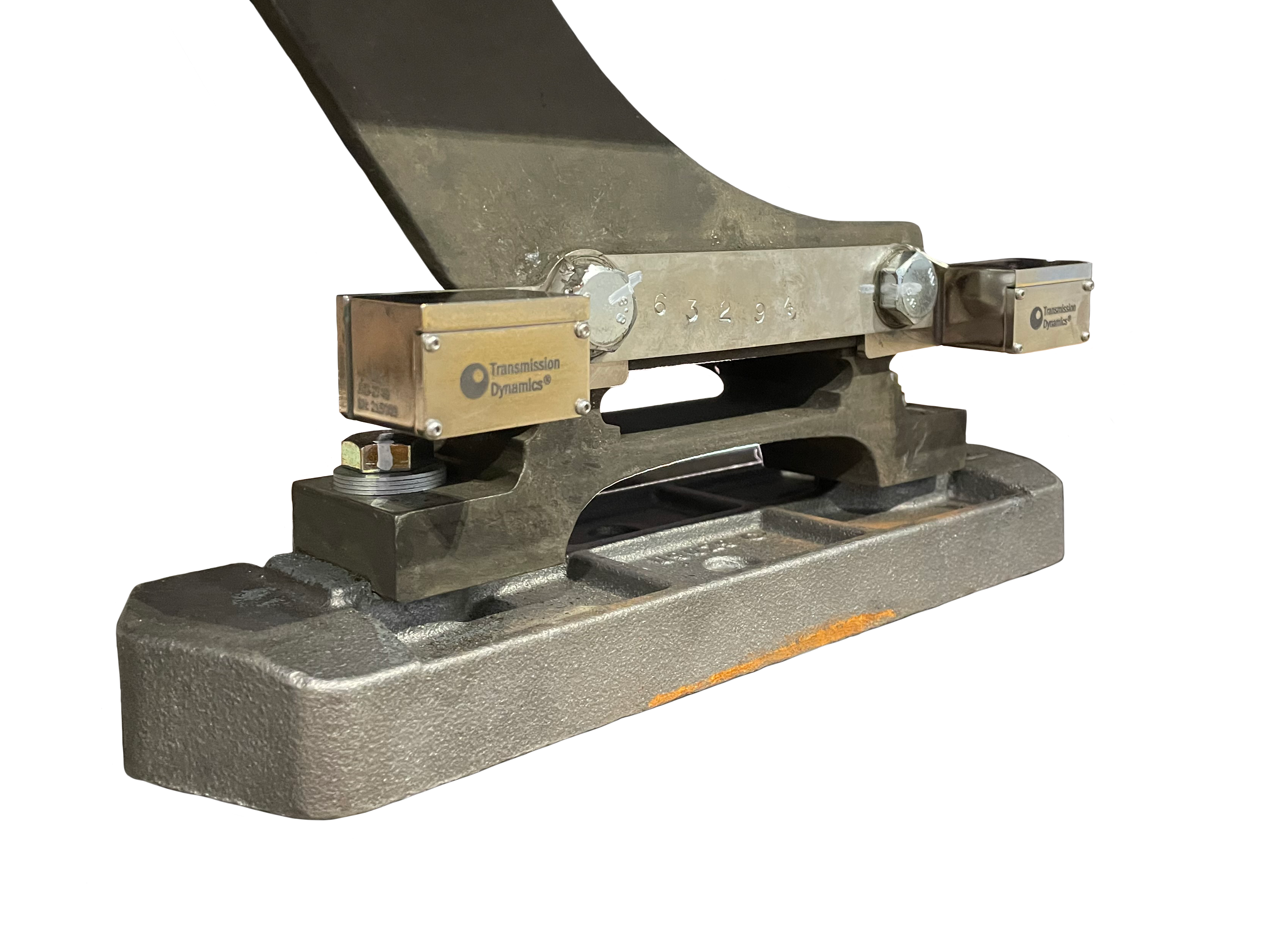

The Smart Oil Plug®, a wireless, electronic alternative to the oil drain plug, monitors gearbox temperature, vibration, and ferromagnetic debris, providing crucial insights into gearbox health and real-time continuous monitoring. The gateway, installed on the bogie, is equipped with accelerometers and gyroscopes, allowing for the extraction of the ride quality of the bogie, just above the primary suspension. Detection capabilities also include, wheel flats, rolling contact fatigue, damper failures, cardan shift failures, and much more.

The ultra-miniature wireless data telemetry systems, SmartBugs® measure strain, vibration, gyroscopic roll, and temperature. These sensors offer unparalleled ease of installation while integrating some of the most powerful data acquisition, logging, and onboard data analytic capabilities available today. Due to their lightweight and small size, these devices can be securely glued to axle boxes and other assets, such as electric motor armature, to monitor the integrity of the entire propulsion system.

Case Study: Combining Intelligence for Holistic Monitoring Solutions

Network Rail’s digital railway strategy set out a blueprint for modernisation, stating the importance of bringing down operations costs of the network, and outlining the benefits of deploying digital monitoring technology to meet those aims. Transmission Dynamics’ Trains with Brains® concept was therefore developed with several key rail stakeholders to deliver a solution for this need.

The Trains with Brains® IIoT solution integrates data from a range of monitoring sensors, creating a holistic view of railway assets and infrastructure to inform Network Rail’s monitoring and planning systems. Deployed on a routinely operating train in the North West and Central Region of the UK rail network, Trains with Brains successfully networks the PANDAS-V® camera system with Smart Oil Plug® and SmartBugs® to provide unprecedented insights into the interactions between the rail and overhead line infrastructure, allowing for complex static and dynamic modelling to be accomplished.

The combined intelligence of networked devices enables significantly more informed maintenance planning within Network Rail, enabling them to reduce delays, unscheduled maintenance, and boots on ballast while improving reliability, safety, and costs. The wider supply chain also sees significant benefits. This solution provides Train Operating Companies with the ability to better understand, evidence, and learn from faults found to continuously improve their service. From a Rolling Stock Leasing Company perspective, Trains with Brains® ensures their assets create value, supporting Network Rail to operate more efficiently and safely, and enabling their customers (TOCs) to deliver the best possible service to passengers.