Pantograph Condition Monitoring System for the Railway Industry

Pantograph condition monitoring can prevent catenary tearing incidents. Detect, analyse to prevent and act!

Predictive Maintenance

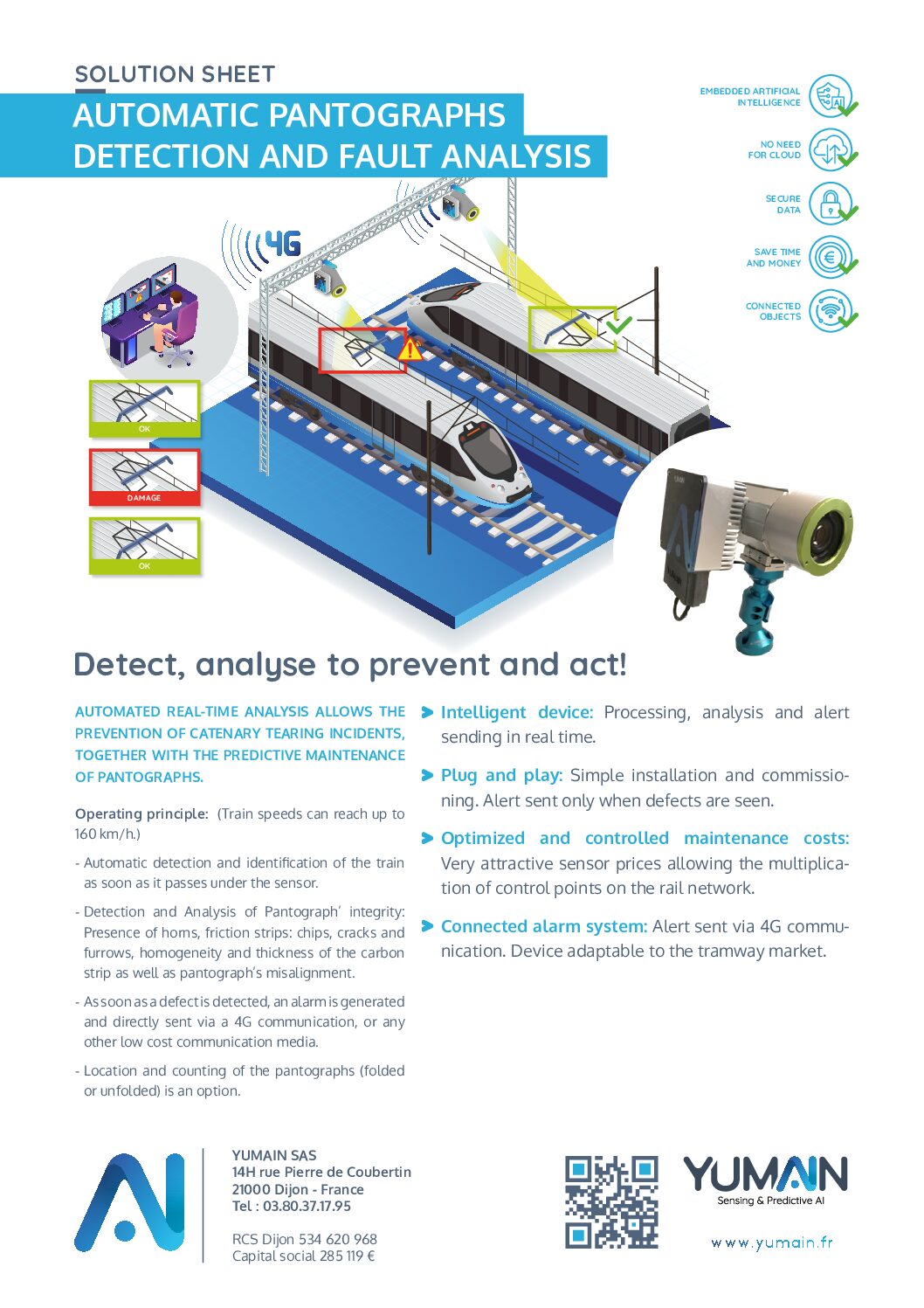

Yumain introduces an intelligent device that processes and analyses the state of the pantograph in real time and sends an alert when a fault is detected. This embedded AI sets a new standard for predictive maintenance and guarantees the end of catenary tearing incidents.

- Optimised and controlled maintenance costs: Very attractive sensor prices, 10x cheaper than other solutions. This enables the number of control points to be multiplied by 10, thus covering the entire rail network. Works on trains in service, so there is no need for manual inspection.

- Intelligent device: Yumain’s system uses an AI (Deep Learning) based architecture. Processing, analysis, and alert sending are done in real time.

- Plug and play: Simple installation and commissioning.

- Connected alarm system: Alert sent via 4G communication to any rail network operator.

- Data security: Alarm sent only when faults are detected. AI embedded in the sensor; the decision process is realised in the sensor.

Fault Detection

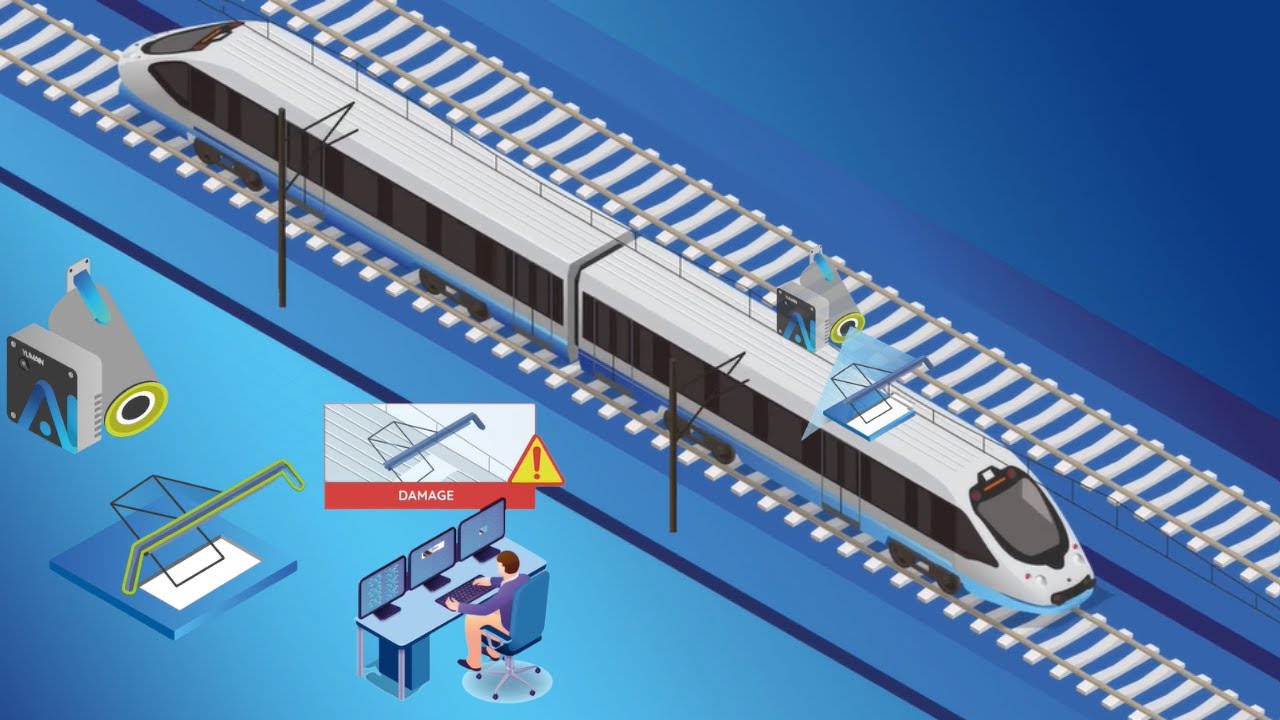

Automatic detection and identification of the train as soon as it passes under the sensor (train speeds can reach up to 160 km/h).

The following items are analysed:

- Pantograph location (folded or unfolded) and counting

- Pantograph Integrity Analysis: Absence/Presence of Horns and Offset

- Analysis of the integrity of the friction strip: scales, cracks, and grooves

- Homogeneity and thickness of the carbon slide plate

As soon as a fault is detected, an alarm is generated and sent to a rail network operator.

Save Time and Money

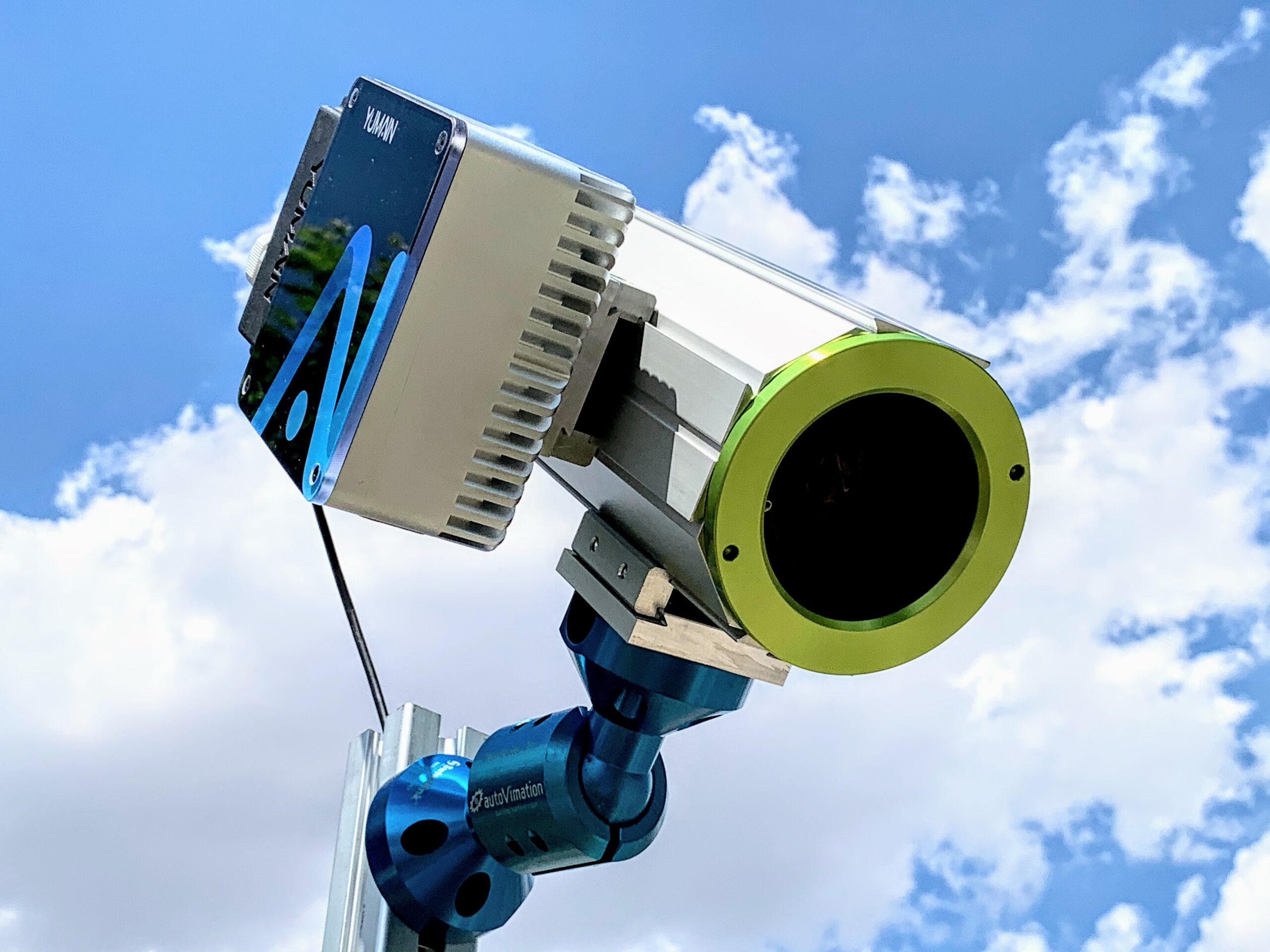

The extremely compact size of the sensor makes it easy to install and integrate into the environment. Two sensors above each track are required for optimum performance.

Installation, calibration, and implementation can be carried out by 2 people and does not require any special equipment or machinery. As the tariff per measuring point is up to ten times lower than more complex solutions, it allows a multiplication of control points (e.g. station entrances) on the national rail network.

At each inspection point, the fixed sensor(s) capture high-resolution digital video images of each piece of equipment. At the same time, the engine number is also read automatically. Real-time analysis (< 5 minutes) is then performed, and an alarm is then generated if necessary, and transmitted by email.

Robust and Reliable

The automatic pantograph analysis device is based on combining the use of robust and mature algorithms, as well as filters applied by image processing.

The Yumain solution is designed to be robust and industrial to respond to the major problem of overhead lines being torn out by defective pantographs.

Edge Computing

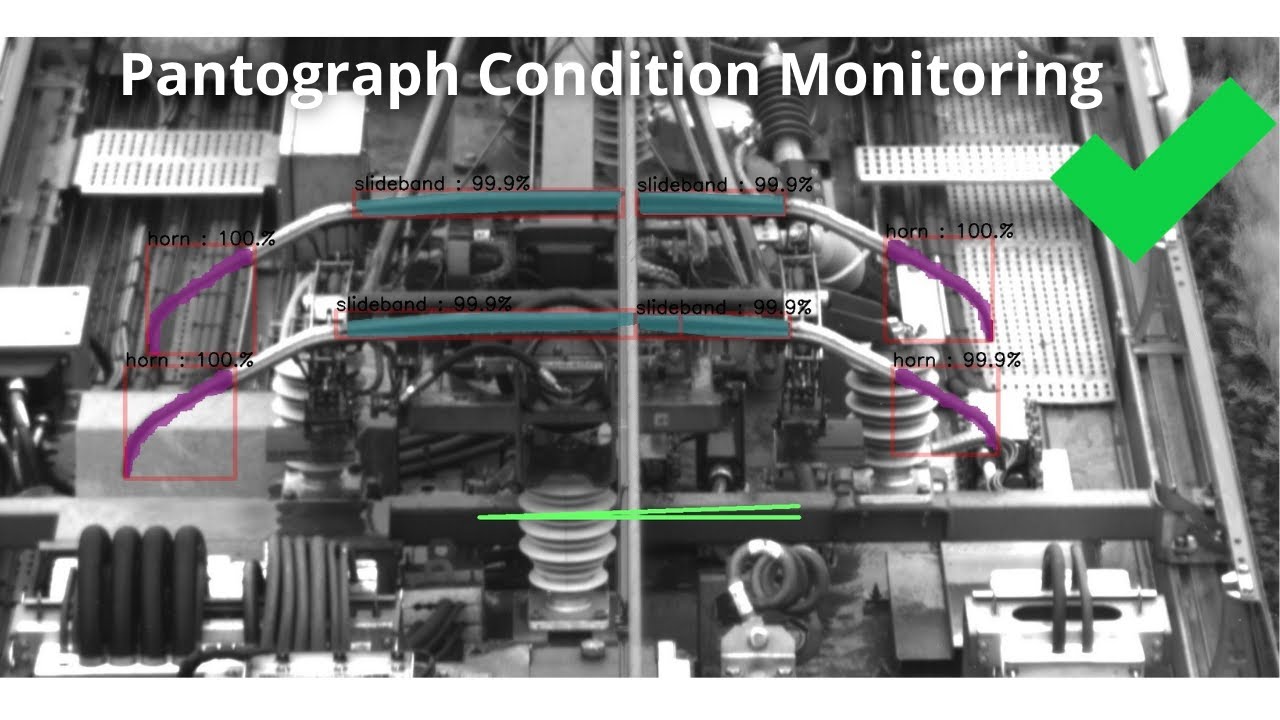

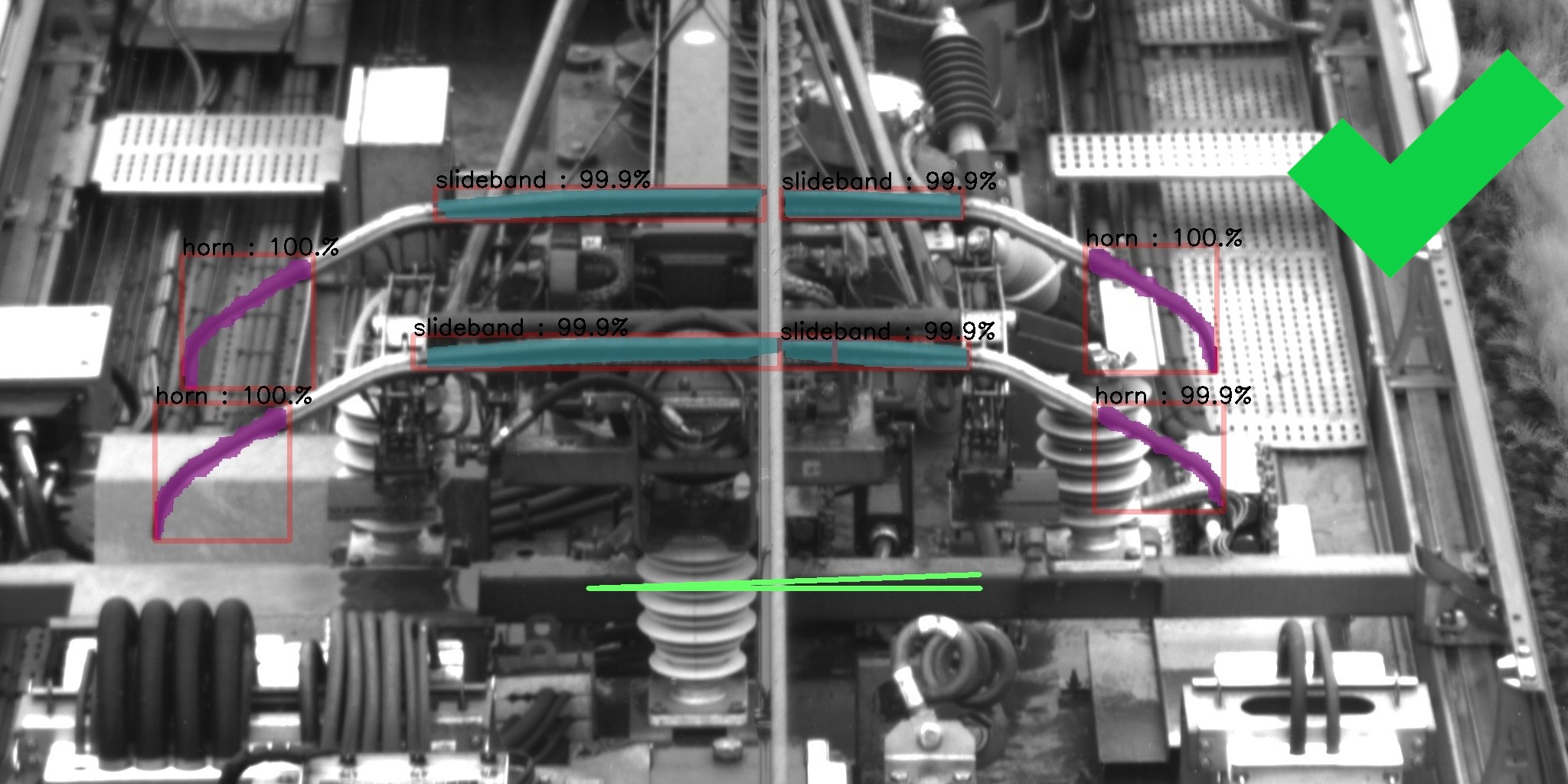

Satisfactory Pantograph

The embedded artificial intelligence, coupled with image processing on a deep learning basis, monitors the detected pantographs for compliance and to locate faults. The process entails locating and detecting the presence of all horns and the location of contact strips. Moreover, it verifies that the pantograph is perpendicular to the train’s axis.

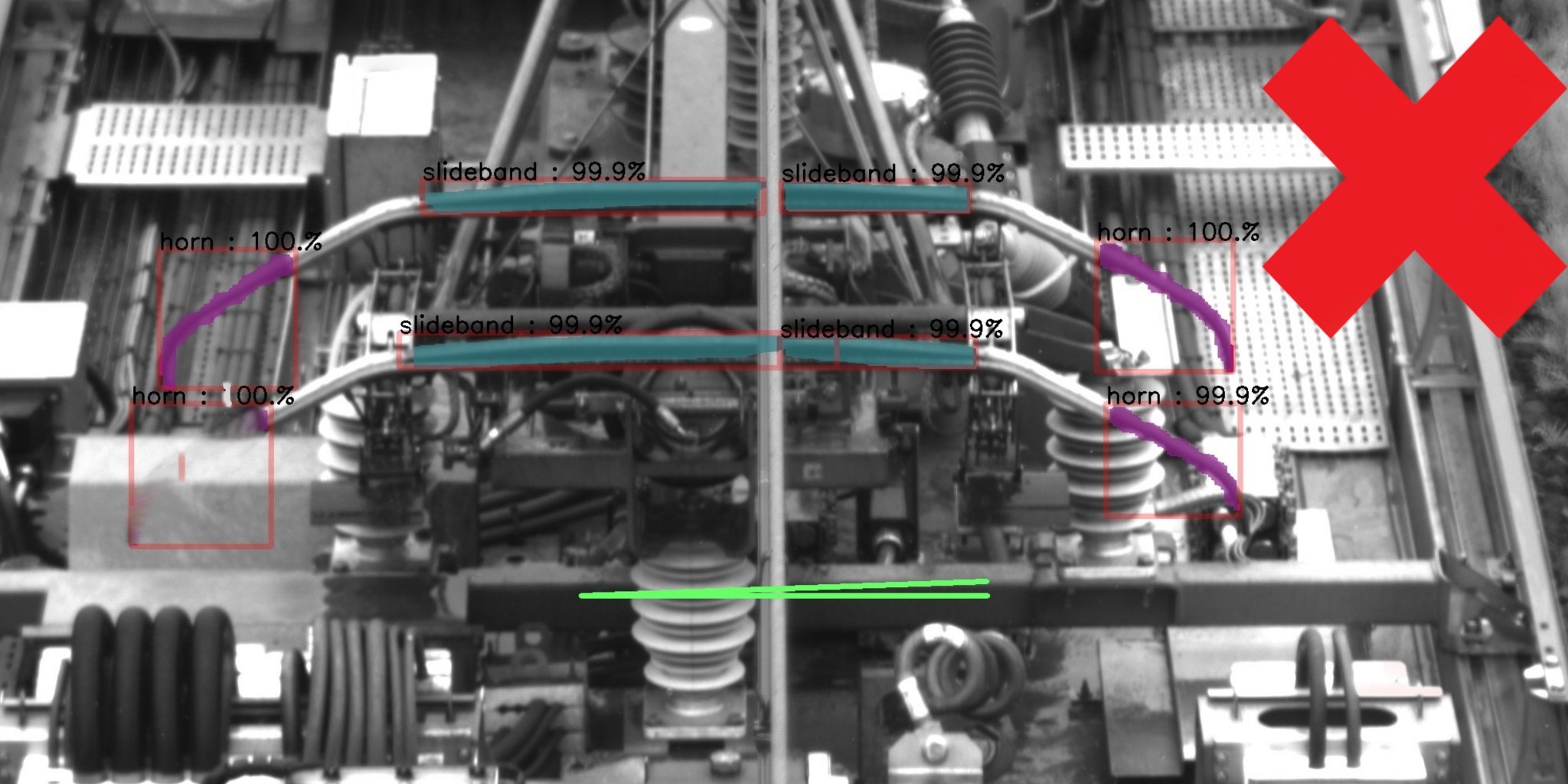

Damaged Pantograph

The embedded artificial intelligence monitors the detected pantographs for compliance, if the pantograph is tilted or damaged, the Edge Computing Sensor (E.C.S.) sends the non-compliance alert to the operator in less than 5 minutes, via the 4G network. It is also possible to add the feature of pantograph counting (raised/lowered). A tilt problem is indicated by red stripes instead of green ones.

Embedded Technologies Trophy

On January 19, 2021, the E.C.S. product, with its pantograph detection and analysis solution, won the Embedded Technologies Trophy in the IoT Industry and Services category. During the “Assises de l’Embarqué”, this Trophy was awarded to Yumain by CEA-List, a partner that has been with us since the beginning and recognised Yumain’s expertise in embedded AI.

About Yumain

Yumain develops AI solutions adapted to all sectors of activity, including the rail industry.

Our embedded or remote equipment and our algorithms using deep learning enable us to offer a range of solutions designed to optimise productivity and safety on site.

Counting, identification of anomalies, protection of people and installations are some of the possible applications of Yumain’s solutions.

Embedded artificial intelligence improves reliability and robustness, and reduces operating costs.

Intellectual Property

We have a 50% joint patent with the SNCF for our pantograph defect detection device.

Our Dedicated Railway Consultant

OCS2 is a French company supplying equipment in the railway sector and catenary installations.

To contact OCS2:

Manager: Jérôme Anselme

Email: [email protected]

Phone: +336 7928 9281

www.ocs2.com

For more information visit our Pantograph Detection and Analysis and E.C.S. pages.