Train Hose Assemblies and Fluid Handling Products

Argus Fluidhandling Ltd has a long history with the Railway sector in the UK, from its first beginnings as Oil Feed Engineering in the 1940s to the current day it has been at the forefront of innovation in hose and tube technology. Operating from two manufacturing locations in the UK and one in Southern Germany Argus are ideally positioned to service the European Rail Sector. The manufacturing operation in Sunderland Argus Powerbend specialises in the manufacture of products for a wide variety of markets from off road vehicles to the rail sector.

Argus Sunderland is expert in turning your designs and requirements into reliable and robust products with the added benefit of ISO9001 and TS16949 certification. Manufacturing capability ranges from 4mm od material to 76mm od material with a range of material specifications or protective coatings from standard electro plating to high quality powder coating. We are able to provide laser cutting and profiling as well as welding, induction and torch brazing, electric and hydraulic bending, notching, pressing, end forming and other customer bespoke operations. The Salisbury manufacturing facility specialises in the production of high specification hose assemblies and hose and tube composite assemblies, ISO 9001, TS169489 and ISO14001 approvals ensure you receive good quality sustainable products.

Hoses for Pneumatic Train Brakes

Working closely with companies in the Rail Sector Argus Salisbury has developed a range of hoses that conform to EN45545 hazard level 3 for applications where low smoke and toxicity levels are required. Designed initially for pneumatic brake applications, RAILSAFE can also be utilised for cooling systems, Pantograph Systems and any other low pressure fluid or gas application.

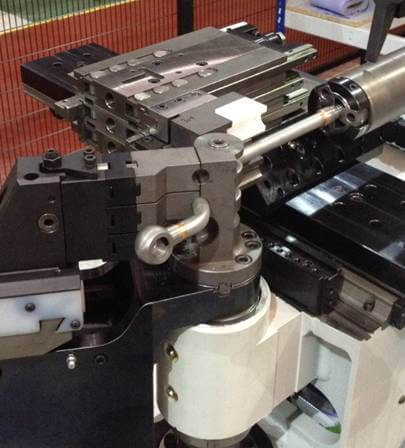

A range of fittings are available in different materials from mild steel to stainless steel depending on your application, end fittings can also be electro plated in a variety of specifications. For ease of assembly and to reduce assembly times Argus has a range of low pressure threadless connectors available, the system is a simple push to fit arrangement negating the need for bulky and awkward hand tools.

Threadless Connectors for Locomotives

It has the added benefit of allowing the parts to swivel when connected whilst remaining leak free, the quick connect system also eases disassembly for routing maintenance or overhaul. Argus Salisbury is also able to offer tube manipulation as part of a packaged supply incorporating the threadless connectors and Railsafe hose including kitting of components if required. As well as special products for the Rail Sector Argus is also able to supply a standard range of hose and fittings for hydraulic and pneumatic applications.