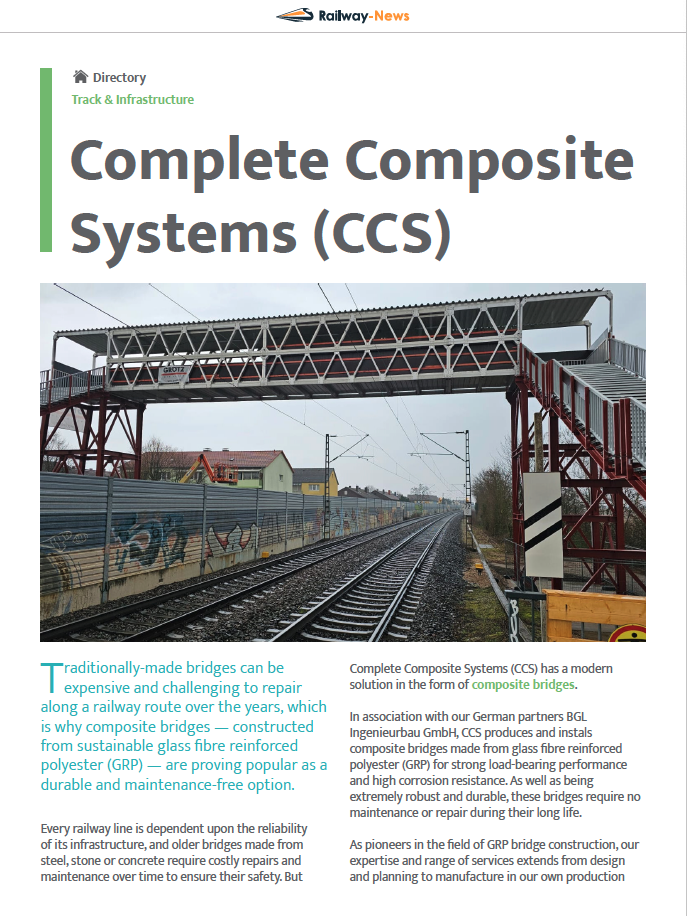

Complete Composite Systems — Expert Composite Plastic Engineers Serving the Rail Industry

Complete Composite Systems designs, manufactures and installs standard and bespoke composite and engineered plastic systems for challenging rail infrastructure across the world.

Our products are constructed from the finest quality materials, tested to the highest standards and proven to work in the most demanding conditions with unsurpassed reliability compared to traditional materials.

Composite Systems for Rail Applications

CCS has over 50 years’ hands-on experience with composites and engineered plastics. Combined with leading expertise in FEA and CAD software, we provide an unsurpassed level of product knowledge, service and performance. Our cable management systems can be found in rail networks across Europe, the Middle East and beyond.

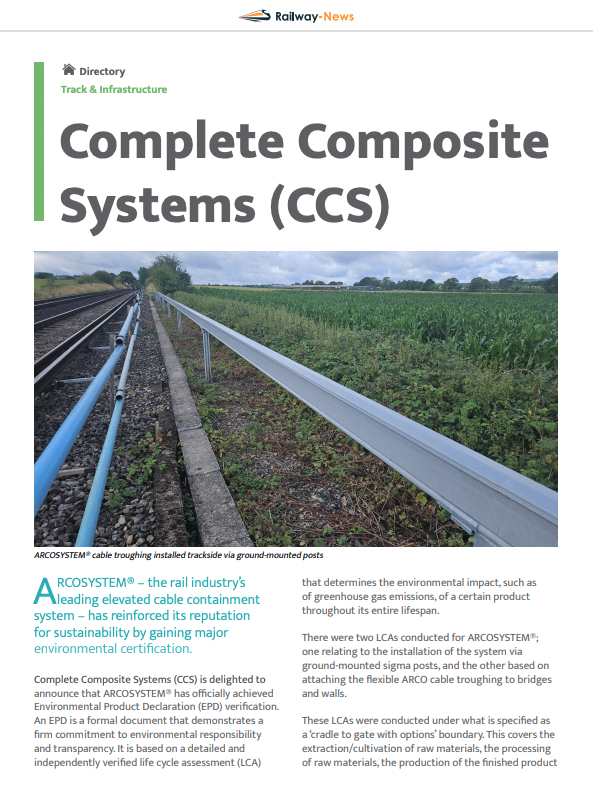

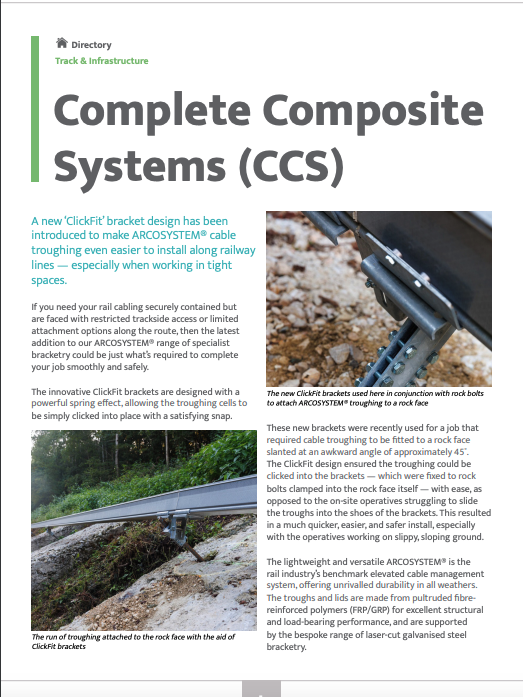

ARCOSYSTEM is an extremely versatile elevated cable management system. Designed to be post-mounted, wall-hung or fixed to line side structures at six-metre centres, the system uses a dedicated range of bespoke bracketry that enables height and direction changes to be safely accommodated with ease. As well as being resistant to water and a wide range of chemicals, the system’s lightweight structure makes it easy to install, ensuring installation times and labour costs are dramatically reduced.

TECHNO-CRETE is an environmentally-friendly post mix designed to securely hold fence posts, elevated troughing and signage in place. It is a two-part, high-density hydrophobic polyurethane based upon a blend of reprocessed oil from the catering industry and sustainably grown rape seed oil. Once mixed, the blend foams to form a structurally robust, solid foam. Its two-pack system is hand mixed and doesn’t need water. One 1.8kg pack replaces three 20kg bags of concrete post mix, significantly reducing transportation costs and injury risks from manual handling. Using TECHNO-CRETE instead of cement-based concrete in 1,000 holes (300 x 600mm diameter) saves over 10 tonnes of CO2 emissions from entering the atmosphere, the equivalent of over ten return flights from London to New York.

TERRASYSTEM is a tough, UV-stabilised ground-mounted cable management system. It’s also lightweight and impact-resistant, making it an easy product to handle and install on-site. TERRASYSTEM’s interlocking troughs and lockable lids make it a safe, secure system with excellent fire and toxicity performance. Ideal for use in a wide range of temperatures, TERRASYSTEM is being used everywhere from the frozen wastelands of Greenland to the desert sands of Saudi Arabia.

TouchSafe FRP Composite Palisade Fencing is made to offer a strong, safe and non-conductive barrier to screen electrical equipment or hazards. The panels are manufactured from pultruded profiles and cross angles that are interlocked to form a robust structure. There is no need for maintenance and less chance of damage from potential vandalism incidents. As composites are natural electrical insulants, the fencing provides a non-conductive boundary for the safe containment of electrical equipment on rail applications such as substations, LOC suites, and OLE masts.

Case Study: Efficient and Easy Elevated Troughing with ARCOSYSTEM

Rail industry projects often face challenges such as congested infrastructure, old and new technologies merging, or ground conditions proving difficult. When railway engineering contractors Haigh Rail Ltd had one such project at Greenbank Station in Cheshire, England, ARCOSYSTEM — the elevated cable management product — was the perfect choice.

Haigh Rail was tasked with the installation of new elevated troughing for the holding of a 650v power cable. The design of this particular trough route was more unusual than most. Ground investigation revealed conditions were very poor and that the usual 1.9m posts with 600mm foundations were simply not going to cut it. Instead, 4m posts were required to give the route the anchor it needed. This required bespoke posts and bracketry to support the troughing which had been specified for the project.

ARCOSYSTEM was chosen due to the technical ability of its manufacturer to create bespoke products with ease and at speed. The custom-made bracketry required for the Greenbank Station project took just five weeks from concept to delivery.

Chris Haigh, Managing Director of Haigh Rail, said of ARCOSYSTEM: “It is simple to install, we had no site issues and everything went smoothly. We were achieving 24 posts and 15 lengths (90m) of route in four hours, which is amazing considering we were pushing in 4m posts, utilising an RRV and we found lots of buried cables in the way. This was by no means a perfect area.

“The product looks great and our client is happy. We did need additional materials midway through the scheme which was sorted efficiently by Scott Parnell, the UK stockist of the product. Scott Parnell provided a great service overall, very efficient staff and supply. I would highly recommend ARCOSYSTEM as it is simple to install.”