The British rail regulator, the ORR, has made a number of regulations after reviewing how the rail industry handled the potential safety issues that caused the Hitachi Class 800 trains to be withdrawn from service in May 2021.

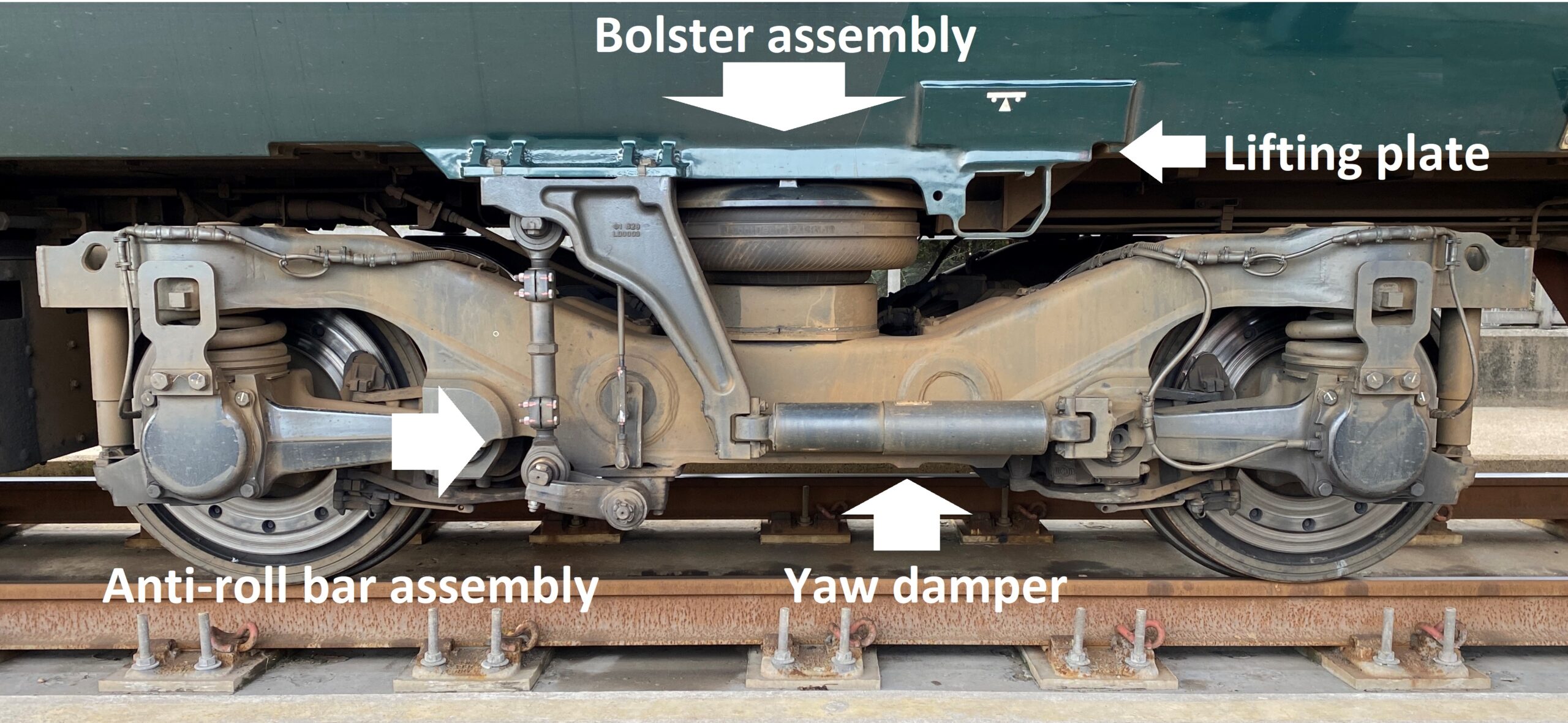

Cracks were found on the bodyshell (yaw damper bracket and anti-roll bar fixing points) of some of the trains, after which Hitachi Rail and the relevant train operators conducted safety checks, overseen by the ORR.

Next, rigorous mitigation measures were implemented so that the trains could go back into passenger service without safety concerns.

The ORR immediately launched a review of the passenger and safety impact on Great Western Railway (GWR), London North Eastern Railway (LNER), TransPennine Express (TPE) and Hull Trains. It should be noted that cracks were only found in the trains operated by GWR and LNER, while those of TPE and Hull Trains were withdrawn on a precautionary basis. Cracks were separately discovered after examination on ScotRail’s Class 385 and Southeastern’s Class 395 trains. These were not withdrawn from service at the time as their designs are different and the issue was assessed as low-risk.

Both the manufacturer of the trains, Hitachi Rail, and independent experts have performed in-depth analyses to understand the issue.

“on the vehicle body in the area above the wheels close to the yaw damper bracket and anti-roll bar fixing points, fatigue cracking was caused by the trains experiencing greater loads from train movement than allowed for in the original design. It is not yet known for certain why this happened, although potential factors include wheel wear and track design.”

Further cracks were found in the area where the lifting plates attach to the vehicle body. These were caused by stress corrosion cracking, resulting from the use of the particular type of 7000 series aluminium in various areas of the trains affected.

“The characteristics of the specific aluminium alloy in combination with built-in stresses from being welded to the body and exposure to air containing chloride resulted in cracking.”

ORR Recommendations

- The industry should look further into why rolling stock experiences higher levels of fatigue loading

Hitachi’s design complied with industry standards so the industry as a whole should evaluate whether the applicable standards take into account the loads arising from operation on the British rail network. - Hitachi Rail should carry out a formal review of the effectiveness of their processes for welding when the component geometry is more challenging

This review should also consider whether the existing approach adequately mitigates the risks of a weld with insufficient fusion being accepted. - Rolling stock designers should understand the risk posed by stress corrosion cracking

They should give it special consideration when suggesting the use of 7000 series aluminium components. That does not mean that this type of aluminium should not be used anymore or that it is not safe in the trains where it is currently used. - The industry should consider whether a standard for mitigating stress corrosion cracking risk should be developed

- The industry should develop a process for responding to similar future cross-industry crisis events and appoint a strong, independent chair

The ORR continues to carry out oversight.

Hitachi Rail and its industry partners will shortly embark on the major programme of work to repair 1,247 Class 800 series vehicles and a further 487 Class 385 and Class 395 vehicles.

Meanwhile, the ORR is working with Hitachi and its partners to develop a permanent solution to address the problems.

- replace the affected part of the original body structure, including the longitudinal welds where the fatigue cracks occurred and the mounting brackets

- modify the addition of bolts to retain the plate in the unlikely event that the welds fail completely as a result of stress corrosion cracking

This work is to take place over a period of six years to minimise disruption.

The ORR has praised the industry’s rapid respond and work to allow the trains to be reintroduced to passenger service safely.

“With our oversight, Hitachi Rail and operators have put in place robust plans to make sure the right safety issues are being managed following the initial discovery of cracks on the trains, which have allowed trains to re-enter service.

“Safety remains the number one priority. Our review provides a clearer picture of the issue and we will continue our oversight to ensure work moves forward to agree the permanent solution and our recommendations are acted on.

“It is important that the whole industry works together to learn lessons from what has happened and our recommendations will help with that.”