Televic GSP

Smart Lifetime Extension Makes Your Railway Fleet Last

This article first appeared in the Railway-News magazine, Issue 1 2023.

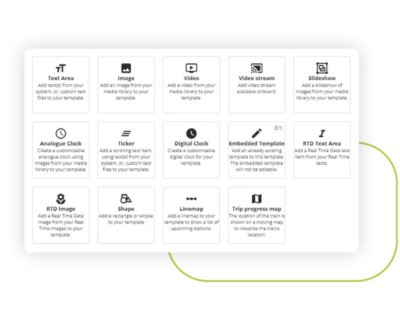

Intelligent technology is becoming increasingly decisive for passenger information systems. Consequently, the maintenance of your software deserves as much attention as that of your infrastructure. A new approach is therefore required, especially since market trends are pushing for more sustainable solutions.

Growing Complexity and Importance of Software

The basics of passenger information system (PIS) maintenance have not changed. They are still mainly focused on repairs and spare parts. The complexity of integrated electronic devices, however, has increased enormously over the years. No wonder, with PIS getting more and more interconnected and delivering more detailed information in real time.

Relying on PIS support is vital if you want to keep both your hardware and software in pristine condition.

“Historically, a lot of effort has been put into the close monitoring and maintenance of rail vehicles’ hardware devices.

“But the same effort should go into regular software check-ups and updates. This is a mindset that is not yet fully established, even though PIS are now packed full of sophisticated software. It is important to understand that the intelligent technology that is being used today simply will not live up to the industry standards in, say, 10 years’ time.”

The Search for Sustainable Solutions

A different approach towards the after-sales services for rail vehicles is needed if you want to make the best use of your resources. Not only because of PIS devices’ ever-increasing complexity, but also because the next emerging trends are propelling a growing demand for sustainability in the industry.

Green Technology

To avoid obsolescence and unnecessary waste of materials as much as possible, train builders and operators are increasingly looking for long-lasting support to face challenges that come with ageing equipment. This means that spare parts or like-for-like replacements should remain available for repairs during their fleets’ entire lifetime.

“That is why we already take into account the need for longer product and component lifetimes from the design phase onward, an approach we follow for both software and hardware. By effectively planning for the future, we are safeguarding continuity in the event that components break or malfunction.

“Next to that, we are using components based on the latest state-of-the-art technology for repairs. For instance, today’s used capacitors have better properties and often a longer lifetime than 10 years ago.”

Intelligent Obsolescence Management (iOM)

Continuous technological advances keep enhancing your PIS, and thereby passenger satisfaction and on and off-board safety. At the same time, these automatically imply that your system will be more quickly prone to obsolescence.

The Answer: Services Focused on Smart Lifetime Extension

Maintaining PIS devices and software punctually, and carefully anticipating obsolescence are key to keeping your fleet running as long as possible. But organising the processes involved is no easy task. That is where our services team can make all the difference.