Railway safety goes beyond trains stopping at the signal: monitoring the bogie level is just as important.

With COSAMIRA, Televic GSP provides a single integrated solution incorporating key elements of condition-based maintenance as well as instability monitoring and derailment recognition.

Often, when train operators raise concerns on safety issues, trains passing a stop signal without authority are what comes to mind. Or you’ll think of interactions between trains and the public: people carelessly or accidentally crossing the tracks at stations or crossings. While this is rightly the case, monitoring trains at the bogie level is equally important.

European Regulation Demands Onboard Data Diagnosis

The European Technical Directive for Interoperability number 96/48 EC stipulates that continuous and reliable feedback is vital to immediately detect bogie-level damage. For Class One trains, there is an additional requirement for onboard data diagnosis to ensure traceability, a so-called black box.

Proactive Monitoring Improves Safety

In the past, onboard bogie-level safety systems were mostly operated independently. However, a condition-based maintenance system uses big-data technology to monitor key applications simultaneously. This ensures a single source of information to provide insights into all aspects of train safety, at all speeds and under all operating conditions.

When using a condition-based maintenance system, information such as acceleration and temperature is tracked by software algorithms. This generates multiple datasets, ranging from critical insights to recommendations on a daily basis. As a train operator, you can access this data in a single interface to monitor all key statistics at the same time.

COSAMIRA: Encompassing, Yet Unparalleled

With COSAMIRA, Televic GSP provides a complete proven solution for train and track condition-based maintenance. This means you can now access all essential data in one place. COSAMIRA is built on thirty years of experience and in conjunction with major train builders.

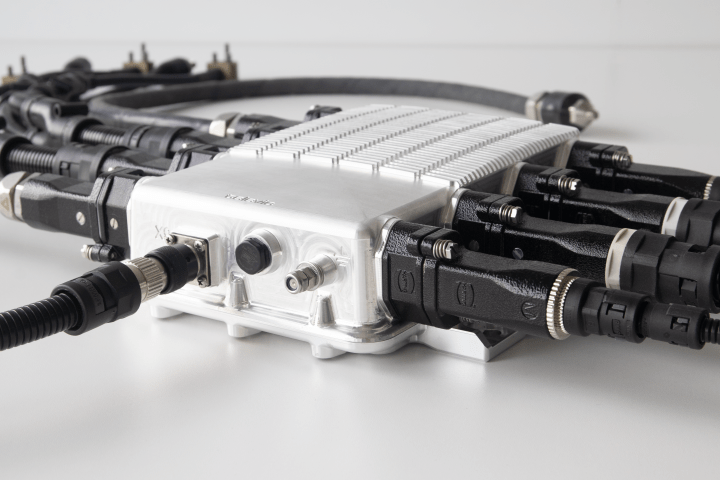

Moreover, COSAMIRA uses internal accelerometers and gyroscopes to collect and analyse safety data with unparalleled capability. Safety and maintenance monitoring is therefore combined in one unified package for maximum return on investment. Not unimportant: interaction or integration with legacy systems is supported.

With COSAMIRA you can monitor wheel flatness and detect anomalies. But there is a whole lot more. The condition-based monitoring system allows you to track:

- wheel-bearing wear

- hot axle box

- gearbox and traction motor

- instability and derailment recognition: accredited to EN50155, EN50121-3-2, EN45545 and SIL2

- safety certification

- tilt-failure recognition (the detection of wheel unloading)

- gauge infringement

- excessive sidewinds and blocked actuators

This article was originally published by Televic GSP.