The Environmental and Sustainability Impacts of Condition-Based Maintenance in Rail Transport

The quest for sustainability is gaining momentum, and innovative approaches to maintenance are paramount.

One of them is Condition-Based Maintenance (CBM). This proactive maintenance approach enhances the reliability and efficiency of trains and contributes significantly to environmental and sustainability goals.

Historically, train operators have relied on scheduled or reactive maintenance practices, often leading to inefficiencies and unnecessary resource consumption. Routine maintenance schedules, while necessary, can result in overhauls or replacements that might be premature if based solely on time-based criteria.

This traditional approach not only adds to operational costs but also has significant repercussions, considering the energy-intensive nature of maintenance procedures and the disposal of components.

A Paradigm Shift

Condition-Based Maintenance marks a paradigm shift in how trains are maintained. Instead of adhering strictly to predetermined schedules, CBM leverages real-time data and advanced analytics to assess the actual condition of components. This approach enables rail operators to intervene precisely when needed, optimizing the life cycle of critical assets and minimizing unnecessary maintenance activities.

Reducing Waste: CBM’s Impact on Resource Consumption

One of the most significant contributions of CBM to sustainability is its ability to reduce waste. By accurately assessing the condition of components, rail operators can avoid premature replacements, extending the life of critical parts. This conserves valuable resources and minimizes the environmental footprint associated with manufacturing and disposing of components.

Consider the impact on rail tracks, for example. Traditional maintenance might dictate replacing a section of track based on a predetermined timeline. In contrast, CBM allows for a more nuanced approach, replacing sections only when their condition warrants it. This results in reduced waste and a more sustainable use of materials.

Energy Efficiency: CBM’s Role in Operational Sustainability

Maintenance activities, especially large-scale overhauls and replacements, are energy-intensive processes. CBM’s ability to target maintenance efforts precisely translates to fewer overall maintenance activities, reducing the energy consumption associated with these processes.

Furthermore, by preventing unexpected failures through predictive analytics, CBM contributes to the overall reliability of rail systems. Trains can operate more efficiently when the risk of breakdowns is minimized, leading to energy savings and a smaller carbon footprint over the long term.

Smart Technologies Driving Sustainability: Sensors, IoT, and Beyond

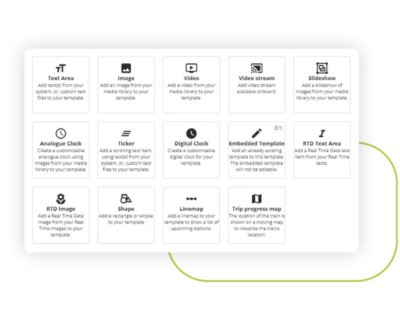

At the heart of CBM’s success in driving sustainability are smart technologies such as sensors and the Internet of Things (IoT). These technologies enable continuous monitoring of critical components, providing a wealth of data that feeds into predictive analytics models.

Sensors placed strategically on trains can detect subtle changes in temperature, vibration, and other indicators of wear and tear. This real-time data allows maintenance teams to identify potential issues before they escalate, facilitating timely interventions and reducing the need for emergency repairs.

Challenges on the Track: Addressing Environmental Concerns in CBM

While CBM brings significant environmental benefits, it has challenges. The increased reliance on sensors and data analytics raises questions about the environmental impact of producing and disposing of these technologies.

However, these challenges present opportunities for innovation. Sustainable practices in the manufacturing and disposal of sensors and advancements in energy-efficient technologies can mitigate these concerns. As the industry evolves, it is crucial to address these challenges collaboratively, ensuring that the environmental gains of CBM are maximized.

Looking Ahead: The Future Landscape of Sustainable Rail Transport

The adoption of CBM represents a crucial step toward a more sustainable future for rail transport. As technology continues to advance and the rail industry embraces innovative solutions, we can expect even greater strides in sustainability. Artificial intelligence, machine learning, and further integration of smart technologies promise to refine CBM approaches, making them even more precise and environmentally friendly.

In conclusion, Condition-Based Maintenance is a beacon of sustainability in the rail industry. By reducing waste, optimizing resource use, and promoting energy efficiency, CBM is enhancing the reliability of rail systems and aligning the industry with broader environmental goals. As rail operators prioritize sustainability, CBM will undoubtedly play a central role in shaping the future of eco-friendly and efficient rail transport.

This article was originally published by Televic GSP.