Every year, we see and work with more and more train operators who are making the switch to condition-based maintenance.

They show and remind us how important it is not to provide an additional stand-alone system, but instead, one that is fully integrated and seamlessly connected to their current systems and technology.

Separate Technologies

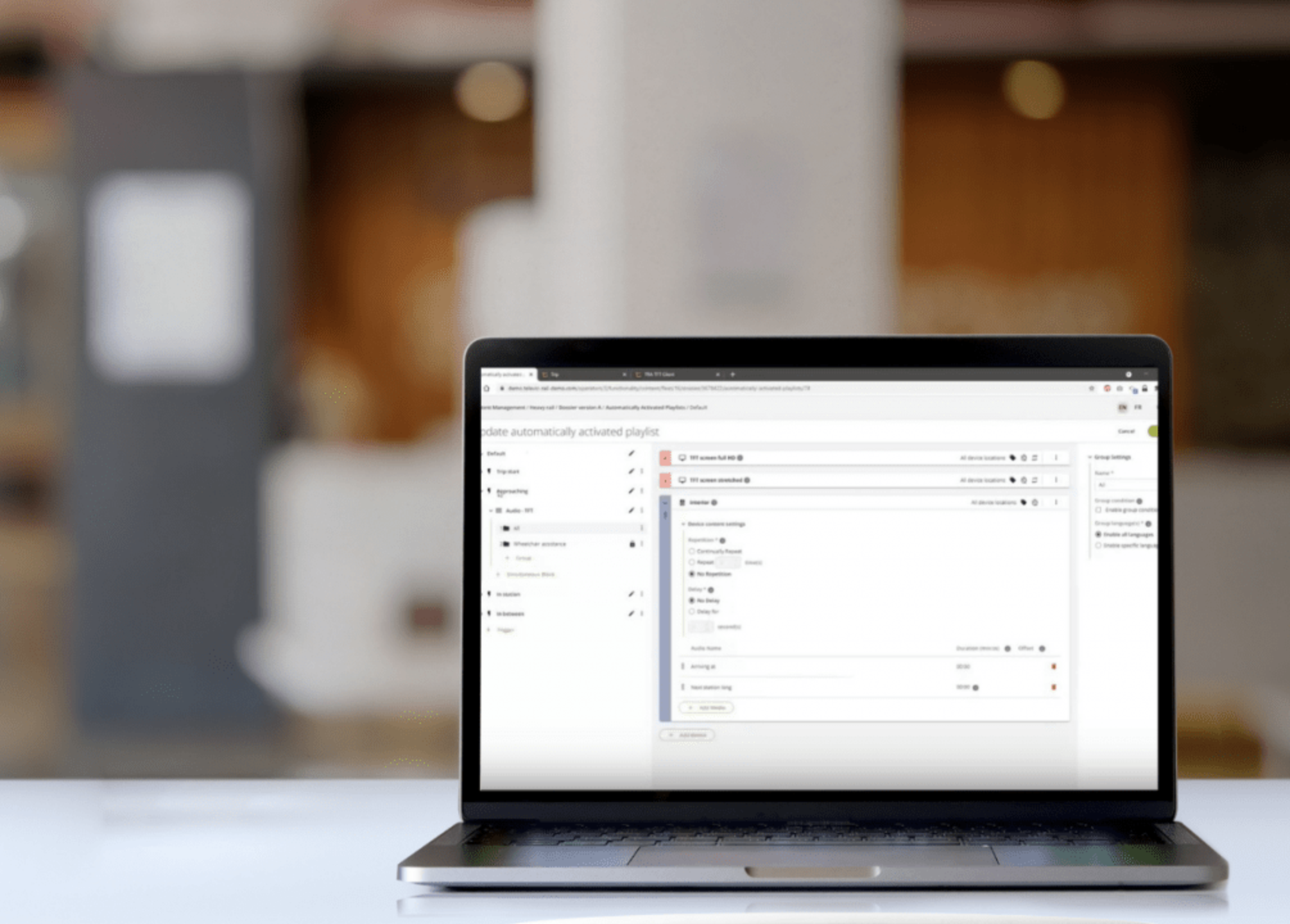

Often, train operating companies have separate technologies that function well to monitor or report a single component or system (e.g., doors or HVAC), but that are not interconnected to the other parts of the train. Such systems are no longer sustainable. Today, as an operator, you want all information presented on a single screen, accessible for everyone who needs to see it, in a unified and clear structure and in your chosen language.

That’s Where COSAMIRA Comes In…

To meet these requirements, our engineers have developed COSAMIRA: a complete solution to enable immediate, clean and reliable connection to all the major train builder and maintenance company software systems, allowing the rapid development of interfaces for new technologies.

The result?

Train operators get to see what they want: a single source of information and truth, detailing all the vital maintenance information together with decision-supporting recommendations for all elements on the train.

Covering everything from wheels, bearings, traction motors, doors, gearbox, tracks, catenary, brakes, pumps and pantographs to HVAC.

The 5 Vs of Big Data

Given the fact that (1) data are nothing but numbers without analysis and that (2) modern trains are filling up the “data lake”, it is important to reiterate the 5 Vs of big data: volume, velocity, variety, veracity and value. For you, as an operator, it is of the utmost importance to be able to transform your data from numbers into considered decisions.

In time, the digital integration of complementary systems will intensify and become the standard. Today we are receiving an increasing number of requests to integrate data with ERP systems, so the entire maintenance process can be automated, enabling the autonomous pre-positioning of spares, tools, manpower and other resources to ensure maximum efficiency and reduce costs.

To conclude: the entire rail industry is moving towards greater digitisation and integration of systems, as accessing and understanding the combination of data has never been more important. So don’t miss that train!

COSAMIRA: Your 360° Bogie Control and Monitoring System

With COSAMIRA, an integrated solution for condition-based maintenance on all types of trains encompassing sensors, hardware, analytical software and dashboards, you can…

- reduce maintenance costs through early detection of likely failure with predictive analytics

- improve reliability by monitoring the real-time operational condition of your trains and tracks

- maximise passenger experience by measuring passenger comfort, tilting and active radial steering

Learn more about COSAMIRA here.

This article was originally published by Televic GSP.