Our innovative foam foundation material TECHNO-CRETE® once again proved to be a quicker and more cost-effective solution than concrete post mix during a trackside infrastructure project in Wales.

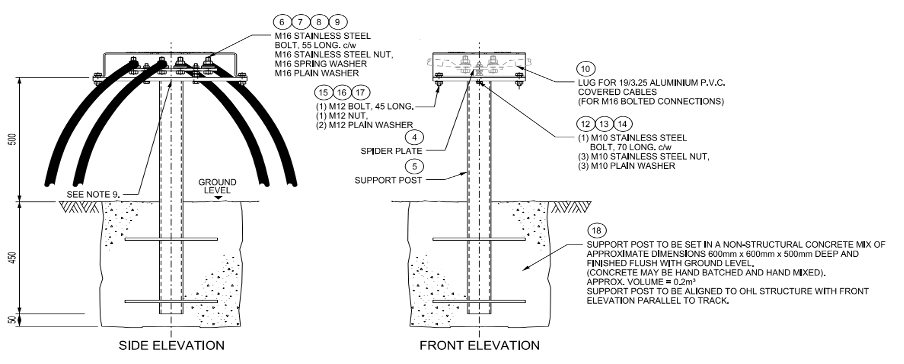

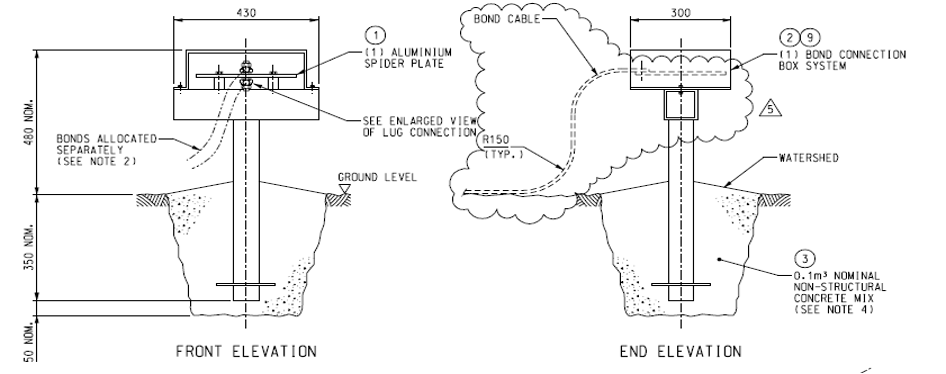

The job required installing GMSPs (ground monitoring spider plates) at multiple locations along the Core Valley Lines Upgrade project across South Wales.

Rail engineering specialists Enable Infrastructure carried out the installation and said: “During our IDC/design stage with our client we had multiple locations that were required to install GMSP as per design. Due to access being a distance away from the location we soon realised the issues and high costs that were involved. Design of the base for the GMSP utilising concrete mix would require a minimum of 12-17 bags of concrete. The complete involvement would be concrete, water, mixing tray additional labour, track trolly or possibly RRV to load out all the materials. This required great effort by the team to install 5 per shift and a lot of planning.”

They decided to look for an alternative method, contacting Ian Allwright at Scott Parnell, our UK partners and stockist of TECHNO-CRETE®, a hydrophobic polyurethane foam foundation system. Available in two packs, part A of TECHNO-CRETE® consists of a blend of recycled organic mineral oils from the catering trade and sustainably grown rapeseed oil, while part B contains isocyanate. When the two packs of liquid are mixed and poured into a hole in the ground around a post, the liquid blend expands to create a lightweight, high-density foam that encapsulates the post, which is hard enough to fix to within one hour.

“Ian Allwright was quick to come back to us with an alternative method that involved using a two-part liquid foam solution. Ian provided us with the specifications and a design below that we put through to our clients. Whilst we were in discussion, we calculated the cost versus actual and realised that there was a huge saving for the client and involved less planning for Enable to programme works.”

“Using TECHNO-CRETE® was a game changer. Realising very quickly that we could achieve multiple locations due to not having to plan/load/organise logistics and allow time for manual handling to carry all the materials and equipment to complete 5 locations covering miles of track between each one during short possessions.

“Below you can see the design that we relayed to client. We also demonstrated we could achieve the same outcome with less cost, less manual handling and less logistical work. All installations were carried out successfully.”

For more information about TECHNO-CRETE® and how it can be used as an alternative to cement-based products, contact our technical experts at CCS. TECHNO-CRETE® is available from our exclusive UK rail stockist, Scott Parnell.

This article was originally published by Complete Composite Systems (CCS).