SKF and Televic GSP Aim to Collaborate to Offer Advanced Maintenance Intelligence for Rolling Stock Operators

- SKF and Televic GSP have signed a letter of intent (LOI) to explore the possibilities to collaborate to increase customers’ rolling stock reliability and reduce maintenance costs by providing the next generation condition monitoring and data analysis.

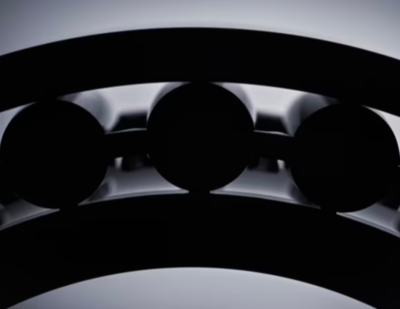

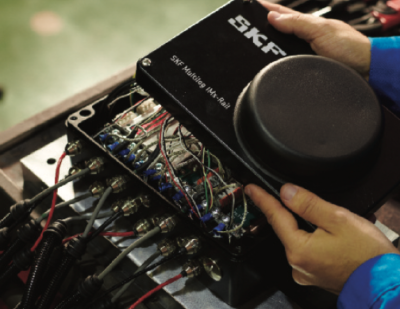

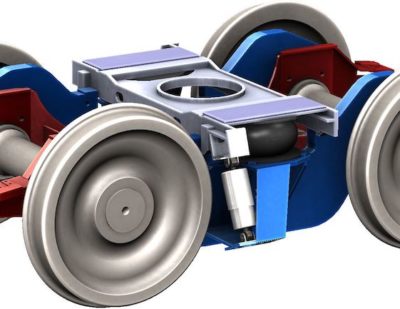

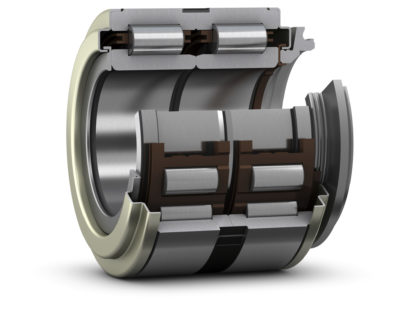

SKF and Televic GSP have announced an intent to collaborate with the aim to drive development and innovation to advance condition-based maintenance capabilities for rolling stock operators. The aim of the potential future collaboration is to combine of SKF’s 100+ years of rotating machinery expertise excelling in proven algorithms and smart solutions for railway bearing damage detection and diagnosis with Televic GSP’s expertise in bogie mounted hardware solutions for data collection and edge computing.

“We see great value in bringing external competencies to complement SKF’s offer. Televic GSP is a trusted partner with many train builders and operators with a long and successful history in developing and producing on-board control and information systems. With the aim of combining our strengths, we want to drive innovations to enable our customers to run their trains more reliably, and with less downtime due to unnecessary maintenance or unplanned stops. These are important steps in meeting, and even surpassing both sustainability and business goals.”

SKF and Televic GSP’s ambitions in exploring a collaboration are to develop end-to-end digital solutions – ranging from data collection to actionable information visualization and reporting – to provide crucial maintenance intelligence. Aiming to provide safe and reliable maintenance interval extensions – via fully deployed advanced algorithms for data analysis, bearing application knowledge and fully integrated product life cycle services – it will allow train operators to reduce downtime, while actionable insights into rolling stock increase uptime and train availability.

“We are looking forward to further discussions and agreements in our way towards a commercial working relationship together with SKF. The way forward is in a data-driven approach to risk management and maintenance strategies. This will, ultimately, enable the industry to make better decisions based on data and meaningful actionable information.”

This article was originally published by SKF.