Britain’s largest train operator, Govia Thameslink Railway (GTR), has installed a condition monitoring system developed by SKF to help avoid unplanned maintenance and the associated disruption to train services.

For any train operator, maintenance plays an important role in keeping rail services running and avoiding potential costly unplanned repair stops. For the rail industry, inspection and reactive maintenance routines are vital for the safe operation of the railway and for the safety of all who travel and work within the industry.

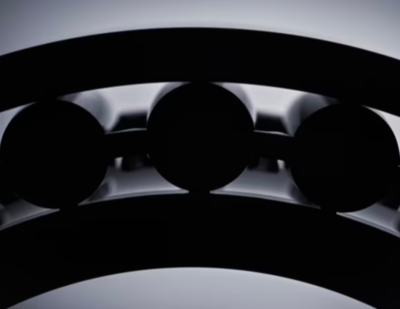

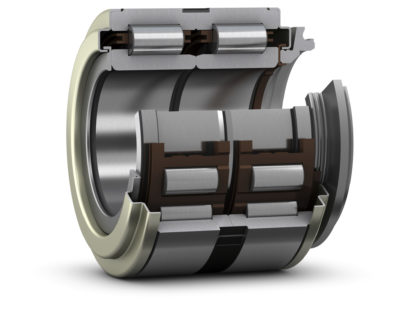

Condition monitoring has been proven in other industries to be a key technology in driving down maintenance costs and extending maintenance intervals through the early detection of potential bearing failures. To meet the unique requirements of the railway industry SKF has developed its own condition monitoring system, called SKF Insight Rail.

“The railway industry is seen as the last frontier for condition monitoring. The complexity of traditional measurement systems was an obstacle for acceptance of the technology.

“SKF has overcome this barrier with a non-intrusive solution that can be easily installed on entire train fleets in a short period of time. Applying condition monitoring to railways is challenging, as equipment is subject to high-intensity shock and vibration. Getting the industry to accept this technology “very much hinges on a product that would satisfy the need in railways for ruggedness plus ease of installation and use. Shoehorning a pre-existing product into the railway application is simply not an option.”

Maintenance Challenge

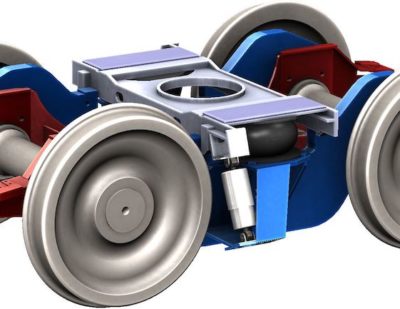

For SKF, the opportunity to try out its condition monitoring system for the first time in the UK came with GTR’s need to overcome issues with its most diverse and performance-enhancing fleet. The fleet is the backbone of train transport in the south-east of England, with a large number of units operating in the third rail environment every day.

“GTR have used bearing riders for many years to mitigate bearing failures, yet despite these actions GTR experienced a number of critical events, which resulted in a unit being out of service for a few months for repair.”

Fortunately, in 2017 GTR was in the early stages of trialling SKF Insight sensors in the field.

Daniele Santomassimo, a business engineer at SKF who worked closely with GTR on installing the condition monitoring, says, “GTR is well known in the UK as a forward-looking train operator that is keen to invest in technology to ultimately improve their fleet performance and reliability.”

Overcoming the Challenges of the Third Rail

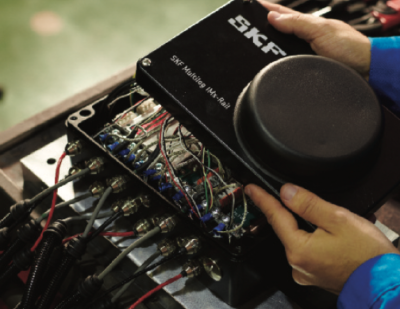

Installing SKF Insight Rail on GTR’s trains was particularly challenging as London’s overground railway network uses a third rail to pick up power. Consequently, this creates an aggressive electromagnetic environment in which the sensors used in the system have to function. Both companies worked together closely to produce a successful working solution.

“We did not anticipate the effect the third rail would have on the operation of our sensors. The magnetic field associated with the third rail was triggering the sensors’ magnetic activation switches. As the sensor is battery powered, communication attempts are intentionally kept to a minimum. However, this magnetic interference was forcing all sensors to communicate with the server, which in turn was draining their batteries. Within a short period of time all 32 sensors had failed. It was a disaster.”

However, SKF worked hard to resolve issues and was open about the problem it was encountering. The two companies have worked together for a number of years on bearing fitting and removal and have built up a good relationship. A solution was quickly found, and the magnetic activation was replaced with near field communication (short-range wireless technology) activation. Following the success of the trial, full installation began and more than 1,000 sensors have been fitted.

Reaping the Rewards

Cooper notes, “The benefits are that we can work with these in conjunction with bearing riding, and we have installed sensors on the most critical positions in the fleet, following analysis of recent failure modes. They are easy and quick to install and commission. GTR have 5,536 axle ends on the fleet, so fitting needs to be easy. Once a rider picks up the bearing as defective, we fit the SKF Insight sensors to that bogie, and that gives us a level of assurance that we can keep running that unit. Once SKF have identified which of the four wheelsets is at fault, we can proactively bring the unit in without impacting on the availability of the fleet.”

Santomassimo points out other advantages in adopting condition monitoring, including the possibility of understanding the types of defects on the bearings. “When the failure modes are clear, it is possible to develop design changes related to the application to increase the reliability of the train wheelset,” he says. “Electric current passage is one of the dominant defects observed and a well-known phenomenon in the industry.”

In the short term, savings will be concentrated primarily on improvements to orders of material and a reduction in unplanned maintenance activities. Long term, the customer will be able to support a condition-based maintenance programme to minimize the operating costs of the trains.

“The most important part of the savings, in my view, is the opportunity of continuously monitoring a key asset of the fleet to eliminate unplanned stops and increase the availability of the trains.”

The Future

GTR is investigating fitting the SKF Insight condition monitoring solution to another of its fleets. “The third rail environment is tough on bearings,” Cooper says. “As an industry I think we need to not only get better at monitoring bearings so we pick them up before catastrophic failure, but also come up with solutions to improve bearing life.”

Santomassimo adds that in the current climate of COVID-19, pressure has increased on operators in the UK to deliver a reliable, punctual and cost-effective service for all their fleets. “The railway market is facing new and important challenges that SKF is ready to support,” he says.

This article was originally published by SKF.