Reliable Rail around the World

Railway Condition Monitoring Technology and Condition-Based Maintenance

Improve fleet efficiency and reliability with innovative railway solutions and services from SKF. Discover how new railway condition monitoring technology and condition-based maintenance can help you extend maintenance intervals. Our railway specific products and services help you obtain lower life cycle costs by letting you use bearings to their full potential.

Condition-Based Maintenance

Time- and mileage-based maintenance remain the most common methods of inspection and repair of rolling stock. This means critical components are maintained based on distances travelled, regardless of their level of deterioration. These approaches are, however, time-consuming and fail to secure that operators can make better use of their components’ potential service life.

Our condition monitoring solutions provide real-time updates of the condition of your bearings and other components. This way, you can avoid taking bearings out of service too early, and instead removing them only when necessary. Through advanced diagnostics, you can access early warnings about any deterioration in bearing condition. In turn, you have sufficient time to plan maintenance before failures can occur.

Extend maintenance intervals, prolong service life and save costs through improved inventory management using proactive, cost-efficient approaches.

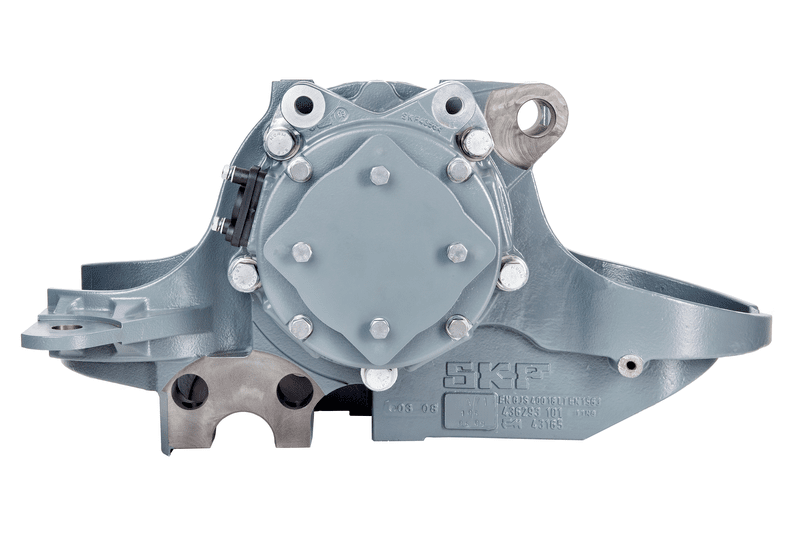

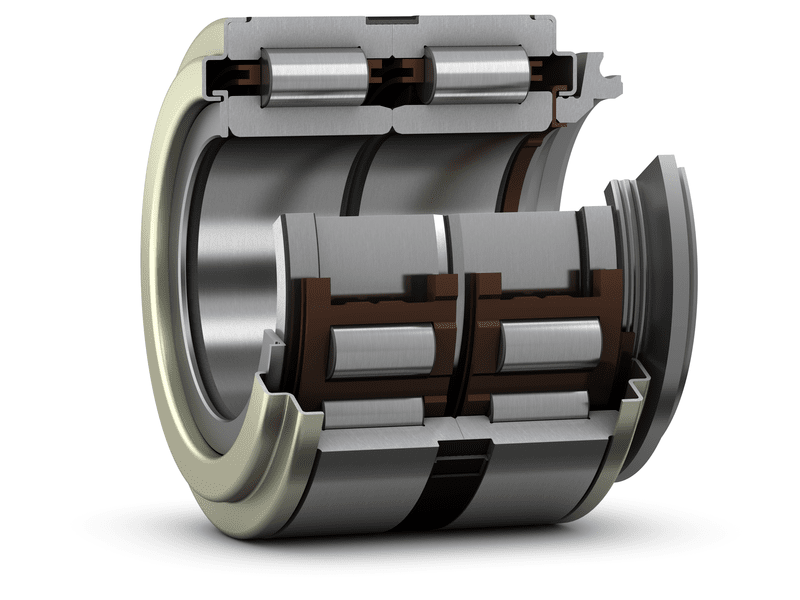

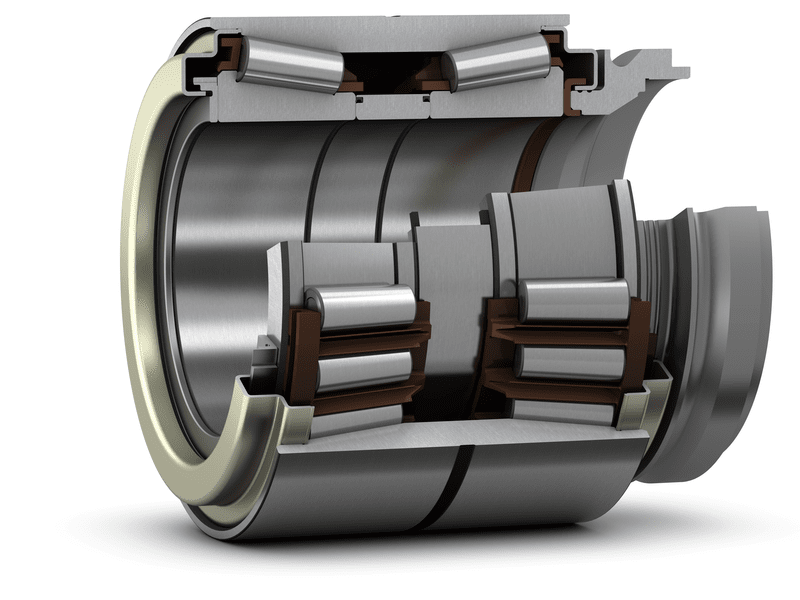

Bogies and Wheelsets

Bogies are complex railway vehicle subsystems, containing brake systems, drive systems, wheelset subsystems and bogie frames with a secondary spring system. Although different bogie designs are applied for different purposes, these serve the same function. This includes supporting the rail vehicle body, helping to ensure stability on track and providing ride comfort. Directly connected to the wheelset and bogie frame is the axlebox, containing the axlebox bearing system, which is connected to further subsystems and components.

Depending on railway gauge, wheel diameter and axleload, wheelsets can have different arrangements and designs. As all of these systems are critical for railway vehicle performance and reliability, careful consideration during the selection of a solution is critical. At SKF, we offer several solutions designed to help ensure reliable and cost-efficient operations. Discover the most suitable one for you.

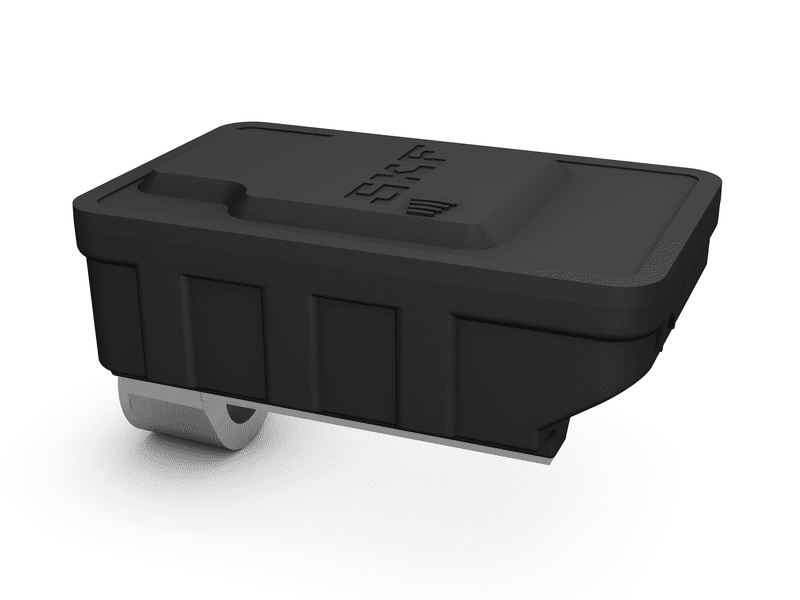

Condition Monitoring for Rail

Reaching goals of increased maintenance intervals requires a transition from time-based to condition-based maintenance. This proactive approach helps to ensure vehicles are only taken out of service when necessary – saving you both time and money.

Using our technical knowledge and diagnostic expertise, we can help you in this transition. Our condition monitoring solutions for bogies use condition detection systems and sophisticated data processing algorithms to detect, analyze and warn you about incipient damage. This gives you sufficient time to plan maintenance stops before significant mechanical failures can develop, increasing the reliability of operations. In turn, you can enjoy reduced maintenance and life cycle costs, as well as total cost of ownership.

Axleboxes

The need for shorter lead times and improved risk management calls for increasingly reliable railway solutions. As the linking design element between the rotating wheelset and the quasi-static frame of the bogie, axleboxes play a vital role in the reliability of rolling stock. With a considerable influence on reliability and economics on track, superior axlebox solutions are required.

We have a global axlebox sourcing and support network, offering design and engineering support throughout the whole life cycle, including customization combined with proven design concepts. Our packages typically include axleboxes, factory lubricated and sealed, ready to mount wheelset bearing units, sensors and monitoring systems.

With the help of our solutions, you can meet performance demands without increased operational risks. And thanks to increased reliability, you are sure to enjoy reduced life cycle and maintenance costs.

Drive System Bearings

Drive systems such as gearboxes and traction motors for trains must be powerful, sustainable, cost-effective and require minimal maintenance. These requirements are steadily getting more important because of increasingly long maintenance intervals and developments in weight of railway vehicles.

Traction motors must deliver high speeds and handle shock loads, but also resist low load conditions for example in coasting or cruise control mode. Additionally, sensitivity towards electrical discharge contributes to unique design challenges in traction motor bearings.

Gearbox design requirements also place high demands on gearbox bearings and bearing arrangements. Specific challenges include wide operating temperature ranges, high shock loads, and increasing loads overall in combination with the drive to reduce friction within the gearbox and lower energy consumption.

We cooperate with customers and operators to implement the latest requirements, and to innovate and deliver high quality products and services. We have long experience with bearing designs for railway drives. Our drive system bearings are designed to cope with high levels of contamination and perform in humid environments, as well as in conditions with variations in speed, temperature, load, vibration, and shocks. Beside developing new innovative solutions, we also offer a preferred range of commonly used bearings and bearing units with good field experience, as well as references for drive systems to make it easier to choose the right products in the design phase.

Lubrication Solutions for Rail Applications

Thousands of trains around the world operate more reliably and efficiently because of SKF and Lincoln automatic lubrication systems. By delivering precise amounts of lubricant directly to the wheel/rail interface, automatic lubrication systems provide significant benefits in terms of wear, energy and noise reduction.

Rail wear has been a challenge for many years in areas of tight curves or heavy loaded tracks. Additionally, in dry weather, the so-called curve screeching or squealing can occur.

SKF EasyRail on-board systems for wheel flange lubrication and top-of-rail conditioning usually are mounted on the first leading vehicle axle. On-board lubrication systems have proven to be very flexible and effective for railway operators due to their variable setting options.

Wayside lubrication systems effectively apply a consistent and controlled volume of lubricant to the rail. The systems hold that grease or friction modifier in place, allowing the wheels to grab and carry it around the track curve. The product range includes solutions for gauge face, top-of-rail and restraining rail.

High-viscous lubricants and friction modifiers that are applied automatically and independently from each other help achieve the desired reduction of noise and wear.

Services

From providing design expertise and advanced wheelset bearings, to installing lubrication systems, validating safety requirements, mounting bearings and more – we offer various railway solutions worldwide. This includes our core competence in wheelset and drive system bearing design, as well as a global network of production, service and remanufacturing centres. Supported by a vast network of sales, application and service engineers, we help to increase railway vehicle safety, reliability, efficiency and extend service intervals.

We can also offer insights into the operation of railway vehicle bogie systems. To do this, we draw on a combination of bearing design and manufacturing expertise, as well as cutting-edge condition monitoring and application knowledge. By collecting and analyzing data throughout the operational life of the train, we help to enhance the next generation of railway designs in ways not previously possible.

SKF solutions for rail provide:

- Reduced total cost of ownership (TCO)

- Reduced maintenance costs

- Longer maintenance intervals and service life

- Increased operational safety and reliability

- Increased energy efficiency