SKF to Supply Railway Wheelset Bearings to Morocco’s National Operator

SKF has won a three-year contract to supply railway wheelset bearings to the Moroccan national rail operator, Office Nationale des Chemins de Fer du Maroc (ONCF)

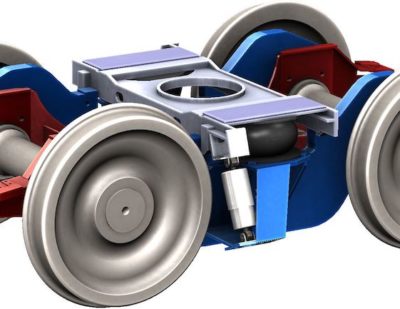

The Moroccan rail operator, ONCF has placed an order with SKF for the delivery of 15,000 railway wheelset bearings over a period of three years for both passenger and freight rolling stock. SKF was chosen because it was the only supplier who could meet the client’s strict technical specifications while being in a position to deliver ready-certified railway bearings on a lead time of just three months.

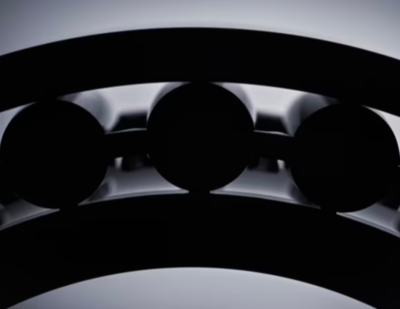

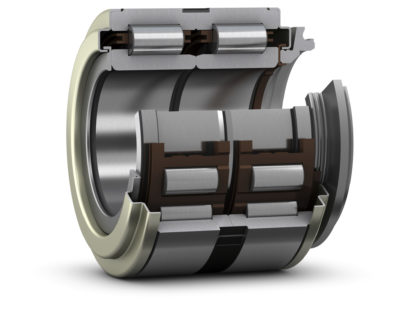

Wheelset Bearings

The units being delivered to ONCF include SKF’s spherical roller bearings (SRBs) which are typically applied as sets of two double-row bearings in a configuration where the two rows of rollers share a common spherically profiled raceway in the outer ring and the two inner raceways are inclined at an angle to the bearing axis. Single spherical roller bearings are also deployed in axleboxes to gain greater design flexibility. In both cases, these bearing configurations are highly tolerant of misalignment and shaft deflection.

Railway Certified

SKF railway certified SRBs have a higher load carrying capacity compared with that of competing products, which is of particular benefit to heavy freight carrying rolling stock applications. Moreover, the new cage design of these bearings ensures higher reliability and longer service life, as well as greater tolerance of the high temperatures and harsh climatic conditions that are typical on this continent.

Africa’s Rail Development

Rail development across Africa is gathering pace; in 2015, ONCF became the first rail operator in Africa to take delivery of high-speed trainsets, which will be deployed on its Tanger-Casablanca line.

Mahdi Sebti, the Paris based Managing Director of SKF’s North African operations said:

“SKF has longstanding experience of railway engineering and the company’s bearings are in use throughout the world, delivering high reliability and long service life under all operating conditions. This new contract with ONCF demonstrates our ability to meet the toughest of specifications while also being ready to react to an exceptionally tight deadline.”

Original article © SKF.

FOR ALL THE LATEST INFORMATION, NEWS, IMAGES, VIDEOS AND DOCUMENTS FROM SKF, PLEASE CLICK HERE.