The New Generation of Live Tracking

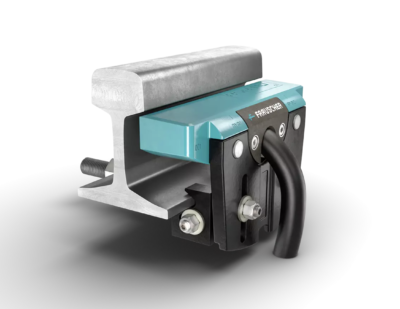

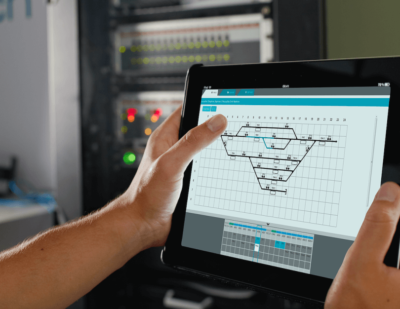

Frauscher makes it simpler for system integrators and railway operators to obtain the information they need to run, monitor and protect their operational network. Best-in-class wheel detection systems, axle counters and tracking solutions based on inductive sensor technology and distributed acoustic sensing form an essential component of a wide range of applications. Frauscher experts are on-site in global markets to ensure comprehensive support during the whole customer life cycle. Additionally, customers are able to design, configure, install, adapt and maintain all components and systems by themselves with the help of individual training and support.

Experience the new generation of live tracking below!

Developing a Revolution

During the last years Frauscher has conducted in-depth research into fibre sensing technologies and their viability within the railway industry. The study revealed that Distributed Acoustic Sensing (DAS) exhibits by far the highest potential for railway market application. As a result, Frauscher has developed the DAS technology in concert with its axle counting and wheel detection systems into a suite of operational and approved products called Frauscher Tracking Solutions FTS.

On the DAS principle the new Frauscher Tracking Solutions FTS can be operated using only one single core of a fibre optic cable. As most operators already have installed such cables next to their tracks for communication, implementation of this new system is simple and quick. By sending laser pulses from an optical unit into the fibre 2,500 times a second, the fibre is transformed into a whole sensor that works like a virtual microphone. Sound waves hitting the cable cause minimal changes in its structure. This leads to a change in the laser pulse’s reflection, which can be measured and set in relation to the time that has passed since sending out the pulse.

A Wide Range of Possibilities Ahead

This enables a wide range of possibilities to improve existing, or create new applications for, train tracking, asset condition monitoring and security requirements. It is possible to detect passing trains, wheel flats, rail breaks, footsteps on or near the cable, works such as sawing or digging, rock falls, animal herds and more – all along the track and in real-time.

In terms of being used within the railway industry, DAS based solutions for sure are still at an early stage. Nevertheless, DAS has the potential to become the basis technology in the railway industry. In the long term it will provide operators with new possibilities to reduce expenses in terms of human and financial resources by contributing to maximise the efficiency of railway operations.