A very special anniversary is to be celebrated this year at the Frauscher India locations in Bengaluru, Mysuru, Mumbai, Kolkata and in Gurgaon: The success story of Frauscher India and its journey to becoming a market leader in wheel sensors and axle counters started exactly 10 years ago with the opening of the corporate office located in Bengaluru.

Since then, much has happened: A local production site has been established in Mysuru in 2014, the local workforce has been growing to more than 120 employees and Frauscher India has been involved in some of the most significant railway projects in the country including Indian Railways and metro corporations. Furthermore, our business has been steadily growing over the last years not just in India, but also overall in Southeast Asia.

To gain further insights on the development of the Indian railway industry, the growth of Frauscher India as well as the challenges and opportunities we are facing in the upcoming years, read the full interview below with Akhilesh Yadav, Managing Director of Frauscher India.

Q: Frauscher India has gained a strong foothold in the Indian railway market. What are some of the achievements that you are especially proud of?

Akhilesh Yadav (AY): The Indian railway market is going through a significant infrastructure modernisation and development phase for many years now and we are very proud that we have been part of some of the most prestigious projects in the country, including dedicated freight corridors, new metro systems, rapid rail transit systems as well as Indian Railways main lines. Due to this, we have been able to contribute to the development of safe, efficient, and modern rail transport systems in India. Railway operators and system integrators rely on our solutions and services to solve their complex problems and deliver their projects to the required time and quality demands. This in turn has led to a great level of trust our customers place in us.

Q: How can Indian railway operators and system integrators benefit the most from our solutions?

AY: One of our biggest strengths is that we primarily focus on solving the customers’ problems and not just on selling our products. Thanks to our collaborative approach, we fully understand the needs of our customers. While railway operators are looking for safe, reliable, and state-of-the-art solutions requiring low maintenance, the integrators are focusing on delivering the project in time with as little integration challenges as possible and smooth commissioning of new systems into operations. With our solutions we meet all those requirements, offering numerous key benefits which our customers highly appreciate such as:

- Our solutions are proven to be safe and reliable systems in more than 100 countries worldwide and in all types of rail applications where they are exposed to the most diverse environmental influences.

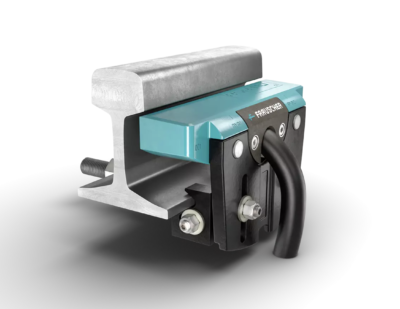

- Our different product features such as drill-free mounting of wheel sensors save both time and manpower during the initial installation but also during track maintenance works.

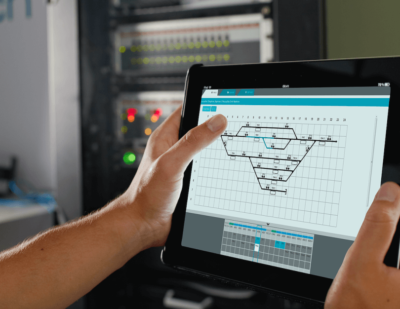

- Our systems do not require any trackside active electronics and most of the electrical measurements and adjustments are carried out from indoor systems. This reduces the need of maintenance work on the track and contributes to the safety of maintenance staff.

Thanks to these features, installation, testing and commissioning of our solutions becomes hassle free. Furthermore, Frauscher introduced many new innovations to the Indian railway industry and is thus setting new benchmarks for the competition to aspire to. Some of those features are the already mentioned, such as drill-free installation of wheel sensors, counting head control, virtual supervisory track sections, built in automatic resetting within redundant systems as well as serial interfaces.

Q: Which are the most noteworthy projects Frauscher India has been involved in the last 10 years?

AY: In the span of only 10 years, we have been able to make our axle counting solutions quite popular in India, thereby contributing to some of the most iconic projects shaping the future of Indian rail transport systems. Frauscher India introduced serial interfaces between axle counter and interlocking in both DFCC projects – Eastern Dedicated Freight Corridor (EDFC) and Western Dedicated Freight Corridor (WDFC), which is drastically reducing multiple components and associated power supplies as well as maintenance requirements. Furthermore, we have been part of most CBTC metro projects including Delhi, Noida, Lucknow, Kolkata, Mumbai, Pune, Kochi, and Ahmedabad. Currently, we are getting ready for the commissioning of the first semi high speed intercity RRTS system in India where we are putting redundant systems to ensure great availability. The modern railway industry needs innovative and reliable solutions and Frauscher is always on the forefront of the latest developments to fulfil the demands of the customers.

Q: How do you see the future of the Indian railway industry and what will be the main challenges and opportunities for Frauscher in India?

AY: The rail industry in India is rapidly growing due to the renewed focus of the government on reducing costs of logistics as well as carbon emissions for the whole transport sector. Thus, large investment projects are planned for new lines, metros, rolling stocks, locomotives, modern stations, as well as signalling systems. There is no better time to be present in the Indian railway industry than now. However, one of the main challenges will be how the different industry players can collaborate and form productive alliances to deliver these mammoth projects.

Q: What are your plans and objectives for the future of Frauscher India?

AY: Our focus is meeting the needs of our customers in the best possible way with our tailored solutions and services – and this will be also one of our main objectives in the future. However, we strongly believe that this can only be achieved with a competent, agile, motivated, and dedicated team on-site. Thus, we will be also focusing on developing the skills and competences of our team further to make sure we work in an efficient and safe way. We also strongly believe in the “Make in India” initiative with a clear vision of manufacturing 100% of our main products directly in our production site in Mysuru, thereby bringing world class technology to India with which we can actively shape the future of Indian railway. Within the Frauscher organisation it is also planned to expand the local production site, which will generate further employment opportunities at Frauscher India, and we are also planning to open a new office location in Kolkata.

This article was originally published by Frauscher.