Frauscher Pulse – Cost-Efficient Maintenance in Railway Operations

Maintenance in Railway Operations

Maintenance work is essential to ensure smooth railway operations. Continuous maintenance of the railway infrastructure ensures high network utilisation and therefore helps to ensure that travellers arrive at their destination not only safely, but also on time. There are many components to consider here in order to guarantee reliable and smooth railway operations on the different track sections, and this can quickly become time-consuming and costly for the railway operator. Find out why maintenance will soon become even more challenging and how you can prepare for the future today with a customer-focused, long-term solution here.

Challenges for Railway Operators

Operational maintenance work is among the core tasks in railway operations in order to guarantee disruption-free rail transport. However, this brings with it an extremely wide range of challenges. Studies show that roughly 25% of infrastructure costs are due to maintenance and renewals. In turn, around 70–90% of these maintenance costs concern corrective maintenance work; in other words, when the damage and associated costs have already arisen.

At the same time, the demand for alternative and sustainable means of transport is increasing, which is why rail infrastructure will continue to be steadily expanded. As a result, even more resources will be needed for maintenance work in the future.

There Are Also Suitable Solutions for Every Challenge

In summary, railway operators are faced with the challenge of continually expanding the required infrastructure while operating under tight budget constraints. In addition, the expectations of passengers regarding safe and timely rail transport must be taken into account. But there is also good news: using sophisticated service solutions, railway operators can outsource maintenance and therefore save on direct costs.

Cost-Efficient Maintenance by the Manufacturer

Outsourcing operational maintenance work to the manufacturer of the products in use – from wheel sensors and axle counters though to software solutions – brings with it numerous benefits. In addition to optimising disruption-free railway operations, cost-efficiency is also significantly increased.

An extremely wide range of studies demonstrate that railway operators significantly improve the profitability of their services when they focus on their core business and outsource maintenance work. An intelligent service strategy together with an individual service agreement form the basis for success here. According to studies, railway operators can save up to 15% on their maintenance costs using technological analysis concepts.

Key Benefits of Outsourcing Maintenance

- Manufacturers are experts in their product range and as service providers, handle all tasks relating to inspection, maintenance and reporting professionally.

- Outsourcing maintenance work conserves financial, personal and time resources.

- Manufacturers can respond to maintenance tasks at short notice, meaning that railway operators remain flexible at all times.

- Service contracts allow for precise cost planning and protect against unforeseen costs.

- The probability of failure is drastically reduced due to preventive service approaches.

The Solution: Frauscher Pulse – a Complete Package That Gives Railway Operators Peace of Mind

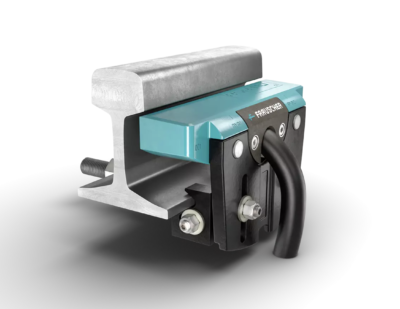

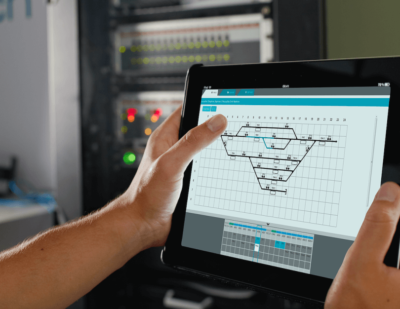

Frauscher Pulse is a sophisticated service concept that comprises operational maintenance work, data-driven services, competence management and tailored customer support. Our offering therefore covers the entire lifecycle of our product range in the field of wheel sensors and axle counting systems.

Frauscher takes care of the correct installation of the wheel sensors and axle counting systems and all the repair work. We also follow a proactive, data-driven service approach, whereby failures can be prevented before they occur. Targeted training and tailored customer support are also offered to you as part of the service package. Frauscher Pulse provides you with a fully comprehensive service solution that ensures safe and smooth railway operations in an efficient manner.

The Benefits of Frauscher Pulse at a Glance

- Professional life-cycle partner for all problems and concerns

- Increased cost-efficiency in railway operations

- On-site support from our Frauscher experts

- Individual service agreements in line with your requirements

- Service throughout the entire lifecycle of our products

This article was originally published by Frauscher Sensor Technology.