Maximum reliability requires guaranteed quality: Frauscher produces inductive sensors, wheel detection systems and axle counters that meet these requirements – and relies on its own in-house specialists to inspect the parts used.

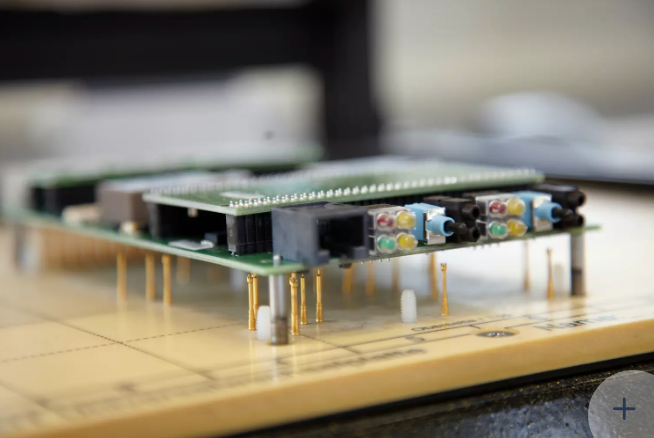

Safety is a top priority in the railway industry. This results in high quality requirements in the development and production of signaling components: All single parts must be thoroughly inspected, their origin and development have to be transparent and traceable. In 2019, Frauscher produced around 30,000 wheel sensors and 74,000 evaluation boards. The test equipment including an own database, which are required against this background, are developed by the company itself.

Diverse Tasks

The Tools department exists since 2013 and today the team comprises seven experts. They all have a sound education in electronics. Various tasks, such as the development of hardware, but also the programming of own software are taken over directly by the Tools team. The core question that is being dealt with here is: How can evaluation boards and sensors be tested efficiently and reliably in the manufacturing process? When working on appropriate equipment, the applicable norms and standards for development and production must always be taken into account. Additionally, testing-procedures and results must be recorded and stored in a database. “This serves transparency,” Florian Maier, manager of the department, explains.

He has been with Frauscher since 2014 and has accompanied the change of his department through the growth of the company. “We have developed various solutions over the years, including an appropriate, complete database. It lists everything that has to do with the testing of components and the test equipment used for this purpose. We can trace exactly which component was tested when and with which device. Since our products are intended for very long-term use, this is of high importance.”

The Automated Way to Digitalisation

Within the scope of the digital supply chain, the department is primarily concerned with the optimisation of processes. “The automation of various aspects can of course only be a first step in this direction,” Florian explains – but it is an important one, as he says: “Many testing-processes consist of numerous individual steps that must be repeated in the same way over and over again. The Advanced Evaluation Board AEB alone, which is used in the Frauscher Advanced Counter FAdC, is subjected to 50 individual measurements. In addition, there are further tests, for example in the temperature test cell. All results are stored in our database. Manual steps would involve numerous sources of error there. We therefore use a lot of know-how to identify potential for automation. We also pass on ideas for the automation of working steps in our production facility. If necessary, we also implement them. The installation of a COBOT was a good example for this lately,” he describes some of the tasks of his department.

Well Networked for Big Plans

Against this background, “networking” is an important buzzword, as Florian explains: “This applies in many respects. On the one hand, we are well networked internally. We work closely with other departments. The Constructions department supports us in terms of setting up mechanical devices. IT ensures that our servers are always online and that our database is accessible at all times. This in turn communicates with various devices and measuring systems. As a high-quality source, it allows the extraction of data records with extremely high information value. In addition, we are in close coordination with our location in India. On the one hand, we provide testing equipment from Austria for local production. On the other hand, they develop their own devices for market-specific products. Thereby we can ensure that all of our products guarantee same quality, no matter where they have been produced.”

Turned the Passenger to a Conductor?

When asked whether building your own test equipment in-house would not be like testing and grading yourself, Florian smiles: “Of course it’s not that simple. The specifications for the respective test equipment are defined very precisely already during the development phase. Critical parts and circuit components are precisely defined right from the start. When working on appropriate testing equipment, we have to strictly adhere to standardized test requirements. Thereby we can guarantee that our test equipment tests what it is supposed to test. This is the only way to ensure that the products we ship will work. This is particularly important in the hardware sector. Unlike software, whose functionality can be validated during development, each hardware assembly must be tested separately.”

However, he clearly identifies one special advantage of in-house test equipment construction: “Flexibility. Many of our products are very special. Purchasing additional testing equipment would massively slow down the entire development and production process. In addition, we can react individually to adjustments. When products are adapted for specific markets, we can quickly adapt the appropriate test procedures and test equipment to accommodate innovations.”