Frauscher India Provides Insights into the Production Site and Its Developments over the Last Years

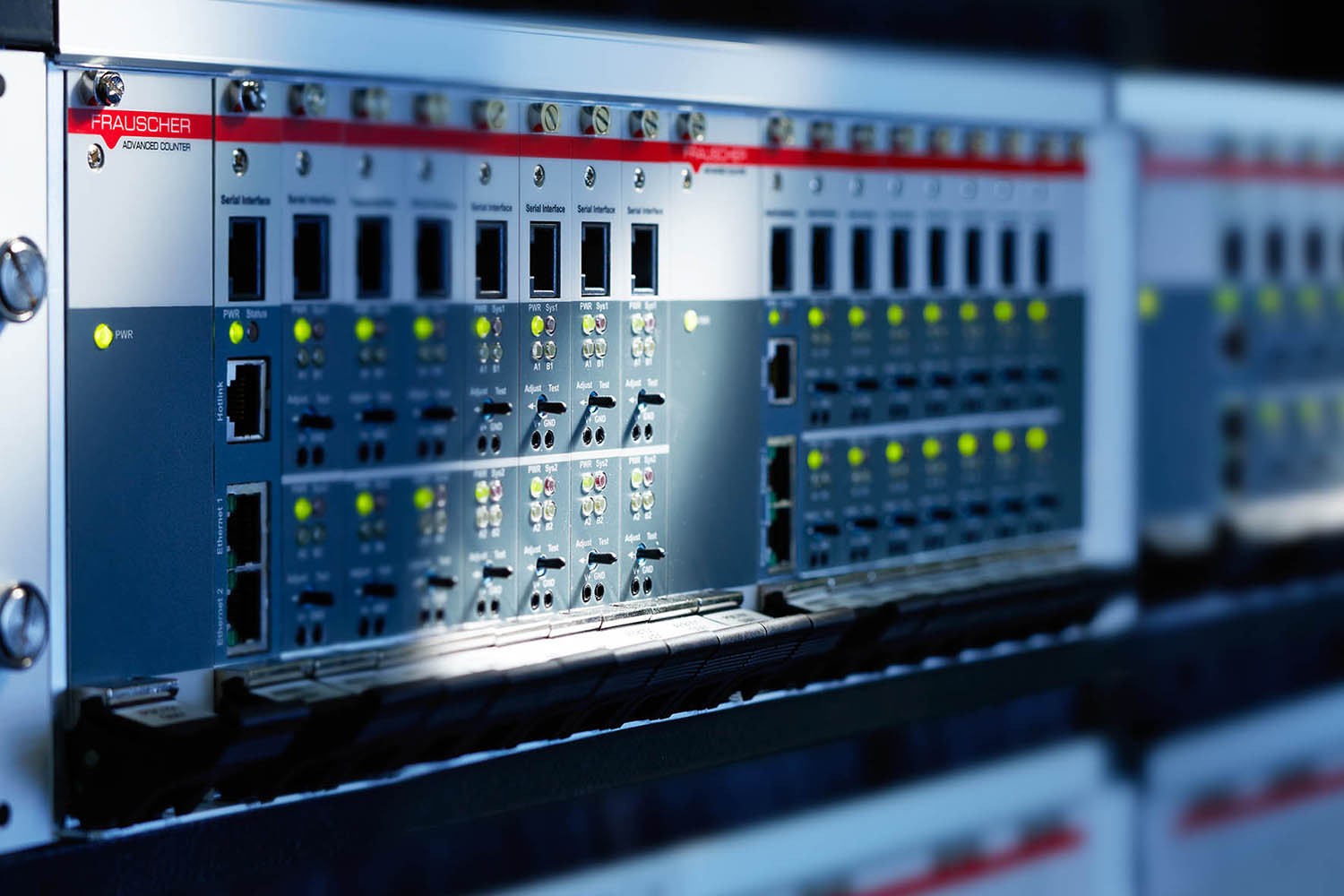

India has one of the largest railway systems in the world with an estimated route length of over 67,956 kms moving 23 million passengers and transporting more than one billion metric tons of freight daily. By 2050, India is projected to account for around 40% of the global share of rail activity. To satisfy the increasing demand for railway solutions, Frauscher entered the railway market in India in 2013 by establishing its local production site in 2014 in Mysuru. Gaurav Kumar Garg, Head of Production at Frauscher India and his team focus on the production of high-quality components of the Frauscher portfolio. The Mysuru production team is also instrumental in setting up processes and infrastructure required for manufacturing, assembly and testing of various products including wheel sensors, electronic boards as well as wired cubicles.

Let’s take a closer look at the customer benefits, the future plans of the productions site at Frauscher India and why so many railway operators and system integrators rely on Frauscher solutions when it comes to wheel sensing and axle counting systems together with Gaurav, who is our expert when it comes to the Frauscher India production site.

What Was Frauscher’s Main Goal of Having Its Own Production Facility in India and What Benefits Does That Provide to Our Customers in India’s Railway Market?

Gaurav: The Indian railway market is going through a significant infrastructure modernization phase over the past few years, with new railway lines being built all over the country and a constant upgrading of existing lines and signalling systems. The main goal of Frauscher for having its own production site in India is to satisfy the current needs and future aspirations of the Indian railway market. Furthermore, it aligns with Frauscher’s philosophy of always staying close to its customers. At the same time, we are also inspired by the “Make in India” initiative of the Indian Government and the indigenization policy of Indian Railways.

The modern production facility in Mysuru enables Frauscher India to produce and test all indoor and outdoor components and to perform required quality checks. With an in-house cubicle assembly and testing area, we can maintain top-notch quality while being able to incorporate last-minute changes if required by a customer. This flexibility allows Frauscher to always deliver its products and solutions on time. It is also worth mentioning that we have a dedicated repair set-up that can troubleshoot and repair any kind of component failures.

Another great benefit for our Indian customers is that they can always visit the Frauscher India production site and gain further insights into the Frauscher products and witness the system performance.

What Are Your Responsibilities as Head of Production at Frauscher India?

Gaurav: As the Head of Production at Frauscher India, I am responsible for the entire production facility at Mysuru. I play the role of an “enabler” who supports his staff to accomplish day-to-day tasks with ease, motivates them to continuously develop and inspires them to achieve more as a team. An inspired employee will do the best for the organisation; right from the generation of innovative ideas, fixing issues, maintaining the production flow, quality and much more, contributing to the success story of Frauscher.

Why Should Indian Railway Operators and System Integrators Put Their Trust in the Products and Solutions of Frauscher India?

Gaurav: To answer this question, please let me refer to the quote “Trust is earned when actions meet words”. Indian railway operators and system integrators have placed their trust in Frauscher since its inception and helped us to become the market leader for axle counting in India. But why do they trust us so much? This is mainly because Frauscher has always been very transparent and open in communicating with the customers. We do not make any empty promises and always deliver on time. Frauscher has a great technical expertise in the form of an experienced R&D team which is constantly working on product innovations and better solutions for the customers. Frauscher products stand for quality, reliability, and easy installation on site – this makes it the perfect choice for every customer.

Has the Pandemic Affected the Production at Frauscher India?

Gaurav: Of course, the pandemic was an unprecedented challenge for all of us. However, it did not have any widespread impact on the production site of Frauscher India. The production site was only closed during the national lockdown; besides that, we have been able to work with full capacity and fulfil all customer orders. Frauscher has put a lot of measures in place to make sure that all employees could work safely. A bio-bubble was created for the production team to reduce the contacts from the rest of the staff. Moreover, a Frauscher task force has been formed to look after the employees to make sure their physical, emotional and health needs were always satisfied. In short, Frauscher has taken all the measures to ensure continuous production, while making the health of its employees a top priority.

What Are Your Future Plans to Enhance the Production Facility at Frauscher India?

Gaurav: The aim is to transform the production facility into a smart factory within the next three years which is a great opportunity to increase our efficiency and flexibility. This shall be achieved through a digitalisation of the entire manufacturing work instructions, automation of repetitive manual activities as well as an optimisation of the entire operations process. At Frauscher India, we have already started to implement Lean and 5S which has already led to great results. For the future, we continue to focus on indigenization of remaining components to strengthen our supply chain and invest heavily in modern and advanced manufacturing tools and testing equipment to enhance the capabilities of the production site of Frauscher India.

This article was originally published by Frauscher Sensor Technology.