SKF

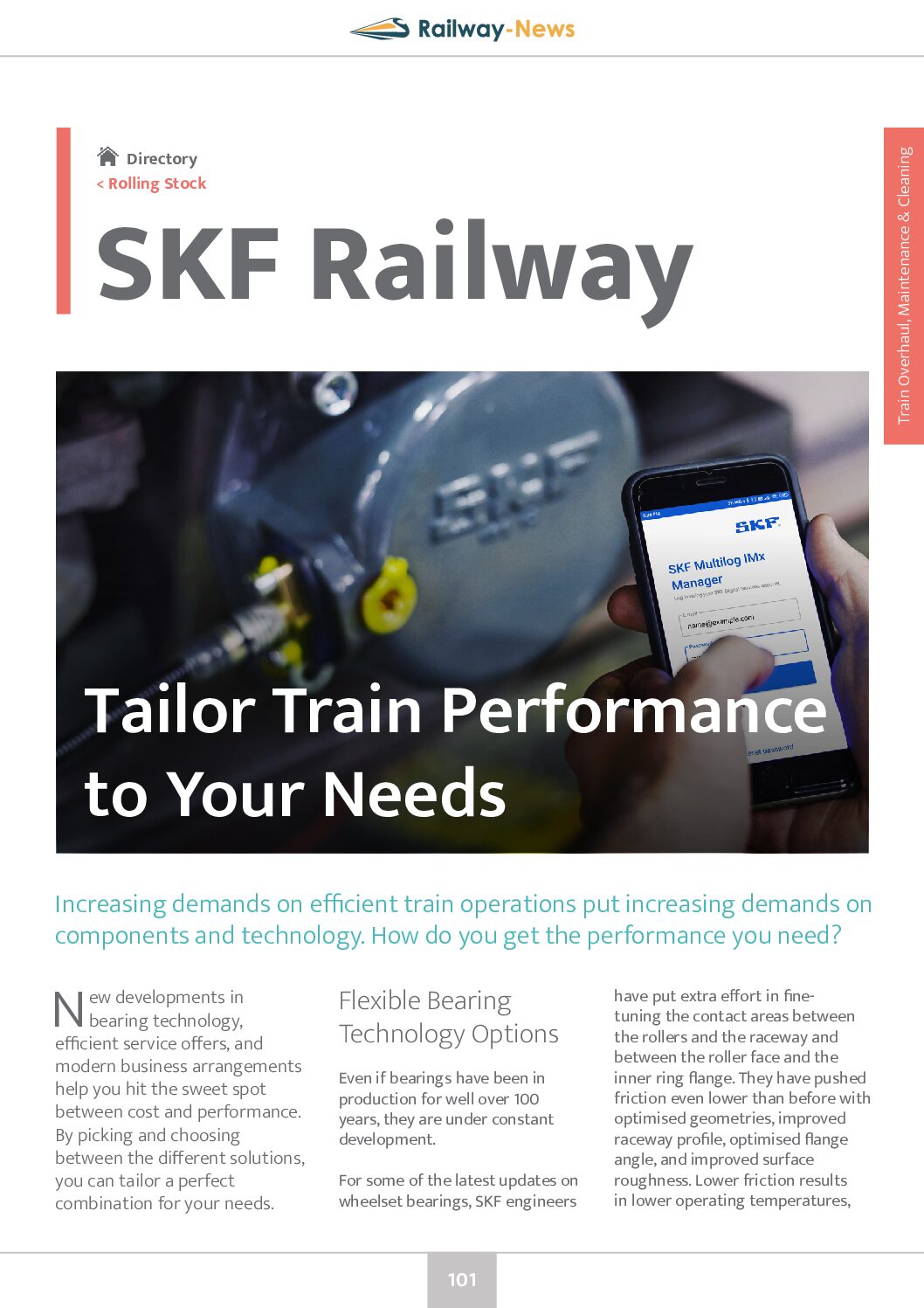

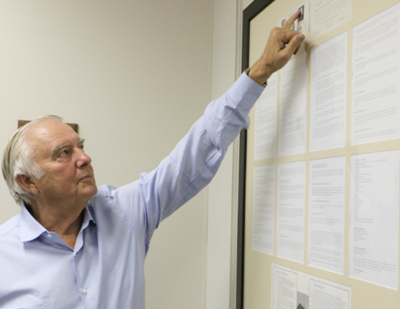

Tailor Train Performance to Your Needs

- This article first appeared in the Railway-News magazine Issue 5 2021.

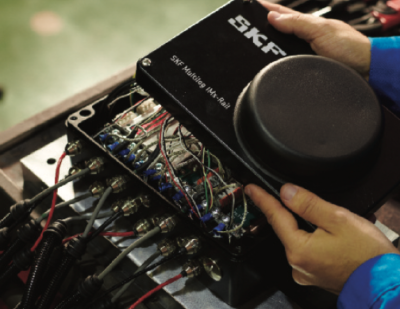

Increasing demands on efficient train operations put increasing demands on components and technology. How do you get the performance you need?

New developments in bearing technology, efficient service offers, and modern business arrangements help you hit the sweet spot between cost and performance. By picking and choosing between the different solutions, you can tailor a perfect combination for your needs.

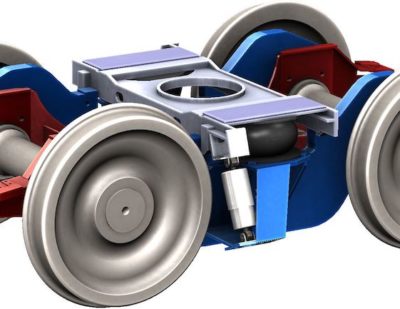

Flexible Bearing Technology Options

Even if bearings have been in production for well over 100 years, they are under constant development.

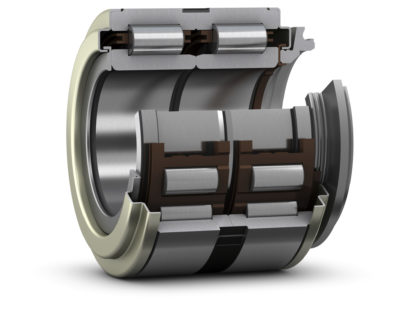

For some of the latest updates on wheelset bearings, SKF engineers have put extra effort in finetuning the contact areas between the rollers and the raceway and between the roller face and the inner ring flange. They have pushed friction even lower than before with optimised geometries, improved raceway profile, optimised flange angle, and improved surface roughness. Lower friction results in lower operating temperatures, which further enhances the preconditions for lubrication.

The bearing material itself is also under constant scrutiny. By refining the case-carburised process during bearing production, SKF has increased material strength and performance to improve train performance.