Embankment & Culvert/Washout Monitoring

If an embankment failure is not managed from an early stage the result could be a derailment. Around the world rail service operators are under pressure to increase capacity, reduce costs and at the same time improve safety. The effects that multiple external factors can have on rail services can be severe. Embankment slips or other earthworks problems can go un-noticed until the worst would happen, a derailment leading to injuries and even fatalities.

Causes for Embankment Failure:

- A defective drain saturating the soil

- Leaning OHLE/signals

- Animal infestation – rabbits or badgers undermining the slope.

- Cracks appearing in the cess or embankment sides and vegetation movement

- Fence line disturbance

- Signal troughing disturbance

- Poor control of mineral extraction works

- A change in the rate of water abstraction i.e. from aquifers – a rise in the water table soaking the soil

- Recent dredging of a canal or dyke alongside the railway

- Tidal watercourses alongside the railway

- Blocked and/or overloaded culverts & washouts can cause track bed deterioration

Solution

Our solution provides an Earthworks Monitoring System utilising intelligent wireless sensors. Our uniquely developed web-based platform is a host for meticulous monitoring data for multiple clients and user accounts. At Yeltech, we have created an intelligent hub for numerous remote monitoring needs using the latest technology and data requirements. The server continuously transmits reliable data from our secure cloud-based environment that is available online and via mobile application. Meaning engineers can have remote access to their equipment in the field, 24/7; removing the need to send engineers to a site.

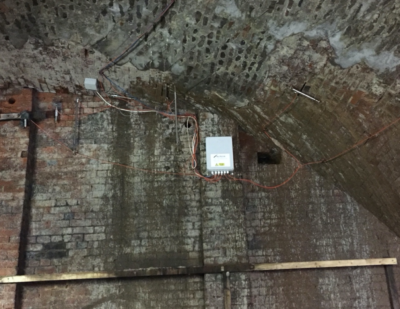

Introducing Our New Embankment & Culvert/Washout Monitoring Devices

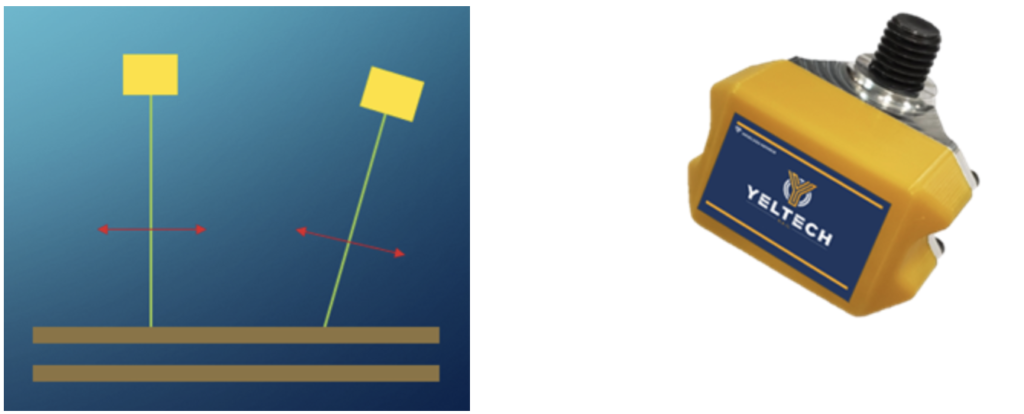

- Embankment monitoring with YEL360 – YEL360 Asset Health Sensor can be used for remote monitoring of embankments in high risk areas using a triaxial tilt sensor.

The YEL360 features smart multisensory capabilities, providing a rich source of data that is communicated with simple alerts, delivered in a package designed to survive harsh fixed or mobile industrial environments. The smart technology connects and sync real time data through our cloud based IoT Platform, via Bluetooth or wireless mesh via a gateway.

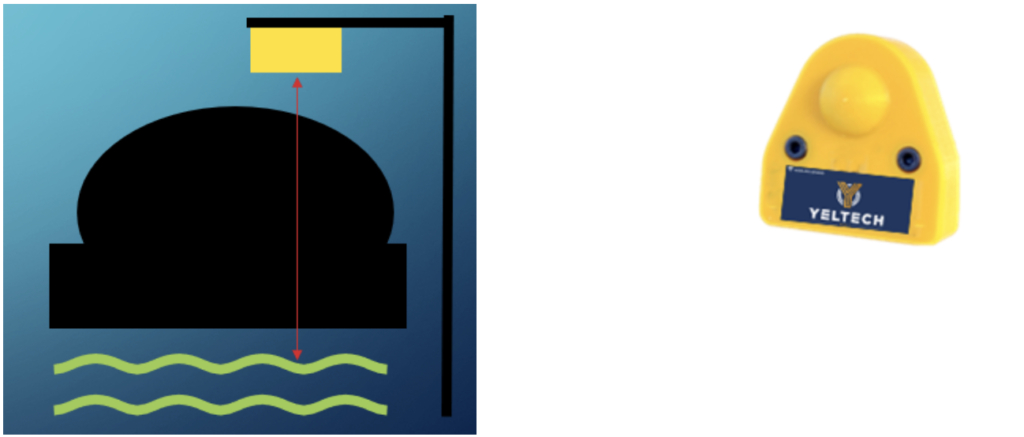

- Culvert & Washout monitoring with PS210 – The intelligent PS210 Position Sensor can be used for remote monitoring of water in high risk areas.

The intelligent PS210 Position Sensor can be used for remote monitoring of water levels in high risk areas. Our robust, accurate, non-contact solution for level or position sensing applications. The smart technology connects and sync real time data through our cloud based IoT Platform, via Bluetooth or wireless mesh through a gateway.

Specifications & Benefits

- Solar-powered data loggers

- Wireless mesh tilt sensor network, LoRaWAN, LTE-CAT-M1 and NB IoT Gateway

- Configurable alerts: email/SMS

- Multi asset management system

- Over 5 years battery life – no mains

- No wires

- Low battery warning

- Minimal maintenance & low cost

Conclusion

Yeltech has successfully developed a solution for Embankment & Culvert/Washout Monitoring by developing two smart monitoring devices (Embankment monitoring with YEL360 and Culvert & Washout monitoring with PS210) which can highly help multiple industries face their challenges.

This article was originally published by Yeltech Ltd.