Pandrol Achieves Environmental Product Declarations for Sustainable Resilient Product Range

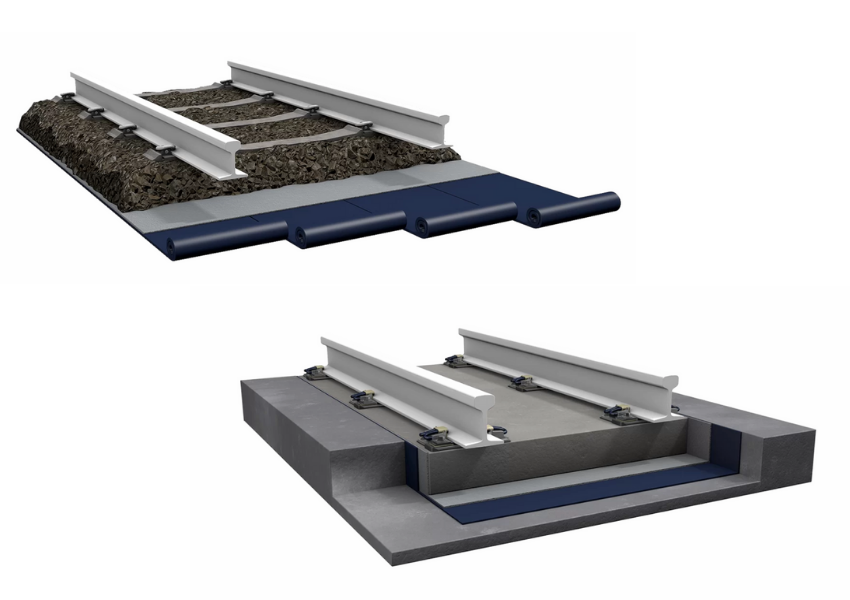

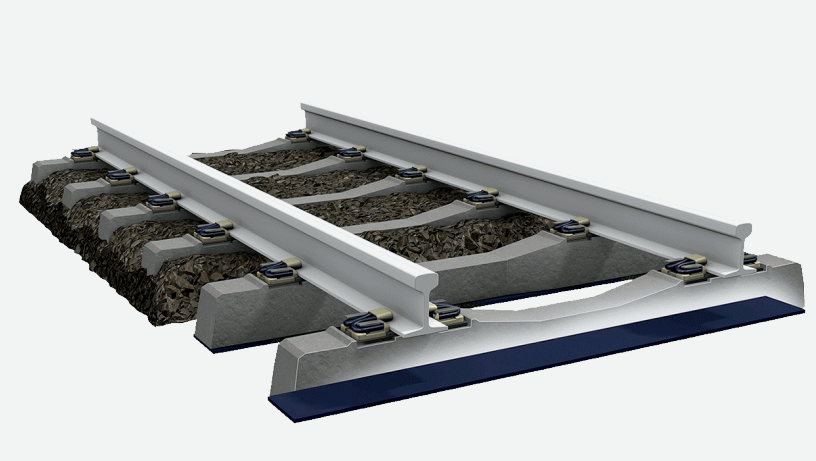

Pandrol is delighted to announce the publication of Environmental Product Declarations (EPDs) for three of its flagship Sustainable Resilient System (SRS) products – the Under Sleeper Pad, Under Ballast Mat and Floating Slab Mat.

Pandrol SRS products repurpose rubber from used tyres to provide resilience to rail infrastructure, mitigating noise and vibration, reducing the need for maintenance and increasing the life of the railway.

The new EPDs are clear evidence of Pandrol’s determination to help reduce the rail industry’s carbon footprint. Registered as part of the International EPD System®, the reports provide transparent, independently verified environmental data for each product, drawing on a detailed assessment spanning raw material supply to delivery to the customer.

Each report concludes with a typical carbon footprint for the product, which will benchmark continuous improvement, as well as offering a measurable metric that rail operators and infrastructure designers can use to support environmentally-friendly product choices.

When the EPD team ran the same scenarios for each product with virgin polyurethane rather than Pandrol recycled rubber, the carbon footprint doubled for the Floating Slab Mat and Under Ballast Mat, and tripled for the Under Sleeper Pad.

“We are delighted with this independently verified recognition of our efforts to create the very best noise and vibration attenuation products on the market.

“Our SRS solutions have all passed the same demanding technical performance tests as alternative products. Now we have confirmation that they also come with exceptional green credentials. The EPDs provide irrefutable evidence that our recycled SRS products are the right choice when it comes to quality, performance and sustainability.”

“It is extremely pleasing to see these results coming out of the EPD process. We use end-of-life tyres for their resilient properties, so to discover there is also a huge environmental benefit to producing our mats this way is a bonus.”

This article was originally published by Pandrol.