ZÖLLNER Signal GmbH

Infrastructure Solutions Both Preventive and Reactive

This article first appeared in the Railway-News magazine, Issue 4 2022 Data & Monitoring edition.

Christian Olsiewski, Product Manager ZÖLLNER Signal GmbH

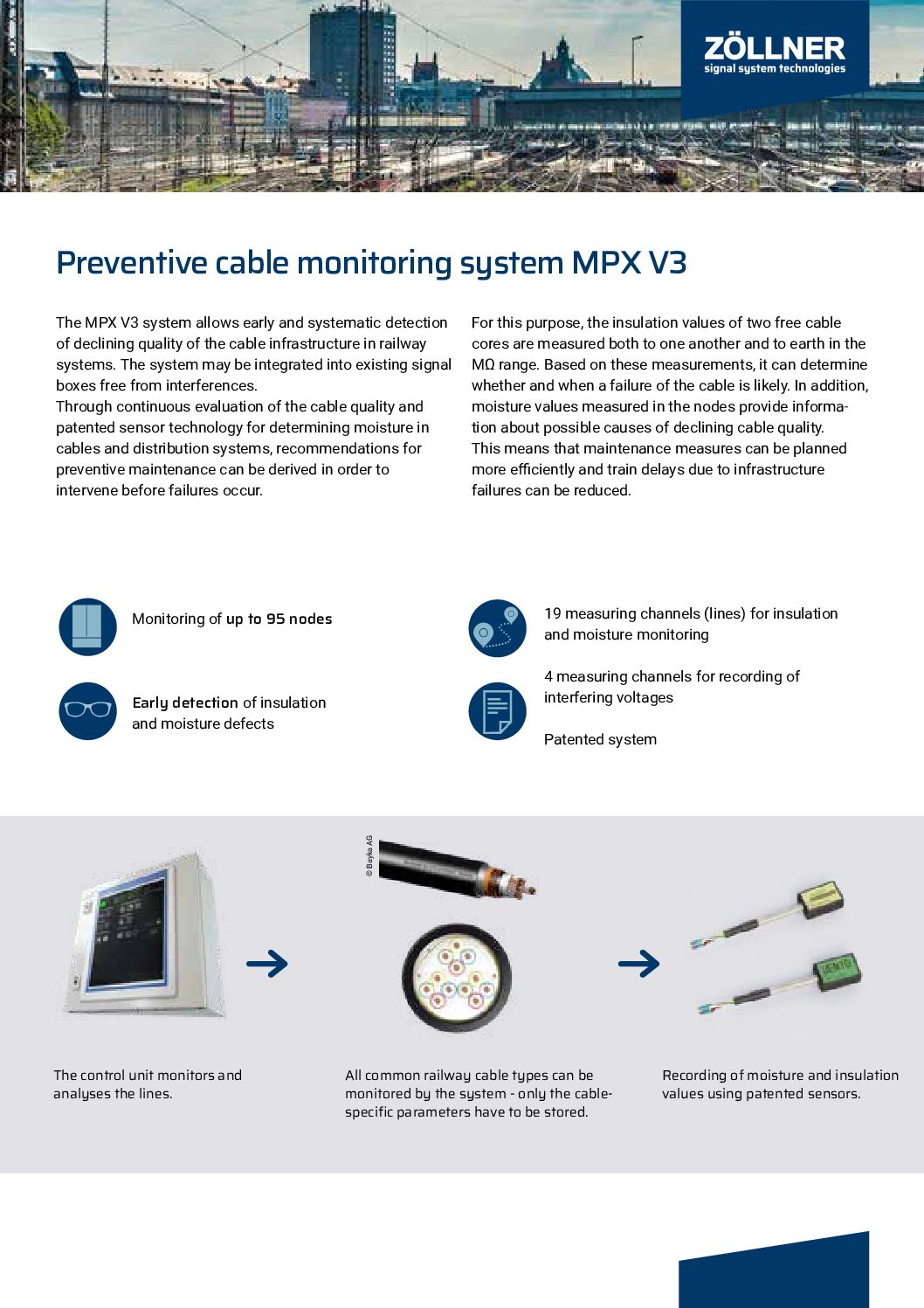

Preventive Cable Monitoring System MPX V3 Reduces Train Delays

The vision of ZÖLLNER’s product line for infrastructure solutions is to significantly contribute to mobility changes – convincing more and more people to use the railway is necessary to tackle climate change. Therefore, we need to make the railway infrastructure more resistant to sudden failures that lead to train delays and in consequence to less public acceptance of the railway. One solution to reach this goal is the preventive cable monitoring system MPX V3 – continuously tracking humidity and insulation values on the cable infrastructure to detect and evaluate quality degradations before they lead to failures.

Brief Introduction to the System

The control unit of the MPX V3 is integrated into signal boxes and can measure insulation values of the outgoing cables themselves as well as humidity values in cable cabinets using data provided by patented passive sensors [Fig. 1].

The MPX system can be configured individually from five up to 19 measuring channels which consist of up to five partial measuring sections each. Values of the interlocking system’s ground fault detector, Bender IRDH265, can also be monitored by the MPX V3. In addition, the system can be extended by four channels recording the interfering voltages acting on the cable. Since the MPX V3 uses two free cable cores for measurements, it is not interfering with the superior system.

The collected data is always available – directly at the touch display of the main unit, remotely via LTE connection or in semi- annual reports of the manufacturer including recommendations when and where to take action.

The system has product approval from Deutsche Bahn, is now installed in more than 10 signal boxes and has already proven itself in practice.