Stäubli Electrical Connectors

Fork Plugs in the Railway Industry: The Invisible Heroes of Connection Technology

This article first appeared in the Railway-News Magazine Issue 1 2024.

In an era of rising fuel costs and growing concerns about climate change, train travel is becoming increasingly popular among travellers.

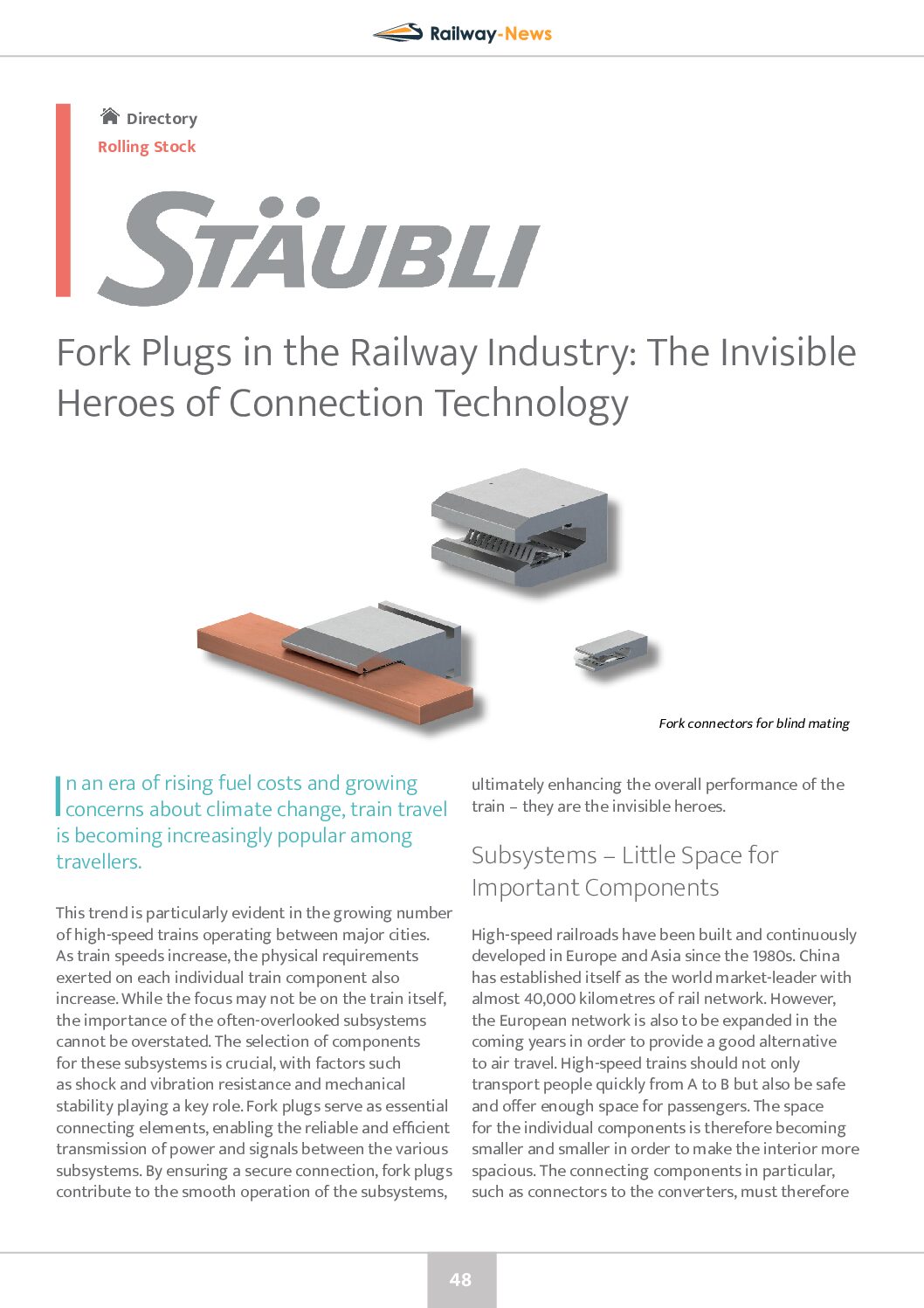

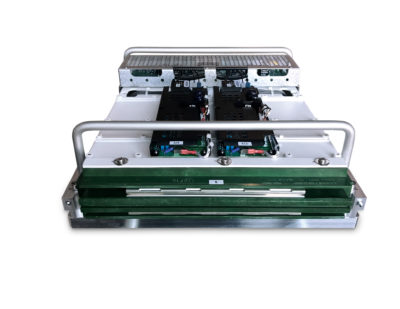

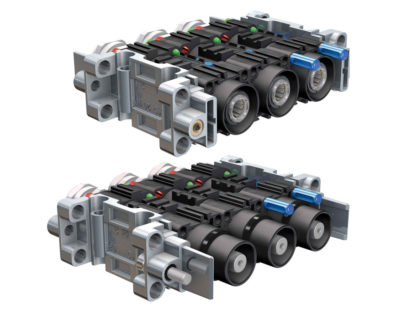

This trend is particularly evident in the growing number of high-speed trains operating between major cities. As train speeds increase, the physical requirements exerted on each individual train component also increase. While the focus may not be on the train itself, the importance of the often-overlooked subsystems cannot be overstated. The selection of components for these subsystems is crucial, with factors such as shock and vibration resistance and mechanical stability playing a key role. Fork plugs serve as essential connecting elements, enabling the reliable and efficient transmission of power and signals between the various subsystems. By ensuring a secure connection, fork plugs contribute to the smooth operation of the subsystems, ultimately enhancing the overall performance of the train – they are the invisible heroes.

Subsystems – Little Space for Important Components

High-speed railroads have been built and continuously developed in Europe and Asia since the 1980s. China has established itself as the world market-leader with almost 40,000 kilometres of rail network. However, the European network is also to be expanded in the coming years in order to provide a good alternative to air travel. High-speed trains should not only transport people quickly from A to B but also be safe and offer enough space for passengers. The space for the individual components is therefore becoming smaller and smaller in order to make the interior more spacious. The connecting components in particular, such as connectors to the converters, must therefore be designed in such a way that they fit into this reduced space. Not only must space be taken into account, so too must ease of installation in order to avoid long downtimes in the event of maintenance. A slide-in blind mating connection is required here. Due to the considerable vibrations and shocks, the connections must have a particularly stable connection and be able to withstand the high electrical currents.