Michel Schmitt, Business Development Manager Railway at Stäubli Electrical Connectors, tells Railway-News about the company, its innovations and expertise and why its products are perfectly suited for rail applications.

Can you give us a glimpse into the history of Stäubli Electrical Connectors?

Stäubli Electrical Connectors is a leading international manufacturer of high-quality electrical connectors and system solutions for industrial applications. Its product portfolio ranges from miniature to high- performance connectors for power transmission, industrial automation, transportation, test and measurement, and many other industries.

In photovoltaics, Stäubli is the global market leader with its MC4 connectors. The core of all Stäubli electrical connectors is the unique MULTILAM contact technology.

We are a part of the Swiss family company Stäubli, a world-leading provider of innovative mechatronics solutions with three specialised areas of activity: connectors, robotics and textiles. The company was founded in 1892.

You’ve been working in the railway technology industry for 30 years, and you’ve contributed to many innovations. Can you tell us a bit about that?

Yes, that’s right. As I mentioned, our connectors are based on the MULTILAM technology. To put it another way: the MULTILAM technology is the core of all of our electrical connector solutions, and provides very high contact quality with minimal power loss. This allows for an exceptionally long service life, making it the essential innovation at Stäubli Electrical Connectors.

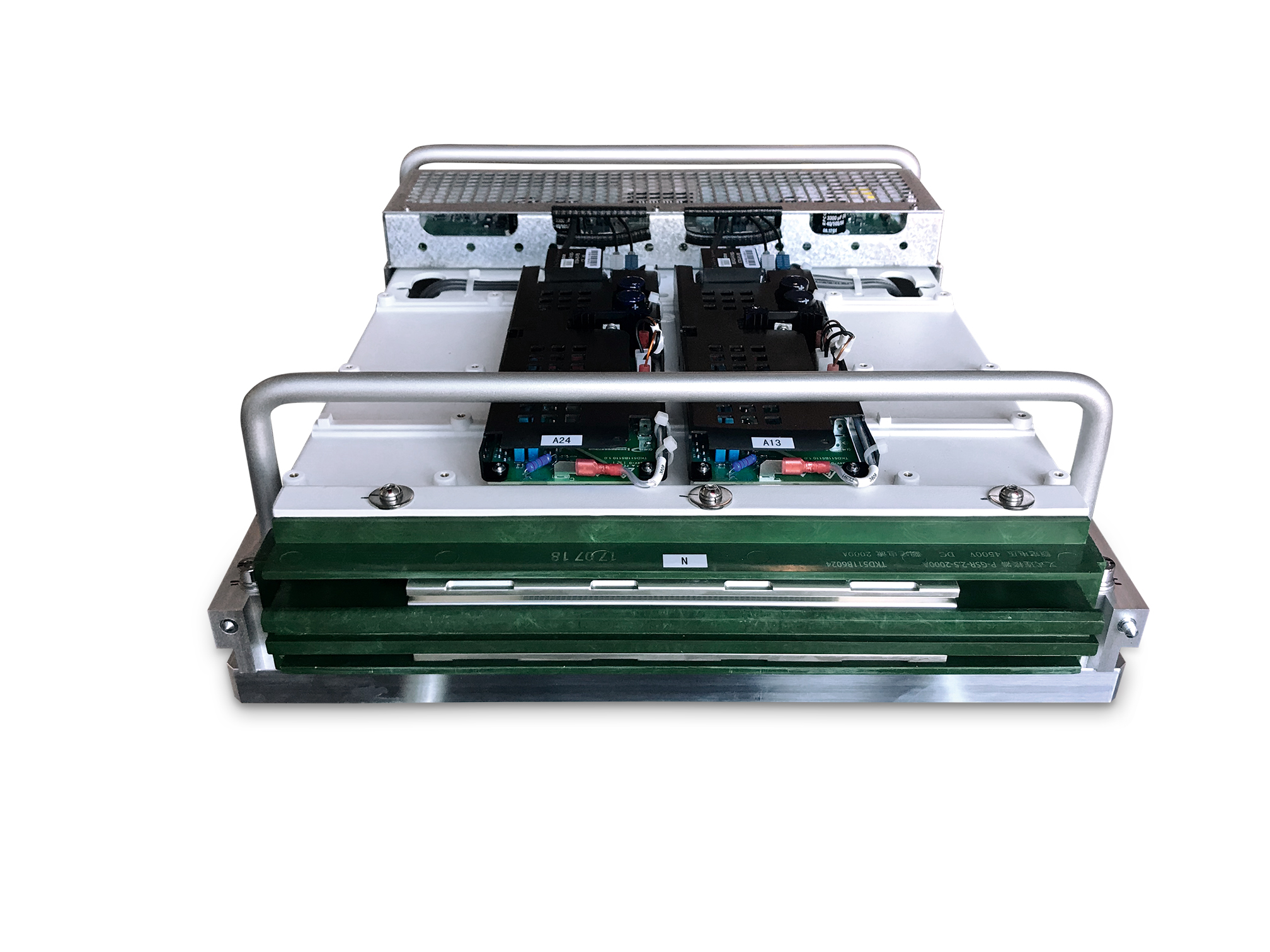

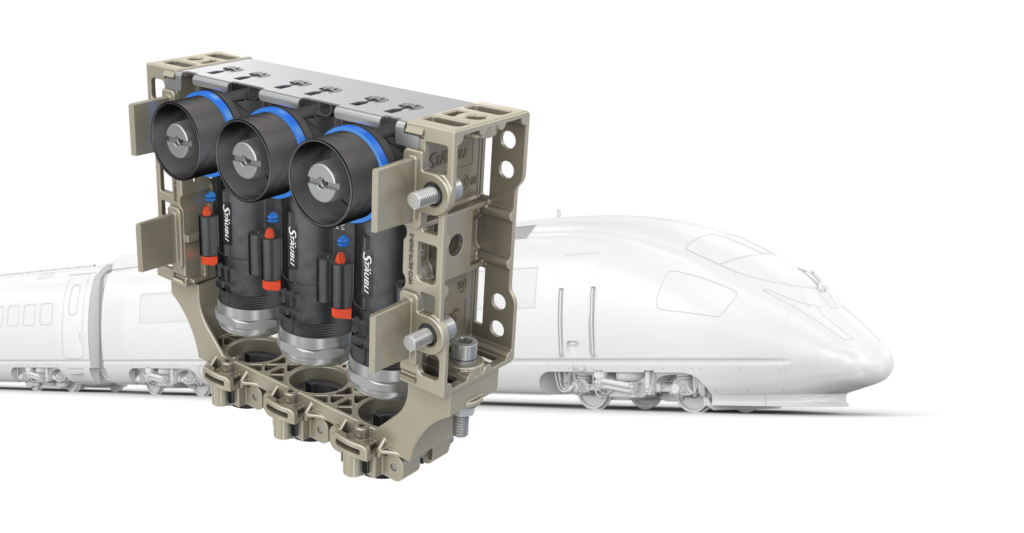

In 2012, we designed the first modular power connector system for high-current connections in a traction chain of a train, and introduced it to the market with great success. Another ground- breaking project was our custom fork-plug system for contacts in high-voltage applications. Working closely with CARS (China Academy of Railway Sciences), we developed a bipolar GSR 2.5 fork plug for the latest generation of Chinese high- speed trains. The GSR connects the water-cooled circuit board, where the IGBT module (insulated-gate bipolar transistor) is mounted, with the busbar in the converter cabinet, and allows for fast assembly and disassembly. Using extremely powerful insulating material, we’re able to meet strict industry requirements for mechanical stability and resistance to aging.

What does quality mean to you?

For us, quality means fully meeting our customers’ requirements and expectations, and offering customised solutions for specific needs. Our electrical connectors are designed for demanding applications with high current- carrying capacity, which makes us a welcome and reliable partner in harsh environments. We provide solutions that are built to last, and that not only ensure our customers’ productivity, but actually increase it.

What expertise does Stäubli offer for rail vehicles and transport solutions?

As an industry partner and major supplier for the international railway sector with over 30 years of experience, we know the challenges and expectations of this market, including continuity of service, extreme weather conditions and mechanical stress. Connection solutions in the rail industry are essential for mobility systems, and for safety as well. We often get involved in customer projects as early as the front-end engineering phase. Thanks to our many years of expertise, we’re able to offer custom advice and solutions that are precisely tailored to the customer’s specifications, independently of the customer’s location and for all types of rail vehicles.

You mentioned safety as an essential concern. How does Stäubli ensure the safety of its solutions? Is this a particular challenge, given the varying climate conditions and different standards in different parts of the world?

Complying with international standards is obviously fundamental for us. As a certified manufacturer, we are proud to satisfy all the requirements and local regulations for each market we serve. We’re actively involved on the relevant standards committees, which allows us to react quickly to changes.

In the field of railway technology, we’re certified ISO/TS 22163, formerly IRIS – the International Railway Industry Standard. It’s a reference system that was created at the initiative of major equipment providers and is maintained by the European rail industry association

UNIFE (Union des Industries Ferroviaires Européennes) as a tool for continuous improvement and excellence in research.

Our products meet or exceed all relevant industry standards. One example: for the fire safety standard EN45545-2, our products are classified at the highest level – that is, we test our products beyond the limits set by the standard. We attach great importance to field data, and in our in-house test labs, we continuously run very strict tests based on customer specifications, as well as endurance tests. Our test labs are regularly audited by international standards organisations around the world, so they’re able to ensure a very high standard of quality.

What’s special about your products in this sector?

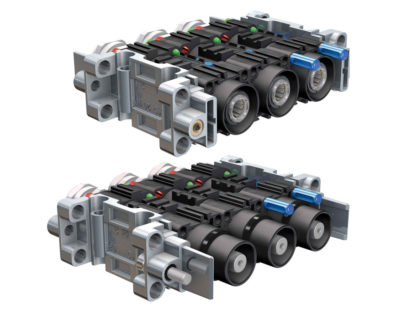

We offer solutions that reduce maintenance and repair times for railway cars and locomotives. Our products are built to provide the very highest level of reliability and are based on modular systems like our Modular Power Connector MPC. The benefits of the MPC system lie in its practicality and user-friendliness: thanks to the modular system, customers can choose from a vast range of multi-pole connector designs. And since the connectors meet all railway industry standards and offer nominal voltage/current values of up to 3600V / 700A, they’re suitable for many different high-current and high-voltage applications. These applications include connections for transformers, traction motors, converters and batteries, and power connections between cars.

In short, our products offer high current-carrying capacity, a compact and space-saving design, and are perfect for use in hard-to- access locations. We specialise in customer-specific solutions, and we see ourselves as a solution provider and partner for innovative, high-performance, lightweight and streamlined solutions specifically for harsh environments.

What trends do you see in the railway sector, and where do you see Stäubli 10 years from now?

As of today, not all railway lines are electrified, and some countries still rely on the use of diesel locomotives. But there’s a strong trend toward alternative electric drive solutions. So we need smart, flexible connection solutions to safely connect with modern systems – like battery systems, for example – and we believe that the trend away from diesel will continue in all major countries and regions in the years to come. Various alternative drive systems are currently under development, including hydrogen, battery-powered systems, and other technologies. For us as a supplier of electrical connectors, it’s an ideal situation. Speed is also a key factor, whether that means reducing downtime with a fast, user-friendly connection process, or in terms of high-speed trains that require connectors with a higher load capacity. So yes, we can confidently say that we’re ready for the market requirements of tomorrow, and in an ideal position for the future with our products and planned innovations.

For more information visit www.staubli.com/electrical.