Missing: 20 Centimetres – Raising Rails for Accessibility

The rails in Israel’s Ra’anana station are about 20 centimetres too low. Three options to raise them.

In Switzerland, we are used to climbing one or more steps between the platform and the train at some stations. Although the Disability Equality Act (DDA) has been a done deal for years, not all stations have been converted by far—much to the chagrin of people in wheelchairs, with prams or luggage.

These stations are relics of times long past. Only since the DDA (and comparable laws in other countries and at EU level) have there been uniform specifications as to how high the platform edge should be in relation to the upper edge of the rails. In Switzerland it is 55 centimetres.

Such a standard is necessary so that rolling stock manufacturers can adjust the height of their running boards and carriage floors to the infrastructure so that passengers entering and leaving the train have to overcome an edge of no more than a few centimetres.

Before the new millennium, this accuracy was not a priority, as most trains had one or more steps in the door area anyway. A gap between the platform and the footboard did not make any difference.

A Modern Phenomenon

For a long time, it was hardly conceivable that passengers would have to climb down a step from the platform to the inside of the carriage. For cost reasons, no railway would have built a platform twice as high. Costs on the part of the train manufacturers also made this problem unrealistic—low-floor carriages are technically complex and no industrial company would think of lowering its carriages as far as possible instead of only as far as necessary.

Therefore, having to descend from the platform into the train is a thoroughly modern phenomenon. It occurs when standards are not in place, when they are not known to all involved or when they are changed during the course of the project.

One of these misunderstandings happened during the construction of Ra’anana South station on Israel’s Sharon line. When the new station opened in 2018, the platforms were about 20 centimetres too high for the low-floor trains that had been procured in the meantime.

This was all the more unattractive because the station is located underground and was therefore equipped with ballastless tracks. Their sleeper blocks have to be aligned to the tenth of a millimetre before they are concreted in place, as the track cannot be tamped into the correct position, unlike the classic ballasted track superstructure.

“Jacking Up” Sleepers?

The state railway Rakkevet Israel (RI) had to make the unpleasant decision whether to accept the situation—ballastless tracks are designed for a service life of about 100 years—or whether to incur the additional costs for an adjustment. RI opted for the more customer-friendly option and commissioned RUBI Railways and Pernstich Engineers with the project, which was unique in its own way.

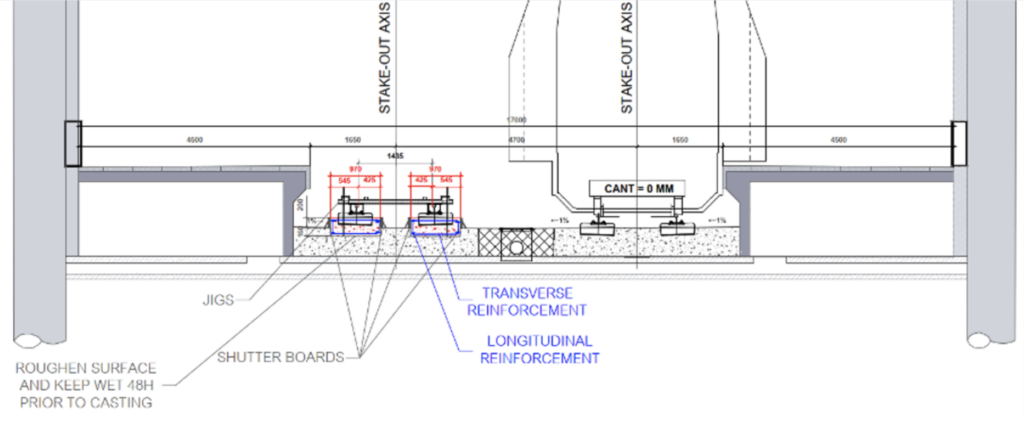

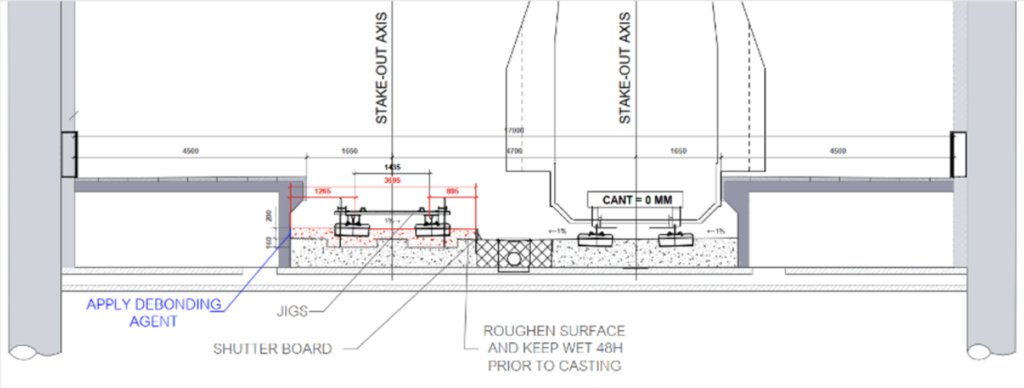

The two partner companies considered various options to make up for the missing 20 centimetres. One possibility is to “jack up” the sleepers and rails and leave the underlying concrete slab at the existing level. The advantage of this solution is that the concrete slab, which is in almost perfect condition, remains basically unchanged. Two troughs would have to be milled out in the longitudinal direction, in which the new concrete beams would then be created.

In this, the major disadvantage of this option becomes immediately apparent: concrete landings with a height and width of around 20 centimetres are not exactly stable. In order to be able to bear the load of the superstructure and the trains running on it, which amounts to several tonnes, the longitudinal beams would have to be reinforced.

In addition, water and waste would accumulate in the resulting trenches, so they would have to be cleaned regularly. If this were to be done by machine, a special construction would probably be necessary, which would be as unique as the problem and its solution.

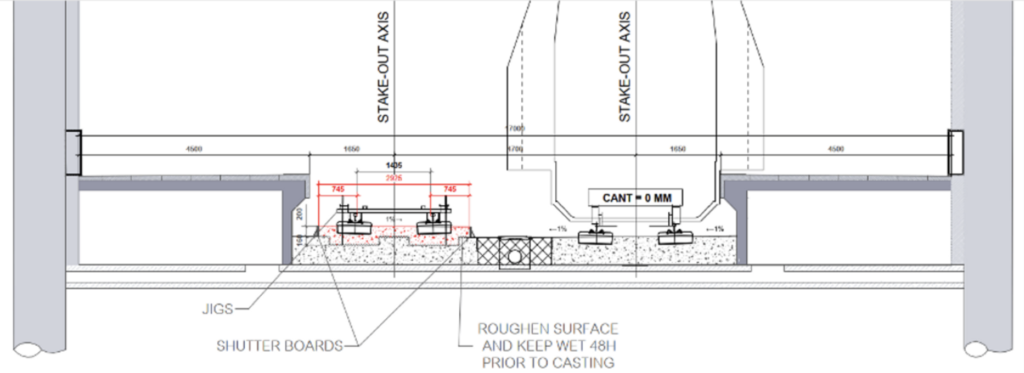

Therefore, RUBI Bahntechnik and Pernstich Ingenieure proposed two options in which the concrete slab is raised essentially across its entire width. This way, the load is distributed and the concrete does not need to be reinforced.

It is conceivable that the raised slab be slightly narrower than the existing one and that its landings slope down into the existing drainage channels. However, this solution does not bring any significant advantages compared to a full-width slab, and costs almost the same. Therefore, RUBI Bahntechnik and Pernstich Engineers recommended to the RI that a new concrete slab be constructed to the same width as the one below.

The second-best option would be the jacking up on longitudinal beams. Apart from the reinforcement, this variant differs from the other two in one essential point: much less concrete would be needed. Therefore, this option becomes more attractive if there are procurement, production or transport bottlenecks. The effects of the war in Ukraine show that such problems can develop quickly.

For Israeli rail passengers, the three variants are practically equivalent. They will all allow step-free boarding and alighting in the future. The construction time for all three options is around 40 days. And finally, the costs, which may have an impact on ticket prices, are about the same.

This article was originally published by RUBI Railtec.