Harsco Rail, the railway track maintenance division of Harsco Corporation, introduced its new TX16 Production and Switch Tamper at Railway Interchange 2019 in Minneapolis.

The TX16 leverages Harsco Rail’s decades of Maintenance of Way expertise into one machine capable of delivering high production and accurate track correction. It is an amalgam of proven features from across the Harsco Rail fleet, all of which combine to improve productivity, operator safety, ergonomics, tamping quality, reliability, and serviceability. These features include the Hybrid Index Tamping Cycle which, in tandem with TX16’s tie-finding technology, offers high production rates regardless of ballast conditions. The TX16 also features switch tamping flexibility through four independent tamping units, which allows for each pair to be deployed separately when working switches. The half-split design also reduces weight. From an environmental standpoint, the increased productivity rate and reduced weight, coupled with the higher-efficiency systems, results in significantly lower fuel consumption per mile of tamped track and a reduced carbon footprint.

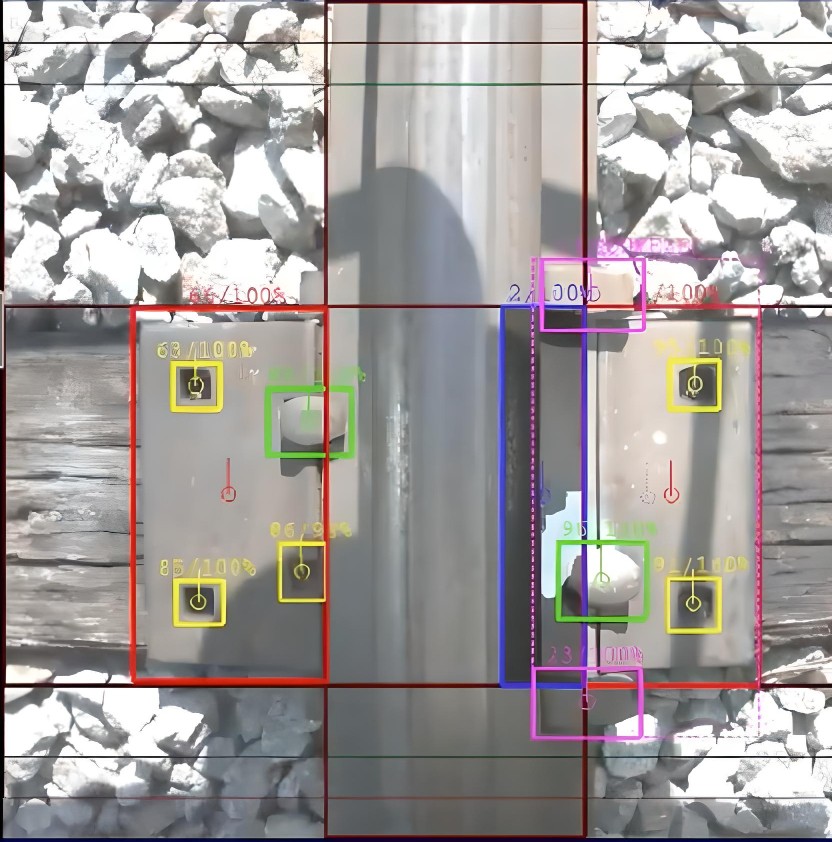

In keeping with Harsco Rail’s commitment to innovation, the TX16 leverages technology to further enhance both safety and performance. Each machine is equipped with Harsco Rail’s Jupiter II Control onboard diagnostics system, and the Callisto ProTamp, an inertial-based non-contact measurement system that records track geometry. Once the track is recorded, all the best fit and correction values are automatically generated and stored for long-term use.

Harsco Rail President, Jeswant Gill, said:The TX16 is the result of decades of accumulated experience, and our continued commitment to innovation that meets the needs of our customers. I am excited to introduce this game-changing equipment to Interchange attendees, and to our global customer base.

About Harsco Corporation

Harsco Corporation is a global market leader providing environmental solutions for industrial and specialty waste streams, and innovative technologies for the rail sector. Based in Camp Hill, PA, the 11,000-employee company operates in more than 30 countries. Harsco’s common stock is a component of the S&P SmallCap 600 Index and the Russell 2000 Index.

About Harsco Rail

Harsco Rail, a worldwide operating segment of Harsco Corporation, is a technological and innovative global supplier of railway track maintenance products and services. Harsco Rail provides expert engineering, vehicles and equipment, innovative technology, safety technology, dedicated parts and services, contracting services and quality maintenance from nine main locations in the United States, United Kingdom, Germany, India, Brazil, China and Australia.