Railway systems depend on various technologies to ensure smooth, safe and efficient rail operations, with axle counting and track circuit systems playing essential roles in this.

While both technologies serve the fundamental purpose of monitoring and detecting train movements, axle counters have emerged as the preferred choice for operators worldwide. This is largely thanks to a number of different features and benefits associated with this technology, such as high levels of reliability, availability and safety when compared to track circuit systems.

Track Circuits: a Conventional Method of Train Detection

Track circuit technology has formed the cornerstone of railway signalling systems for decades, thanks to its simple operating principle. This principle largely consists of using railway lines to complete an electric circuit. In a typical setup, a low-voltage electrical current is sent through one rail and received by the other, with an insulated joint or gap separating the individual track sections. These sections are connected to a power source at one end and a detection relay or receiver at the other. The power source continuously sends a low-voltage current through one rail, and the current flows back through the other rail to the receiver, thus completing the circuit.

When a train is absent from a track section, the current flows uninterrupted through the rails to the receiver, which in turn indicates that this particular section of track is clear. However, when a train enters the section, its axles which are made of conductive metal bridge the gap between the two rails, creating a short circuit, or a shunt. The short circuit subsequently diverts the current through the train’s axles, instead of the entire length of the rail back to the receiver. The fact that the current gets diverted causes the relay at the end of the circuit to de-energise, signalling that the track section is occupied.

Axle Counting Systems and Their Worldwide Adoption

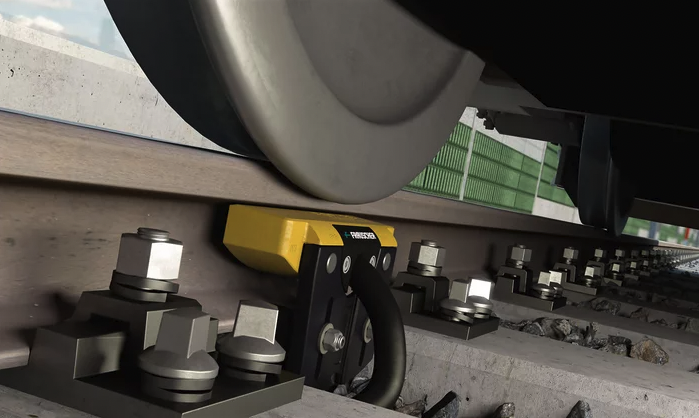

Axle counters are used for a variety of purposes in the field of railway signalling, especially in instances where highly reliable and available train detection systems are required. Due to their overall performance and high levels of availability and reliability, axle counting technology has emerged to be the cornerstone of modern railway signalling. Unlike track circuits, axle counting technology depends on the use of inductive sensors which detect train wheels that pass a designated point on the track. Each time that a train wheel traverses the sensor, a signal is generated which is then sent to the evaluation unit for further processing.

As the name suggests, axle counting consists of counting the axles of a railway vehicle entering a track section – if an axle of a rail vehicle traverses the detection point, the axle counting system increases the counter reading of the respective track section by one axle. If an axle of a rail vehicle traverses the detection point out of a track section, the system decreases the counter reading of the respective track section by one axle – this procedure works in both directions. If the number of axles counted in equals the number counted out, the track section is clear. However, if the number of counted in axles exceeds the counted out axles, the track section is marked as occupied. If a negative axle count or an error occurs, a fault condition is triggered – in such cases, the system defaults to a safe state by marking the track section as occupied until the error is resolved.

One major advantage of axle counters over track circuits is their ability to provide the operator with advanced functionalities and options which far exceed the standard data for train detection. This data includes information such as direction of travel, number of axles, speed as well as diagnostic data. Due to their overall performance and advanced functionalities, modern axle counting solutions form a crucial part of signalling systems and railway infrastructure worldwide.

The Frauscher Advanced Counter FAdC® as a Cutting-Edge Axle Counting System

Applications and Interfaces of the FAdC®

The Frauscher Advanced Counter FAdC® is a widely renowned axle counting system manufactured by Frauscher Sensor Technology. Since its inception, the FAdC® has been utilised in numerous projects globally, thanks to the extensive benefits it provides to operators. The FAdC® offers the ideal base for responding to customer and market specific requirements, in line with the most stringent safety standards, as stipulated by Safety Integrity Level 4. This in turn makes the system an ideal choice for vital applications such as level crossing protection and track vacancy detection, among many others. Furthermore, the fact that no electronics are required in the track connection box, means that no electronic components are exposed to direct environmental influences, reducing maintenance requirements and system complexity, while saving costs.

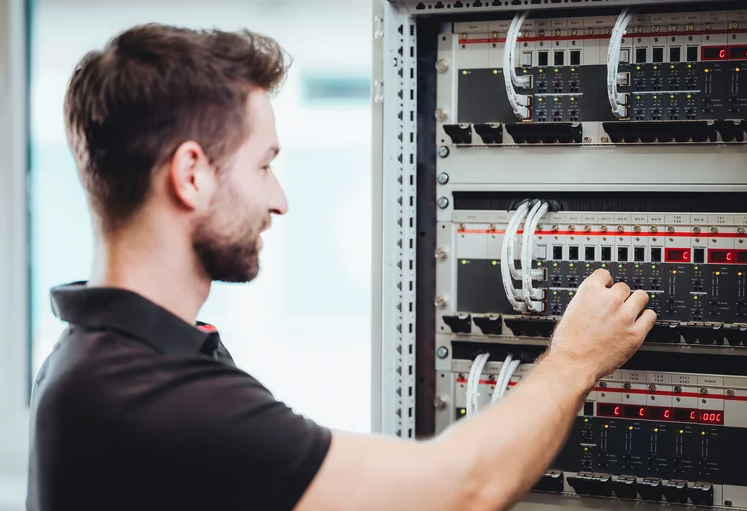

When it comes to integration with higher ranking systems, the FAdC® offers flexible architecture thanks to a wide range of interface options which guarantees a seamless incorporation into existing systems. With regards to interfaces, the FAdC® offers three distinct possibilities: relay interface, optocoupler interface and an Ethernet interface. The FAdC® offers a relay interface with the IO-EXB board, thanks to which two track section information can safely be output per IO-EXB and interfaced to a higher-ranking system like a relay based interlocking system. More importantly, thanks to its communication board, the FAdC® also offers a state-of-the-art Ethernet interface which supports many fail-safe protocols such as Frauscher Safe Ethernet, customer-specific protocols as well as EULYNX. With the implementation of EULYNX, the FAdC® delivers a seamless, standardised interface for signalling systems.

Wide Range of Configuration Options

Moreover, the flexibility and scalability of the FAdC® allows the system to be tailored in accordance with specific project requirements to ensure the most efficient and economic project realisation – this also includes the possibility to establish a fully decentralised architecture. The scaleability of the FAdC® is one of the most noteworthy advantages of this system, involving an array of technical and economic benefits in terms of lower system complexity and low maintenance and set up costs.

Decentralised architecture in railways significantly enhances the system’s robustness and scalability. Unlike centralised systems, where a single point of failure can lead to widespread disruptions, decentralised architecture ensures the spread of signalling functions across multiple interconnected nodes. This set up allows the railway network to maintain operations even if one part of the system encounters issues which increases the overall reliability and reduces downtime. In every location where the FAdC® is present, as many detection points as required can be added. The decentralised FAdC® locations can be subsequently connected together via a telecommunication network, such as fibre optics – likewise, the decentralised locations can also connect to a centralised location. This arrangement often presents a considerable benefit for the operator in terms of a simplified network architecture, reduced amount of cabling and lower project costs.

Intelligent Functions

Despite the fact that the FAdC® delivers unparalleled reliability and availability, several innovative functions have nonetheless been incorporated into the system to ensure best performance.

One of such innovative functions consists of Counting Head Control CHC which is highly configurable to suit the requirements of any project. The main function of CHC is to avoid counting errors and fault messages from being generated due to interference from external factors. These, among others include road traffic, metal objects or debris on track surfaces, all of which can produce a false count.

Thanks to CHC, counting heads can be switched to a stand-by mode in cases where adjacent track sections are clear to avoid disturbances which can generate errors. Furthermore, the number of supressed disturbances or false detections within the system can be freely configured, meaning the track section only turns to occupied once the set threshold for disturbances is reached. Once an approaching vehicle enters either of the adjacent track sections, the suppression is immediately deactivated, resulting in normal fail-safe train detection in line with SIL 4 requirements.

Similar to CHC, the Supervisor Track Section function, abbreviated to STS is a special feature included in the FAdC® which is designed to increase availability of railway operations. The STS is an automated fault correction process which ensures that if an error on track occurs, the system is able to automatically reset itself, without requiring time-consuming manual intervention.

The working principle of the STS consists of overlaying individual track sections with a supervisor section. If there is an error on a track section but the corresponding supervisor section is clear, the system will automatically preform a reset. Similarly, a faulty supervisor section is reset if the corresponding track sections which are covered by this STS are clear.

The arrangement in which counting heads on track sections are overlayed with supervisor sections is highly configurable and contingent upon the specific project needs and requirements. STS is fully compliant with SIL 4 operation and can be used in a multitude of applications such as track vacancy detection. In this sense, the STS provides additional availability while upholding the highest level of safety.

These two features represent just a glimpse of a series of innovative and powerful features that grant integrators and operators possibilities to simplify their systems and operating procedures. Since the FAdC® forms the backbone of Frauscher’s axle counting systems, customers benefit from continuous improvements and new developments, with a short innovation cycle.

This article was originally published by Frauscher Sensor Technology.