Apart from producing high-quality gearboxes, IGW also strives to be a dependable full-service provider within the rail market. That means we are capable of taking on overhaul projects both for rail gearboxes made by us or by other manufacturers. In that vein, our colleagues in the Czech Republic are currently using their new wheel press for a first big project for NordWestBahn in Germany as well as handling a big overhaul project for a Lithuanian customer.

Breaking in the New Wheel Press

While we are widely known for making top-quality gears and gearboxes, we are also setting great steps towards becoming a full service provider to our customers. In a new project for NordWestBahn, a private transit authority in Germany, we will be using our wheel press for its first major project. This will see us replace wheels as well as overhaul journal bearings. We were able to secure this project thanks to our eye for detail and customer-oriented approach.

This project is an exciting opportunity for us to grow and demonstrate our expertise. After all, this being the first major project involving our wheel press, we get the chance to show that we are capable of handling wheelsets too. And judging by the first results, we are doing very well, which, in turn, means that we are making great strides in becoming an even better service provider.

Another Important Project with Its Own Challenges

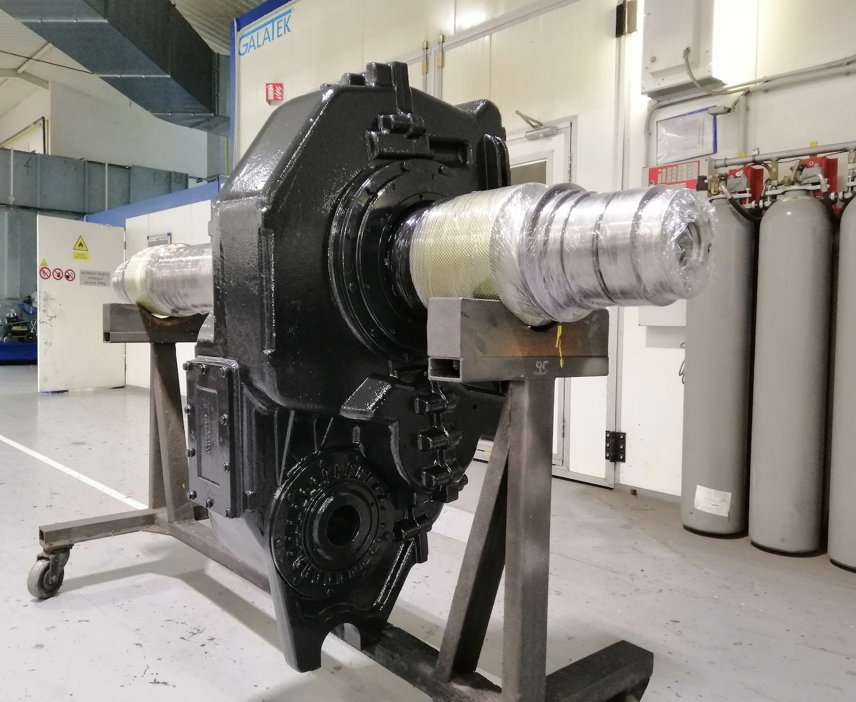

Aside from getting to grips with our wheel press, we are also overhauling gearboxes and maintaining wheel axles for a Lithuanian customer. Maintaining the axles means in this case removing the molybdenum layer and replacing with a new one. We were chosen for this particular project because of our ability to handle all of the customer’s demands in a short period of time.

As it stands, we are 1/3 along the way in the process and running right on schedule despite the coronavirus outbreak. Nevertheless, time remains the biggest challenge. Aside from urging ourselves to stick to the deadlines, we are also dependent from suppliers and partners. In the end, though, the entire project is scheduled to finish on time by September 2021. Reaching al the deadlines has not been easy, especially in times of a pandemic, but it makes us all the more proud of the hard work of everyone involved.

Just like the project for NordWestBahn, this project provides us with a great insight in our own work. Indeed, we get to see and inspect the condition of our gearboxes after a certain mileage. This gives us a lot of valuable information for future overhauls.

Learning and Developing

As we take on projects like these ones, we get the opportunity to show that our current approach is working. After all, by offering a full range of services, we eliminate our customers’ need to look for several partners. Instead, they will find that we provide the answer to all their aftermarket needs. In the end, we are very much looking forward to offering these services to more clients.