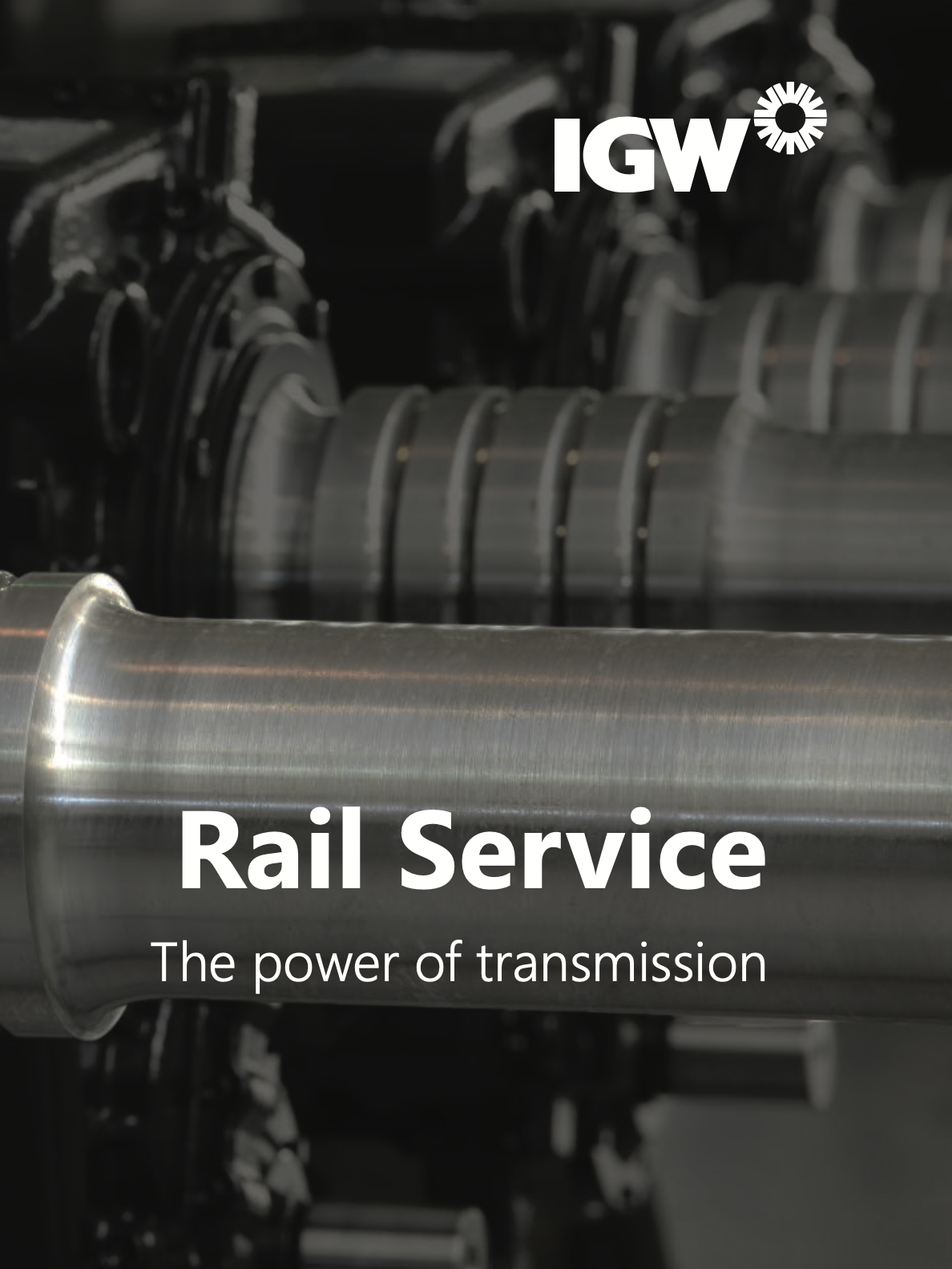

Railway Drive Systems

The rail industry requires a highly specialized approach. Millions of people and companies depend on trains, trams and metros every single day. Reliability is crucial. IGW has provided customized, robust and efficient drive systems for this unique market since 1993. We have delivered so far over 100,000 gearboxes and gear couplings for the most prestigious rail projects all over the world.

Our commitment to operational excellence makes the difference, enabling us to combine the best value on the market with a tailor-made approach. The unrivalled efficiency, reliability and long service life of our solutions all contribute to the lowest total life cycle cost for the customer.

With plants in Belgium, the Czech Republic, Romania, India, China and the USA, IGW is close to customers all over the globe.

IGW is part of BMT drive solutions, a division of the BMT Group. The drive solutions division serves customers in three business lines: automotive, industrial and rail. Our shared know-how, commitment to innovation and global presence makes us a formidable force in the gear system market.

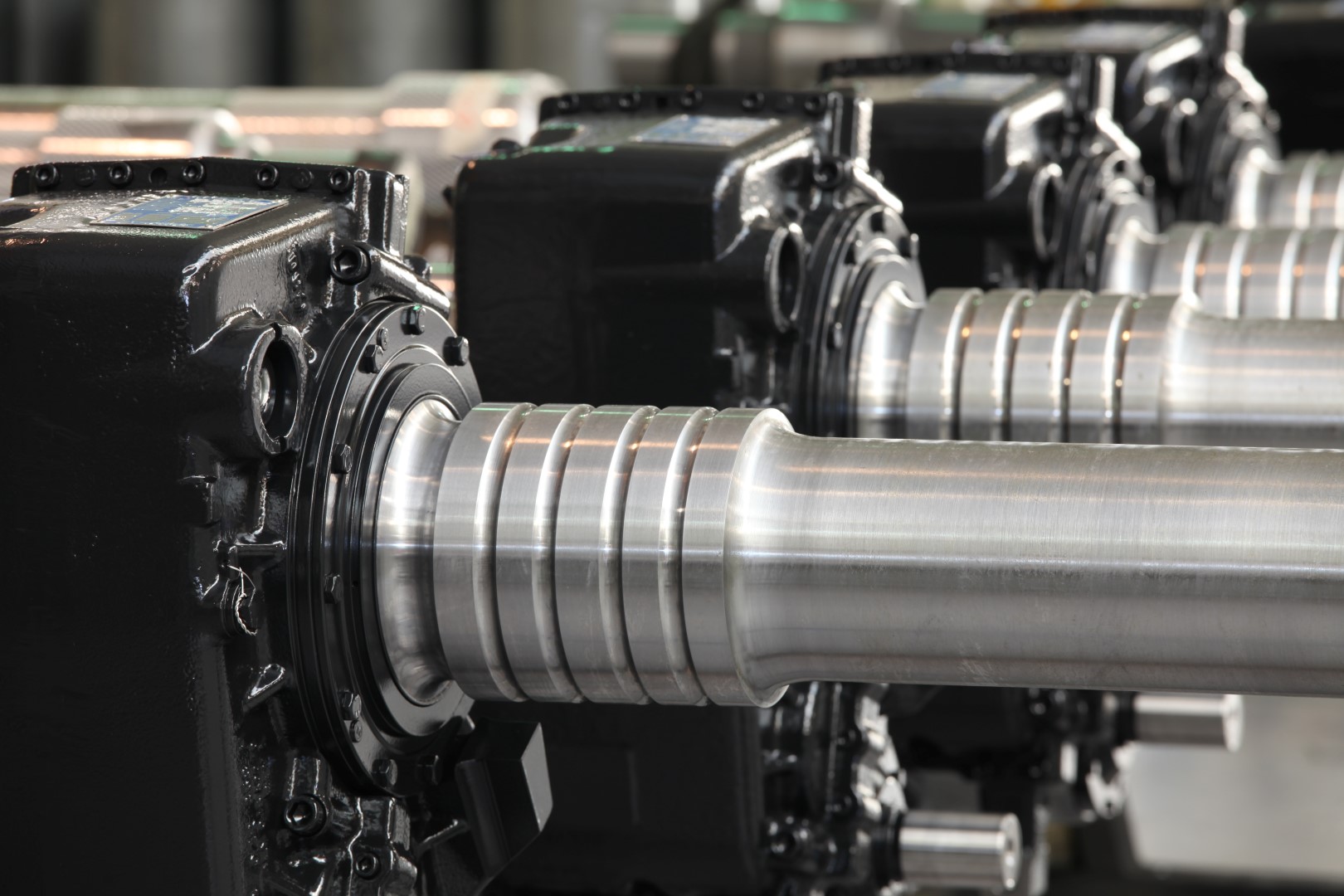

Gearboxes for Railway Applications

Your equipment needs to perform well under all conditions; hot or cold temperatures, mountains or countryside environments… Therefore, we make sure all the products we provide to you are tested in the right circumstances. From heavy duty locomotives to light rail applications, from low speed city metros to very high speed trains, IGW is your engineering partner for any drive solution. We offer a complete service, from an extensive requirement analysis to premium production and future overhaul services.

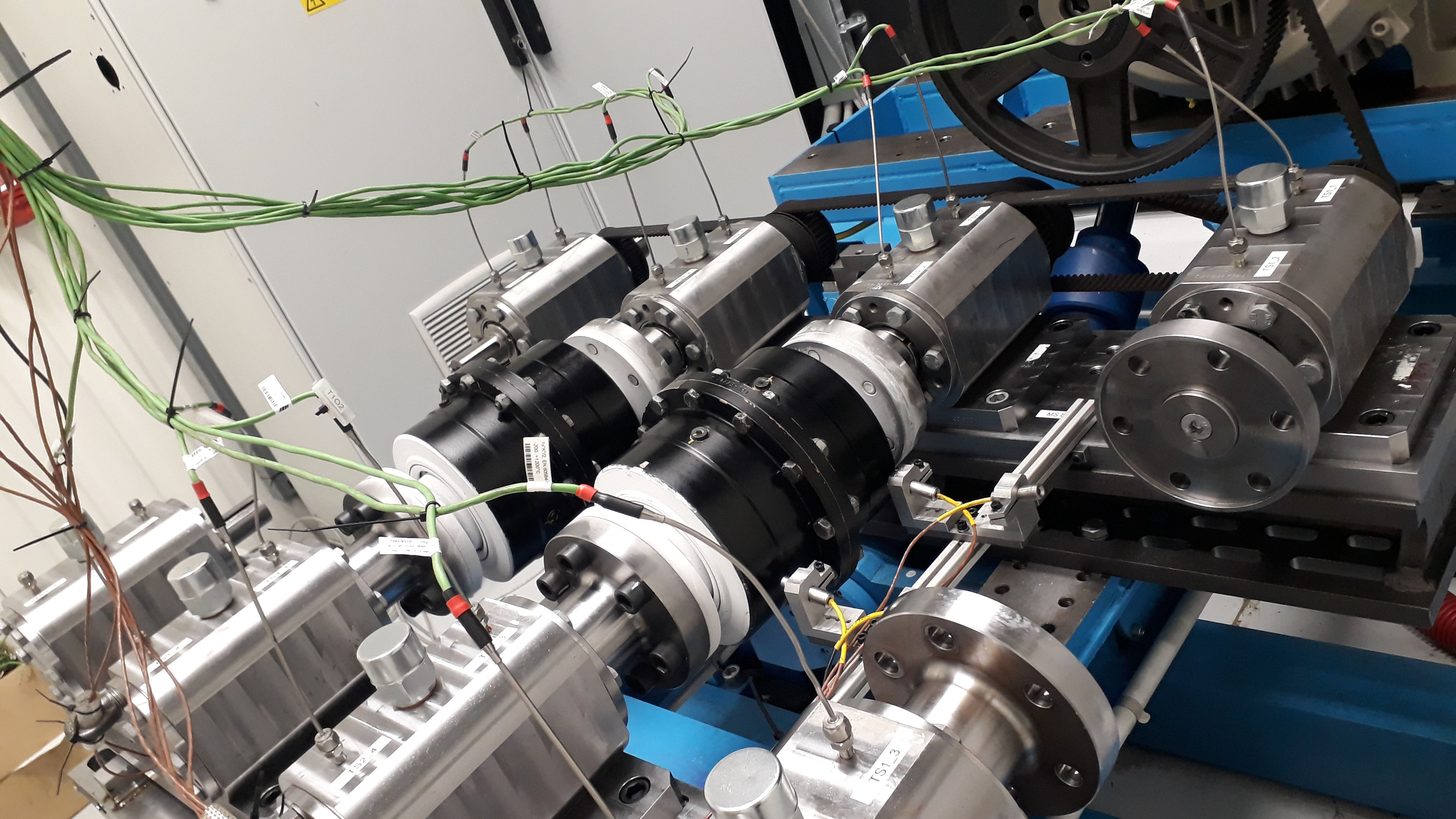

Couplings for Railway Applications

Many years of field experience have given us the insight to focus on design features with a proven reliability, and to avoid those that have caused problems in the field. Using the latest engineering software and simulation tools, we ensure lifetime performance and minimal life cycle cost are built in from the design phase. All IGW couplings are subjected to rigorous prototype testing, using our gearbox testing equipment and experience to their full advantage.

Global Support Services

As an OEM or railway operator you are looking for perfect service partners who can offer a comprehensive service. A good service is customized, complete and above all, trustworthy. Therefore, rely on IGW, a global leader in railway drive systems since 1993 and an ideal partner who offers you a range of services for railway drive systems, couplings and complete wheelsets.