Virtek’s Iris 3D Software Supports Welded Assembly Operations with Enhancements that Address Quality, Productivity and Skilled Labor Shortage

Virtek Vision announces several enhancements to its preeminent Iris 3D laser projection system enabling job shops and original equipment manufacturers (OEMs) to accelerate the manufacture of and improve the quality of welded assemblies and components. It also addresses the manufacturing sector’s ever-increasing talent shortage* because the system requires no prior training or experience to operate.

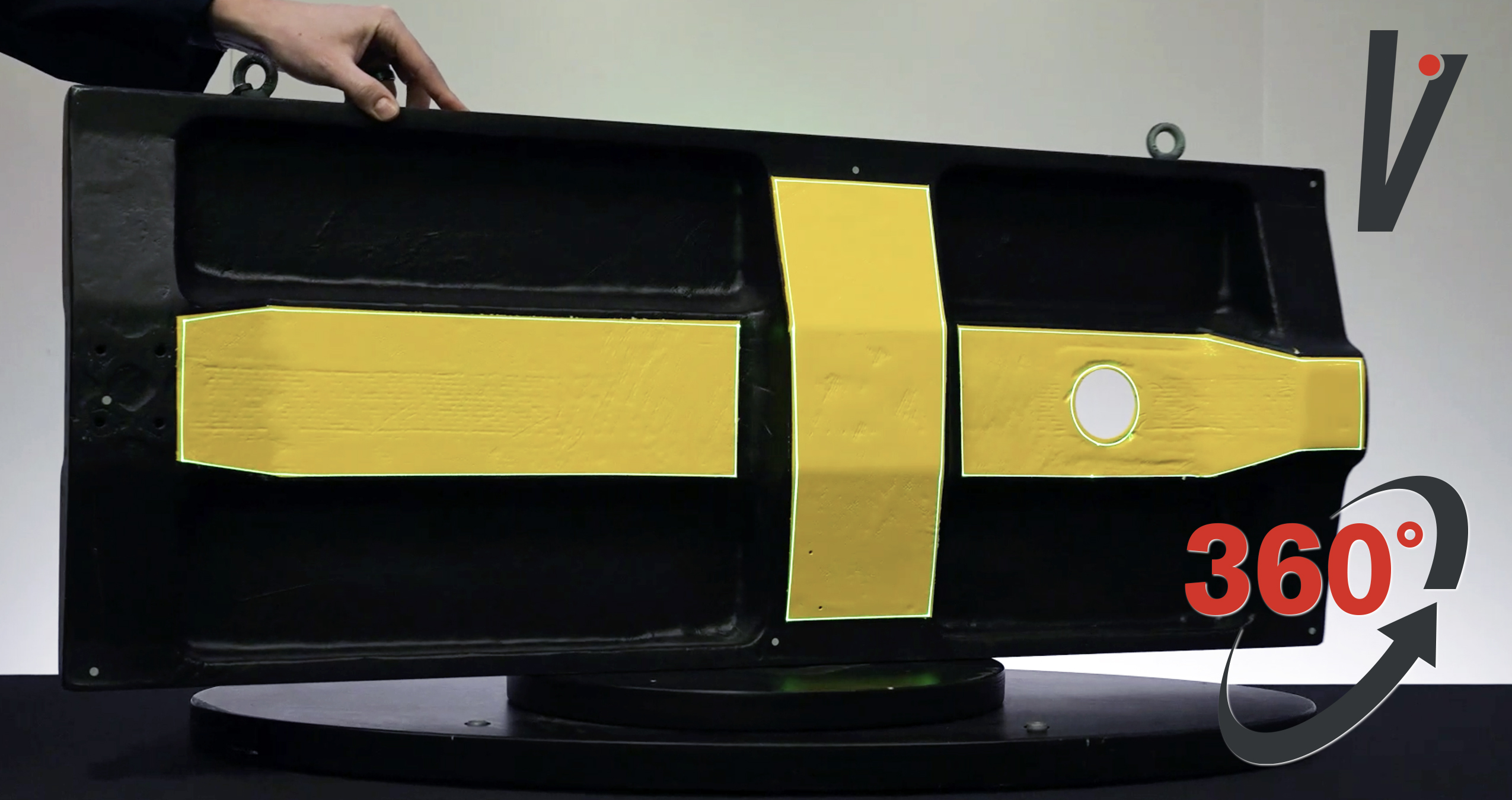

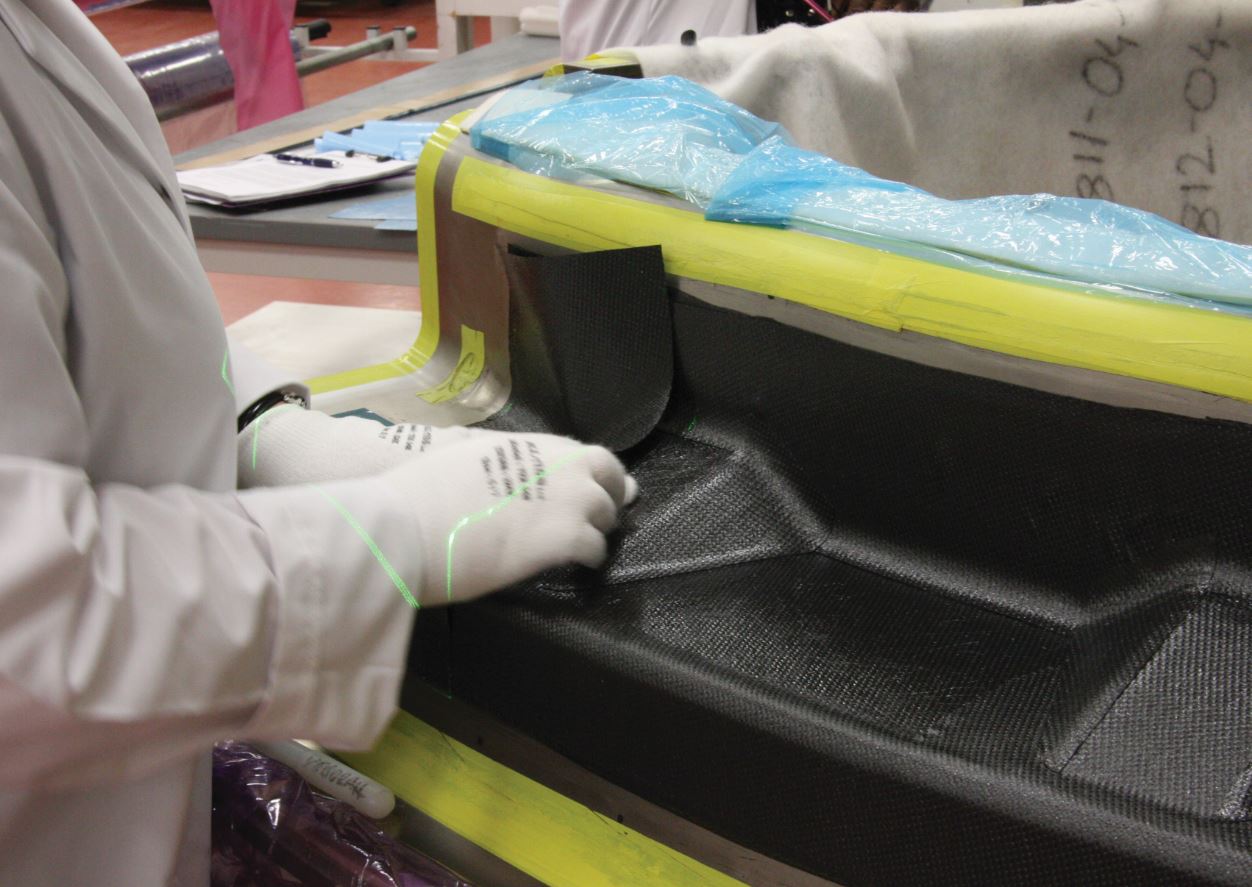

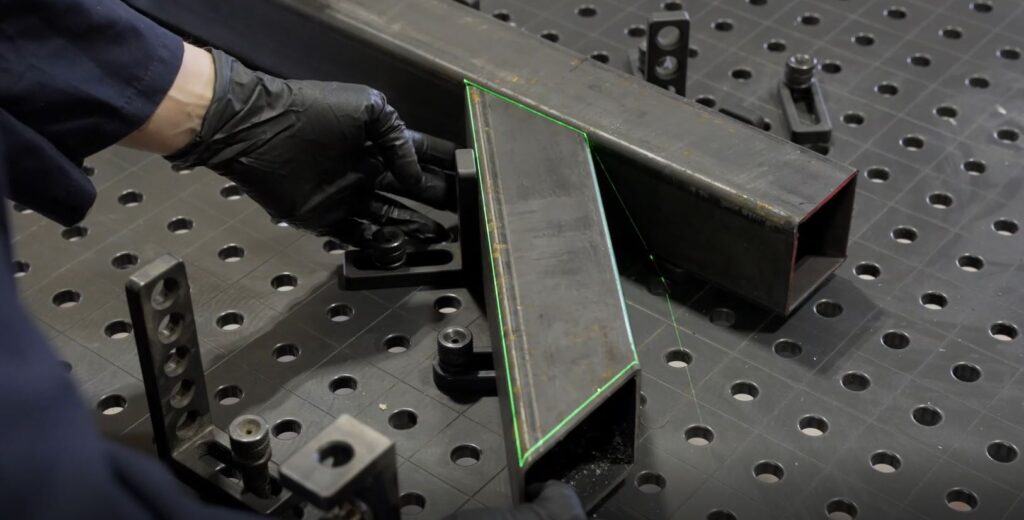

Using a standard CAD file (no projection files required), Iris 3D identifies the part geometry (mounting brackets, studs, bushings, etc.), determines each part’s exact position in 3D space and projects high-visibility laser lines to direct workers in the placement of each part on the assembly, including drill locations, punch locations, fixture placement and precise assembly positions. Iris 3D software achieves accuracy of +/- 0.015 inches or +/- 0.38mm for most applications, making measurement errors and rework a thing of the past.

The Iris 3D software interface is simple and intuitive so employees with little to no training can quickly become productive. It gives manufacturers the power to visualize the finished assembly or weldment before work begins. The software also eliminates time spent on interpreting drawings, fixturing, layout, marking and component positioning because it performs alignment automatically, with no operator intervention required, enabling employees to begin work immediately after file selection.

Organizations can integrate multiple projectors for very large work areas by fix mounting units over a work cell or assembled on a Virtek mobile stand to facilitate flexible work configurations. Projected laser lines are safely and clearly visible with the human eye, so protective eyewear and safety training are unnecessary.

Dietmar Wennemer, president and CEO of Virtek, said:For nearly four decades, Virtek’s engineering and product management teams have worked with customers and partners to drive product innovation and continuous product enhancements. This is yet another example of delivering what our customers need to improve their quality, increase efficiency and profitability.

Iris 3D offers easy “Pick-and-Project” (PnP) functionality of specific components in the CAD data for simpler assemblies and one-off projects. It also supports extensive pre-designed workflows for complex or repetitive projects to visualize the end product, easy setup of fixtures before you begin your weldment.

Sean Francoz, Virtek’s director of Product Management, said:Our Iris 3D technology has proven to be a game changer for job shops and OEMs, enabling them to increase productivity by two or three-fold and delivering a return on their investment in less than a year. When you factor in how it also helps address the skilled labor shortage and prevents costly rework and wasted material caused by setup or measurement errors, business owners often find the purchasing decision to be very straightforward.

The latest Iris 3D system was unveiled at the International Manufacturing Technology Show (IMTS), North America’s largest manufacturing trade show in September this year, and will be demonstrated next week, Nov. 8-10 at Fabtech in Atlanta, GA (Hall B, booth #B7851).

For more details, and to discuss your organization’s unique challenges, contact your local Virtek sales representative.

*In a 2018 study, Deloitte Manufacturing Institute estimated that more than 50 percent of open positions in the U.S. manufacturing industry will remain unfilled due to a skills shortage.

This article was originally published by Virtek Vision.