Open House to the Future – ROBEL In-House Exhibition 2019.

For four days, more than 500 rail infrastructure experts have used the in-house exhibition at the ROBEL premises to engage in the current topics of track maintenance.

As a consequence, the conversations at product demonstrations, presentations and workshops have been all about more safety, process velocity and environmental protection in rail construction.

For ROBEL, the solution lies in the application of new technologies on the one hand and in the modernisation and extension of the machine life cycle on the other. How far these solutions have already matured, the three business units demonstrated within their own facilities on site and live at the factory tracks:

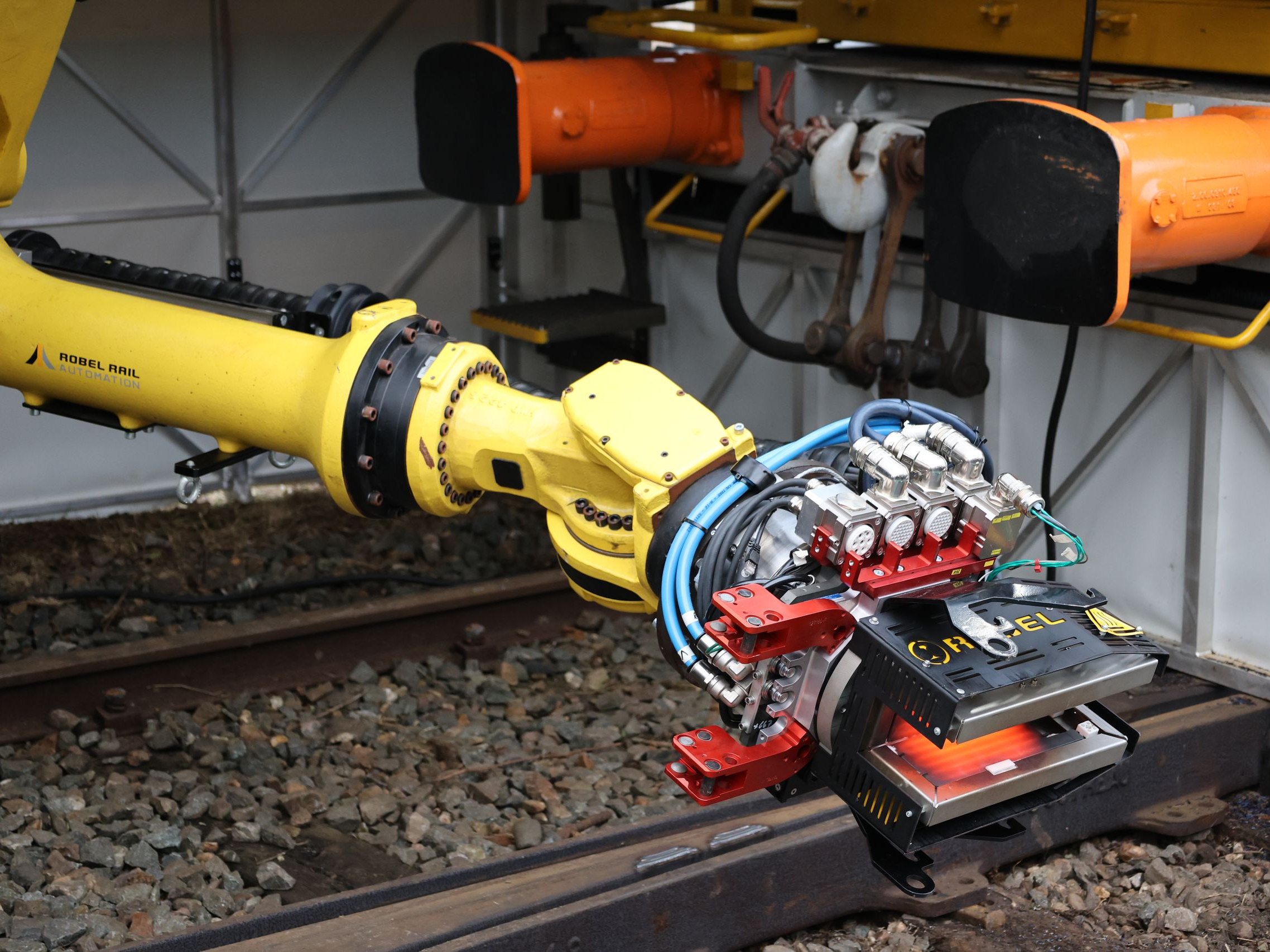

- Robot controlled cleaning of rails and other surfaces with dry ice

- A complete spot repair realised by using battery powered machines only

- Remote maintenance and service via data glasses and online parts catalogue

- Retrofit – the total overhaul of track vehicles in the massively extended and Europe-wide certified service center

ROBEL CEO Wolfgang R. Fally appreciates the trade dialogue on home soil:It is a pleasure and enrichment for the whole ROBEL team to talk with customers and partners from all over the world about the future of track maintenance – you positively feel the collective enthusiasm for the rail.