NEXTSENSE GmbH

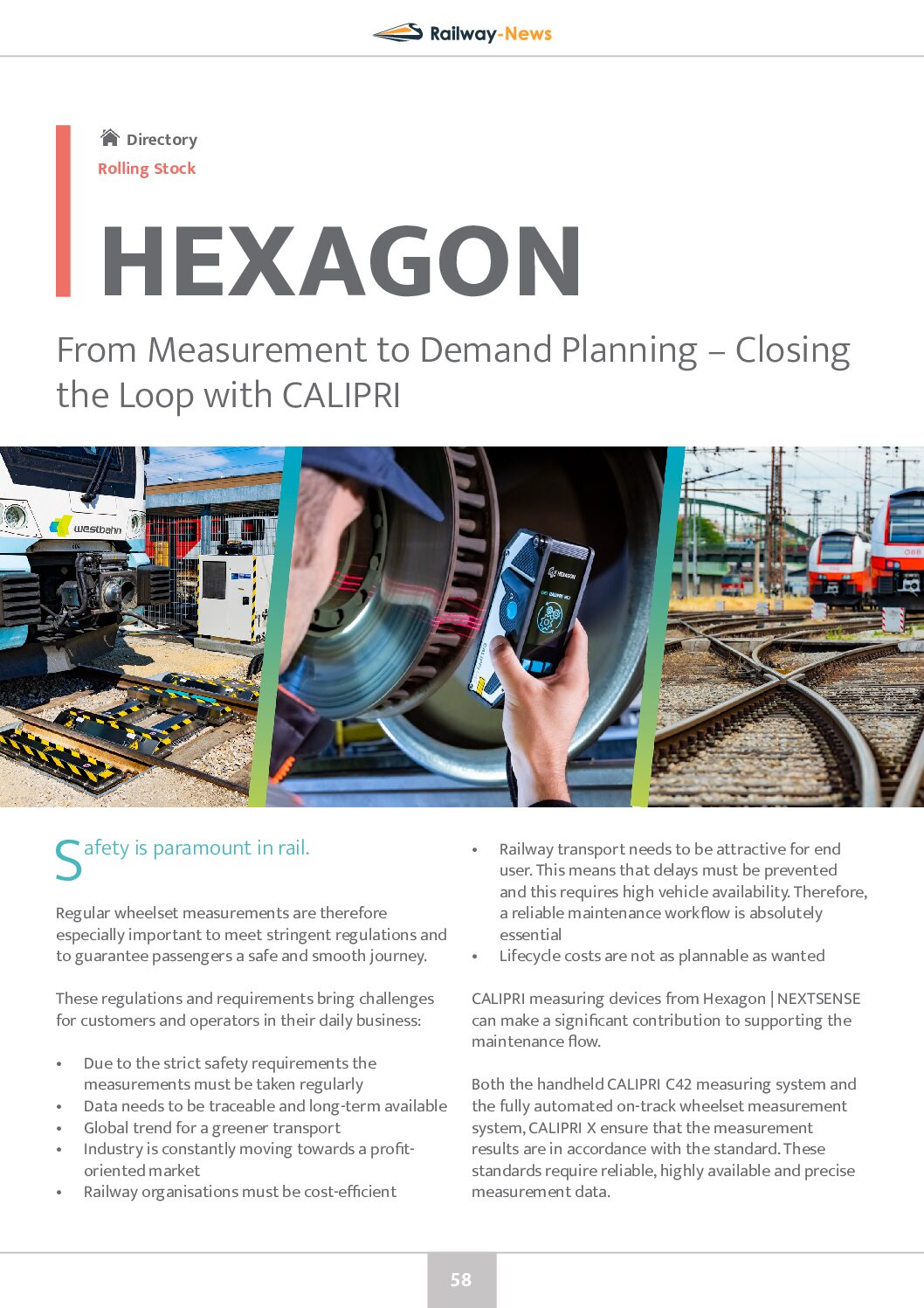

From Measurement to Demand Planning – Closing the Loop with CALIPRI

This article first appeared in the Railway-News Magazine Issue 4 2023.

Safety is paramount in rail.

Regular wheelset measurements are therefore especially important to meet stringent regulations and to guarantee passengers a safe and smooth journey. These regulations and requirements bring challenges for customers and operators in their daily business:

- Due to the strict safety requirements the measurements must be taken regularly

- Data needs to be traceable and long-term available

- Global trend for a greener transport

- Industry is constantly moving towards a profitoriented market

- Railway organisations must be cost-efficient

- Railway transport needs to be attractive for end user. This means that delays must be prevented and this requires high vehicle availability. Therefore, a reliable maintenance workflow is absolutely essential

- Lifecycle costs are not as plannable as wanted

CALIPRI measuring devices from Hexagon | NEXTSENSE can make a significant contribution to supporting the maintenance flow. Both the handheld CALIPRI C42 measuring system and the fully automated on-track wheelset measurement system, CALIPRI X ensure that the measurement results are in accordance with the standard. These standards require reliable, highly available and precise measurement data.

CALIPRI C42

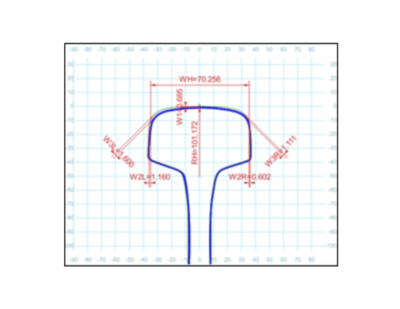

The multifunctional CALIPRI C4x series enables the combination of several measurement modules in one measurement device. If, for example, the modules for wheel profile, brake disc, wheel diameter and back-toback are combined, the result is a measuring device for evaluating a complete wheelset. CALIPRI Prime, on the other hand, focuses on wheel profile measurement and thus replaces conventional mechanical gauges.

The measurement process is based on laser light section technology. The user guides the sensor over the measurement object by hand. It is not necessary to precisely maintain the distance and angle of the sensor. This is achieved by using the patented CALIPRI principle and its unique tilt correction. During the process, the profile is captured and evaluated from different perspectives. Once measured, the data is immediately ready for analysis and transfer.