Vibrations and the impact of high-speed trains are affecting track geometry to a huge scale. Besides heavy wear and tear of the track, the track gage, crosslevel and alignment are getting affected. Thus, the pressure on predictive track maintenance is rising. Checks need to be done at a higher frequency, with faster measurements and more precise than ever. Nextsense, measurement expert for the railway industry, developed the CALIPRI Track Geometry Gauge – an add-on to their well-known portable measurement system.

A race has started among manufacturers of railway vehicles to build the fastest train in the world. Trains speeding at 300 km/h along tracks is quite common nowadays. The fast speed tests the material of tracks and trains to their limits. But speed is not the only threat in railway infrastructure. Climatic conditions and natural disasters can do major harm to track geometry as well. Constant checks of wear and tear become as crucial as inspections of track geometry in general. After all, safety can only be ensured if critical parameters are kept in place. With the CALIPRI Track Geometry Gauge track maintenance operators have a handy and easy-to-use measurement device at their hands which gathers all important parameters for track maintenance – including track gage, cross level, rail cant and twist.

Handy and Hand-Held

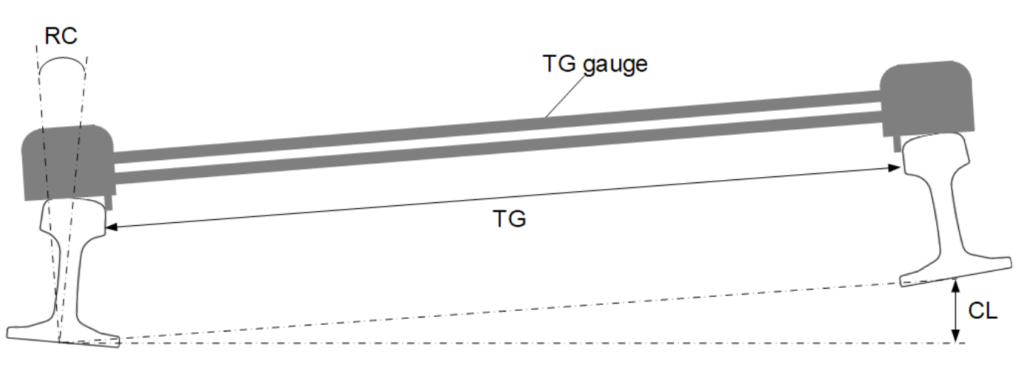

The measurement system equips operators with a handheld sensor, a measurement gauge and a tablet PC for displaying the results. The CALIPRI sensor measures the complete profile of the rail. The gauge is needed in order to get additional information like track gage, cross level, rail cant and twist. For use, simply put the gauge in a 90-degree angle on the tracks. The placement is easy and fast due to two stop bolts on the left side, helping the operator to position the gauge. A tensioning mechanism helps to fix and keep the gauge in place.

Contactless and User-Independent

The contactless measurement starts by swiveling the sensor around the rail once. Soft vibrations indicate that the measurement data were gathered and the measured profile will start to appear on the tablet PC. The measurement itself only takes a few seconds and is done by one laser but three laser lines – the one in the center performing the actual measurements and the surrounding ones eliminating rolling and tilting errors. Therefore, user-independent and highly precise results are always ensured. The CALIPRI technology integrated in the device is patented and a development of the laser light section technology.

The Gauge Parameters

Measuring the profile of the rail will give important indications about the wear and tear of the track. Additionally – with the gauge in place – other important parameters will be delivered. Like for example the track gage. Due to aging and different conditions of the sleepers the gauge distance usually is not uniform along the whole track. Still, the parameter needs to stay within a specific range otherwise trains wouldn’t be able to operate safely anymore.

When a train takes a curve, centrifugal forces come into play. In order for the train not to derail in a curved track, a positive level difference between the outer and inner rails needs to be in place. The level difference between the rail heads – also called crosslevel or superelevation – is one key parameter to calculate at which speed a train can travel through a curve. The CALIPRI Track Geometry Gauge measures the crosslevel in curved tracks and therefore can help to support the overall safety of train rides.

Besides track gage and crosslevel, the CALIPRI Track Geometry Gauge measures the rail cant which directly influences the dynamic interaction of the track and the vehicle. Furthermore, the software calculates the twist of the track in order to detect irregularities. The calculation determines the difference between two elevation values at a defined distance along the track.

Higher Safety Meets Decreasing Costs

The advantages of higher track maintenance are quite apparent. First and foremost, it is about safety. But also the longer life time of the tracks, the reduction of operational costs and of fuel expenses are on top of the list. With the CALIPRI Track Geometry Gauge, Nextsense created a portable system that will contribute significantly to making measurements in track maintenance easier and more precise. Thus, contributing to safer travelling on rails.