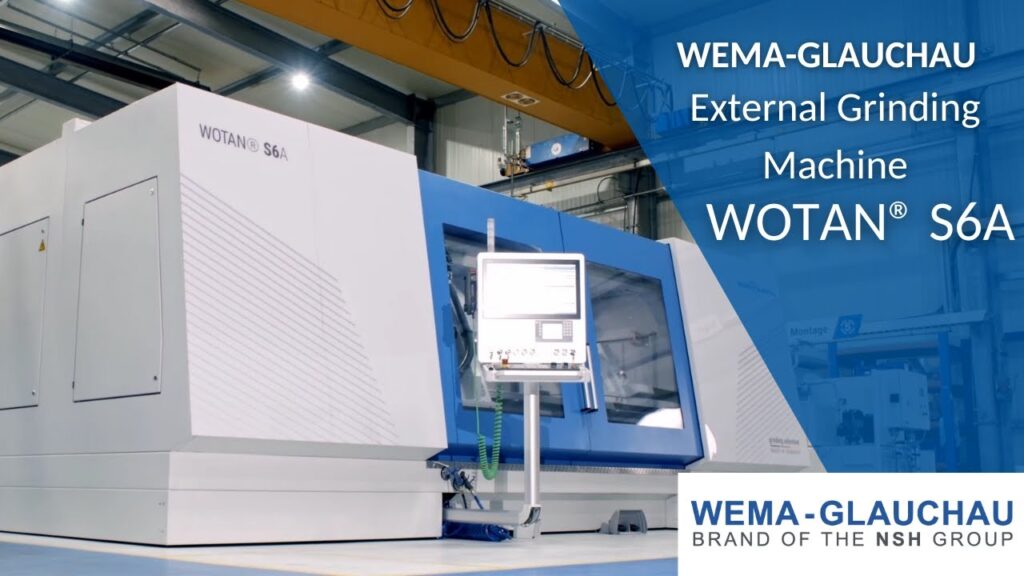

Today we present together with the film team of our video partner Video Vision the new WOTAN S6A external grinding machine of our brand WEMA-GLAUCHAU.

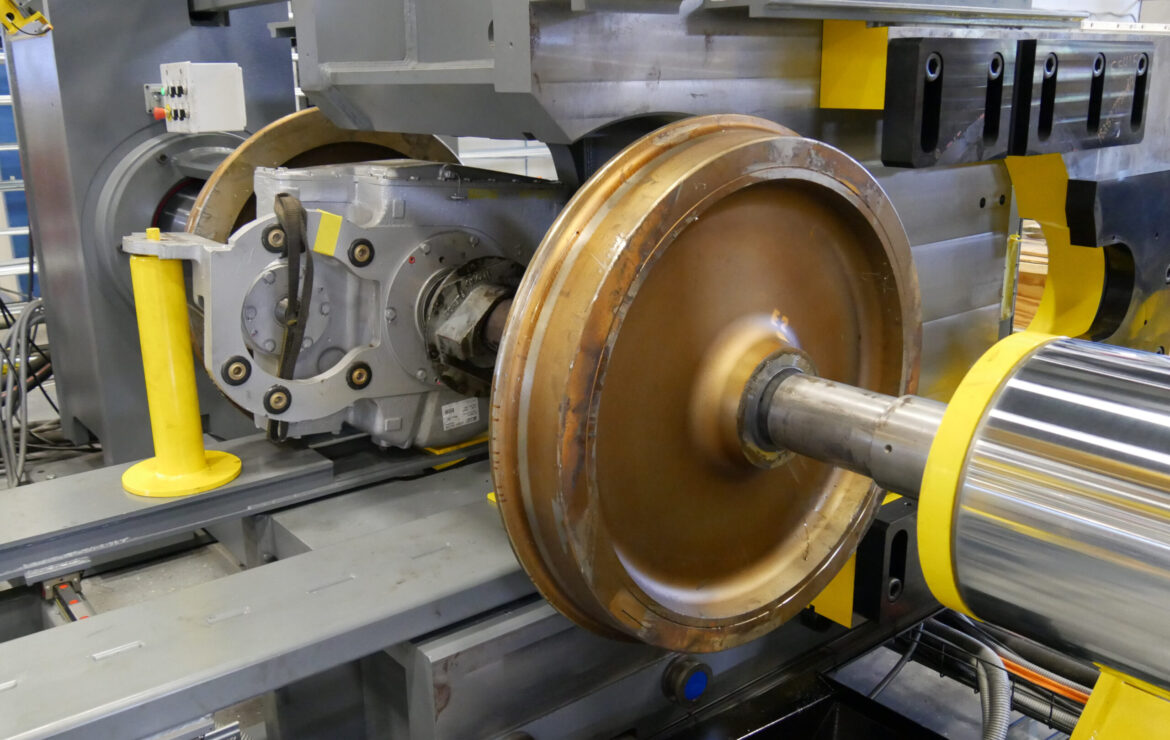

The WOTAN S6A 3000 was newly developed in Glauchau and is suitable for external and internal cylindrical grinding of heavy and long components. The machine is used in the following areas: railway, aerospace, general mechanical engineering and automotive.

The cross-slide configuration allows safe machining of components with a length of up to 3000mm and a weight of up to 1.5 tons with minimum space requirements due to the very rigid machine design, highest precision can be achieved even with high dynamics and in harsh environments. The S6A is equipped with a direct-drive workpiece spindle with a maximum speed of 300 revolutions per minute, with a run-out accuracy of up to 0.5 µ and with a maximum torque of 840Nm. It also features a hydraulically clamping tailstock with a stroke of 150mm and an infinitely adjustable rotary table, which allows angular adjustment of up to 270 degrees, depending on the equipment. The workpiece spindle as well as the reistock can be individually positioned on the machine table.

Further equipment features are:

- grinding unit that drives a grinding wheel with a diameter of 760mm and a width of 200mm

- swiveling measuring probe for automatic detection of the zero point

- dressing spindle with an NC dressing roll for long tool life and accurate dressing results

- an in-process measuring device which can reach and measure any position on the component due to its separate axis

Furthermore, the machine is equipped with the latest generation of Siemens control and is programmed via the in-house factory-satt oriented user interface. A wide variety of technologies can be implemented with this grinding machine.

For example:

- the pure external cylindrical grinding in plunge-cut process up to diameters of 700mm

- external cylindrical grinding up to a length of 3000mm

- surface grinding

- as well as internal grinding

The maximum travels of the axes are 4000mm in Z and 600mm in X. The equipment can be adapted according to customer requirements, for example with two grinding supports, which makes it possible to optimize the production output by simultaneous machining on one workpiece. Furthermore, the spindle turret can be equipped with up to two external grinding spindles and one internal grinding spindle. This also enables the machining of very extensive and compact components in one clamping. With the WOTAN S6A, we have succeeded in developing a machine that combines the highest precision and flexibility in the machining of the largest components.

See the WOTAN® S6A in action here.

This article was originally published by NSH Group & NSH USA.