Tunnel Construction Monitoring for the U5 Metro Line Extension in Germany

Challenge

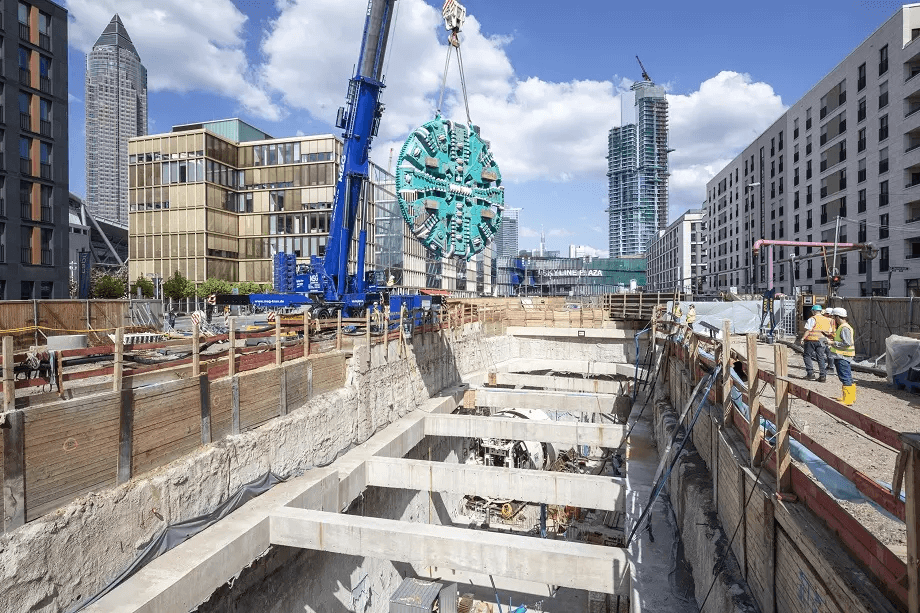

The U5 Stadtbahn Europaviertel is a metro line extension project that aims to provide public transport for a new city district with commercial areas, a park, 3,800 households and 30,000 people in Frankfurt. The underground section of the U5 metro line involves two tunnels with a total length of 1,720 m (860 m for each tunnel). Because of fragile infrastructure surrounding the site, and the general risks of tunnel excavation, PORR Group, the building contractor selected by project owner SBEV, needed to install monitoring equipment without impacting the construction work or disrupting city traffic.

Solution

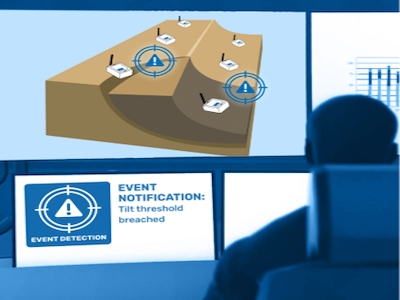

Project partner Angermeier Ingenieure installed around 100 geotechnical sensors and 400 geodetic monitoring points to carry out precise monitoring across the tunnel project. Multi-point extensometers were located at several points along the tunnel under public areas and roadways. And to automate data acquisition without installing long and expensive cables, the extensometers were connected to Loadsensing vibrating wire 5-channel data loggers. A wireless biaxial tiltmeter, which serves as a sensor and node in one, was installed to monitor the tilt of surrounding structures.

The battery-powered data loggers, installed in a covered manhole to prevent vandalism, send data wirelessly to a gateway installed on a temporary office on site. From there, the network transmits the data to an evaluation and visualisation system.

For connectivity, Loadsensing uses LoRa, a long-range, low-power wireless technology used by IoT networks worldwide. Features of the system include:

- Radio signals up to 32 times stronger than those of other wireless monitoring systems–strong enough to penetrate through metallic manholes.

- A star network topology that can cover a range of up to 2.5 miles/4 kilometres in a tunnel without any repeaters.

- Low-power edge devices that can last for up 10 years or until project completion, around 2025.

“The Loadsensing set-up and installation was extremely simple. The data could be immediately transferred to the evaluation and visualisation system. Its main advantage is its ability to send radio signals from under manholes and over a long distance.”

Benefits

Loadsensing eliminates the need for expensive cabling that could disrupt traffic and construction work. Setting up the system is simple and data can be acquired even from sensors inside manholes.

Ultimately, the monitoring system helps to ensure that the environment is safe not only for workers but also for people who live and work in the city centre.

Advantages

- Unintrusive and vandalism-proof monitoring equipment and power supplies in public areas

- Radio signals that can pass through manholes and span long distances

- Simple and effective installation, without the need for cables

Download the Success Story here.

This article was originally published by Worldsensing.