TDK Releases Tronics Axo®315 – High Performance, Force-Rebalance SMD MEMS Accelerometer with Digital Interface

TDK Corporation (TSE: 6762) announces the release of Tronics new AXO315 Accelerometer, a miniature high performance 1-axis closed-loop MEMS accelerometer with a 24-bit digital SPI interface and SMD package that reaches quartz sensors performances, outperforms commercial MEMS sensors, and eases integration.

The new force-rebalance accelerometer delivers an excellent one-year composite bias repeatability of 1 mg and composite scale factor repeatability of 600 ppm under severe temperature and vibration. These conditions are common in industrial, land, railway, naval and construction applications. Its characteristics enable significant reduction in size, weight and cost of materials for industrial motion control units, Inertial Measurement Units (IMU) and Inertial Navigation Systems (INS).

Tronics New High Performance Accelerometer

AXO315 is a ±14 g range, in-plane linear accelerometer. It has been designed and developed to provide high precision and reliability in the most challenging environments. Tronics new accelerometer achieves a 1 mg composite bias repeatability over one year at temperatures ranging from -55 °C to +105 °C. It achieves also 4 g vibrations with an outstanding vibration rejection.

Performance is augmented by its superior Allan variance characteristics, with an excellent bias instability of 4 µg. It also has a velocity random walk of 0.006 m/s/√h. And very low noise of 15 μg/√Hz, thus enabling high resolution and low error.

Tronic’s New Axo315 Accelerometer Performances

The new AXO315’s performance is equivalent to the incumbent analog quartz accelerometers and mechanical inclinometers. Nevertheless, but at a fraction of their size, weight, and price, while remaining free from dual-use export control according to Annex 1 of Council Regulation (EC) No 428/2009. AXO315 exhibits higher performance levels than any current commercially available MEMS sensors components. Moreover, it delivers an 80% gain in temperature stability compared to Tronics’ previous accelerometer generation AXO®215.

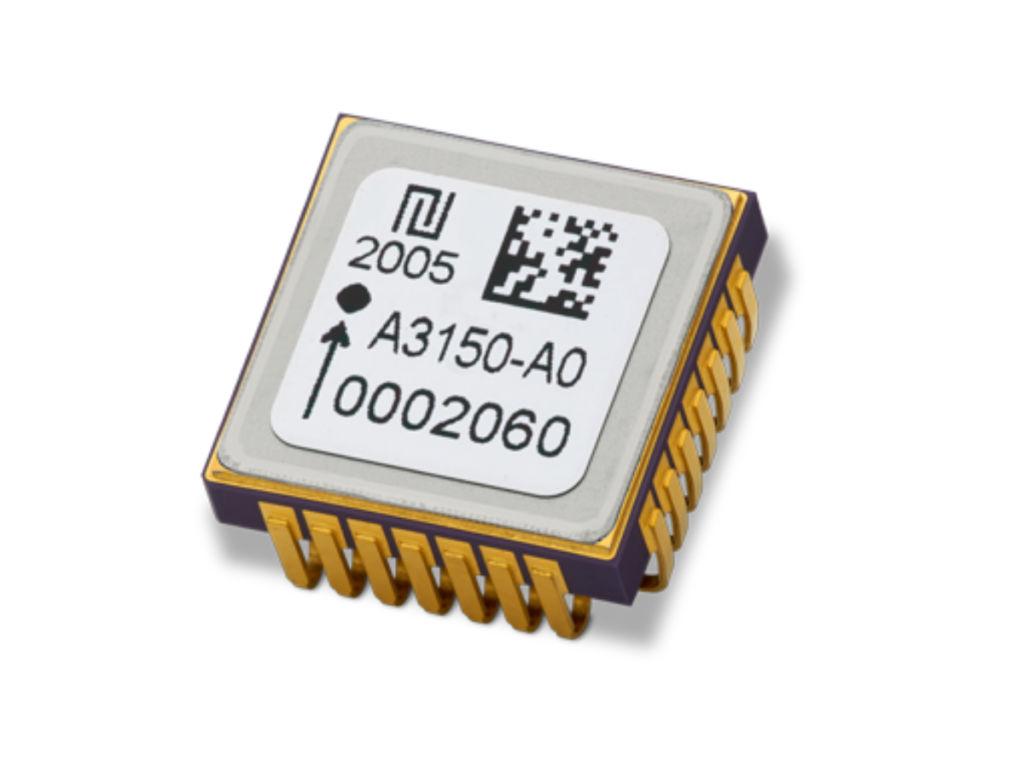

The new accelerometer complements the existing lineup of Tronics high performance GYPRO® digital gyros for high-performance IMUs and INS. It comes in a lightweight 1.4 g hermetic SMD J-lead ceramic package (12 x 12 x 5 mm), enabling low-cost assembly and reliability on PCB, even in fast-changing temperature conditions.

AXO315, Robust and Ideal for Stability in Demanding Environments

With its superior performance and robustness, Tronic’s new AXO315 Accelerometer is an ideal sensor for applications requiring high accuracy and stability in demanding environments, such as servo inclinometers and dynamic inclinometers in industrial motion control units, IMUs and INS for GNSS-aided positioning, and navigation of manned and unmanned ground vehicles and trains.

The New Axo315 High Performance Accelerometer, Made in Grenoble

The AXO315 accelerometers are manufactured, tested and calibrated at Tronics Microsystems’ facility in Grenoble, France. Pre-production and customer sampling have begun. Evaluation of the sensors can also be made through an Arduino-based evaluation kit that is specifically designed to provide developers with improved testing functionalities such as output reading and recording, recalibration and digital self-tests.

Full production of the sensors and availability through its network of distributors are scheduled for summer 2021.

For more information please see our AXO High Performance MEMS Accelerometers page.

This article was originally published by Tronics Microsystems.