BMT Drive Solutions: An Important Step in Gear Localization

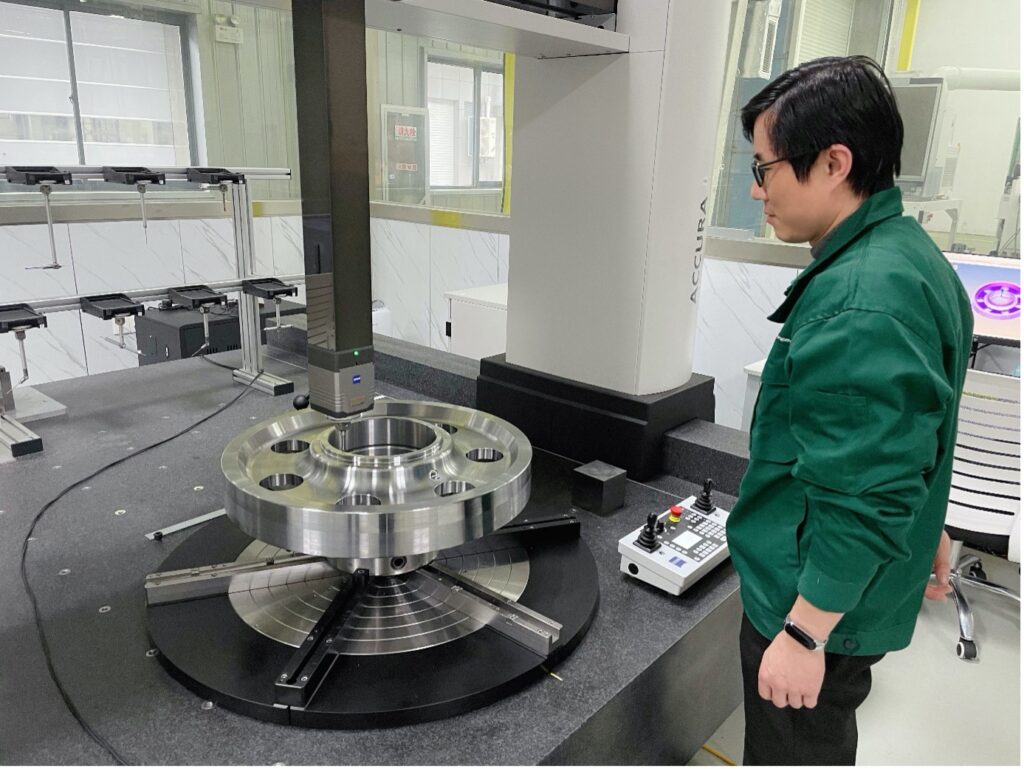

At BMT Drive Solutions, we have been moving forward and have been exploring how to provide our customers with expected products and services. Our colleagues in China have been doing this, and they have taken an important step for the domestic production of gears in the Chinese factory. Now, our Chinese colleagues can proudly announce that 16 sets of SFR gears and 37 sets of Kore gears have been successfully manufactured and delivered to IGW Suzhou on March 02nd 2021. This marks our Chinese factory’s full capability to produce high-precision railway gears locally. Through the celebration activities, our grand blueprint just started.

China’s railway market has been developing for more than ten years.

The Challenge

At the beginning of 2020, we made a full plan and prepared for the localization of the railway gear, but the epidemic disturbed all this. Indeed, our Belgian colleagues and the engineers of the European machines could not come to support on site, which is a big challenge in trial running of our production line. We overcame all these difficulties by using remote technical support technology.

Another technical issue which perturbed us for long time is grinding burns. In order to solve that problem, we have come up with up to 13 kinds of solutions. In that process, our team faced many challenges, but we gathered experiences and arrived at more optimal solutions. Thanks to their efforts and dedication, no grinding burn issues have occurred in our final delivered products. Again, many thanks go out to our Belgium colleagues and the Chinese team.

Business Perspective

So far, the production of railway gears is mainly completed by IGW in Romania, and they deliver up to several thousand sets of gears to the Chinese market each year. Now our Chinese colleagues can also produce and provide high-precision gears. At the same time, we can better meet our customers’ expectations for shorter lead times.

China’s railway market has been developing for more than ten years, consolidating its position as the world’s largest railway market. And it will maintain high-speed growth in the future, which means a huge demand for railway gearboxes. As the key components gear manufacturer for the gearbox, we also benefit from this.

At present, we have received orders of 7 projects, a total volume of more than 2,000 sets of gears and the new orders are still coming. Recently, we received orders from SZ16 and G3E projects. We will provide 515 sets of one-stage spiral gears for Shenzhen Metro companies as well as 84 sets of two-stage screw gears for Guangzhou Metro companies. Our Chinese factory’s colleagues have quickly launched the trial preparation of these two projects, confidently meeting new challenges!

This article was originally published by BMT Drive Solutions.