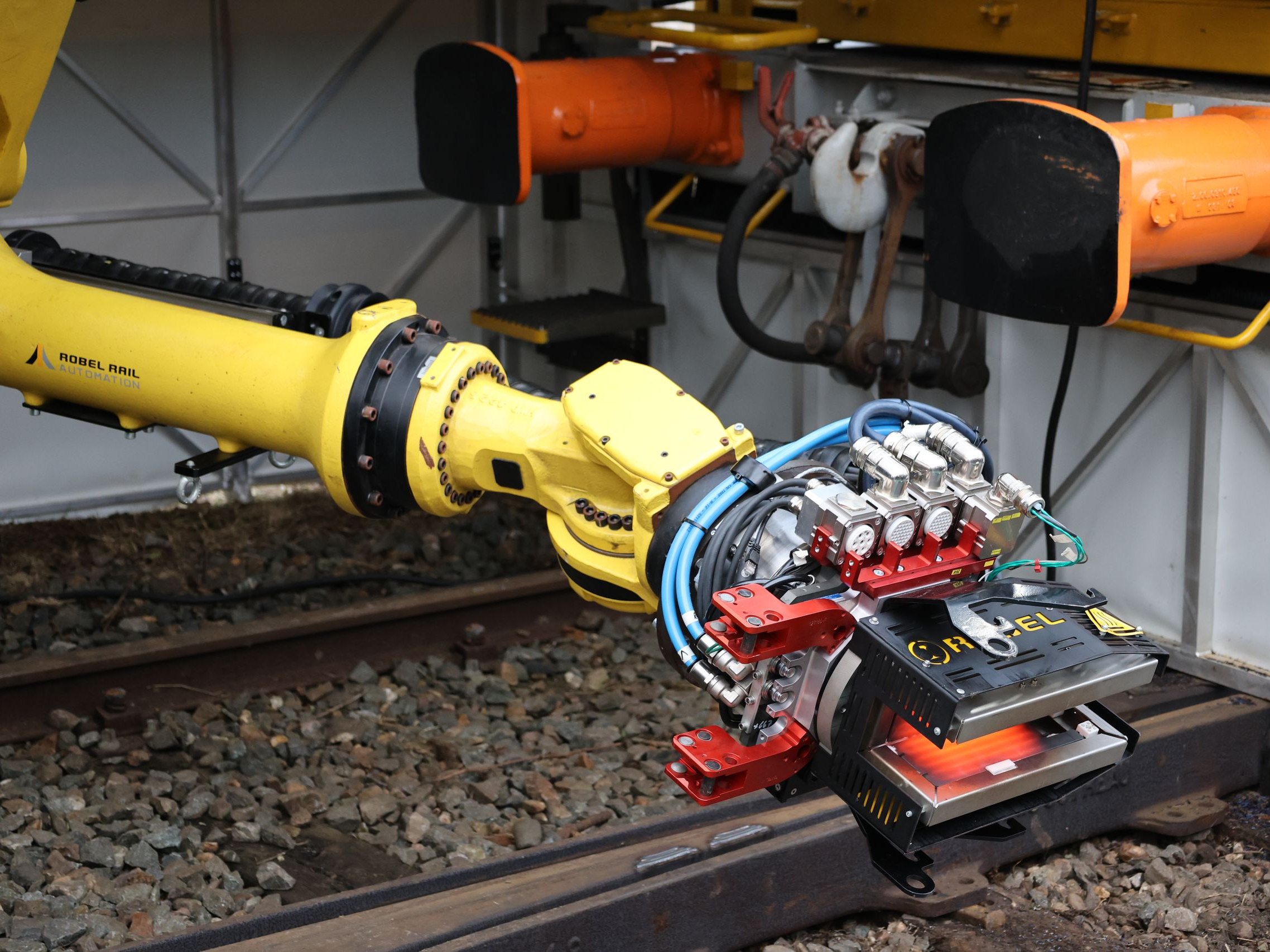

Following the success of the MINIMA and GWS tamping machines, Robel is introducing an advanced version of the lightweight agile mini tamper, which bridges the gap between manual track geometry repairs and strategic tamping with larger machines.

The machine comes in three models:

- Single plain line fixed tamper head

- Dual plain line fixed tamper head

- Single adjustable tamping head for switch & crossing

With its compact construction the ROMITAMP 2.0 complements the larger tamping fleet by delivering a flexible, low-cost and fast repair solution for shorter maintenance and renewal sites.

Proven Plasser & Theurer Tamping Technology

All models feature the proven technology with the Plasser & Theurer asynchronous 35 Hz head for high-performance tamping. With its compact design, the machine complements the larger tampers by delivering a fast, flexible and low-cost repair solution for maintenance repairs and shorter relays while still delivering the big machine performance to give confidence for line speed hand back.

Fast, Safe and Easy On/Off Tracking

The machine can be easily transported by road to an access point and then mounted on to the track safely and quickly. There are two options for on and off tracking:

- Either by using special additional road wheels mounted on the vehicle axles together with an underframe turntable (only possible on the fixed tamper head model). Machine turning on canted track can also be accommodated with the additional option of four lifting jacks which level the machine before turning.

- Or with robust all-terrain wheels mounted on the front and rear of the tamper. The all-terrain wheels feature an internal brake system which allows offloading from the transport vehicle using a ramp and also allows turning within its own length.

Directional Travel and Working Mode

When on rails, the tamper can be driven both forwards and backwards at 25km/h to and from the worksite. The operator chair rotates 180 degrees to allow easy sighting in both directions. Alternatively, the fixed frame model can be turned using the turntable.

Fast Track Repair with Lift and Lining Capability

The tamper can operate at an impressive 360 sleepers per hour and has the option for bi-directional working to allow tamping of both the run on and off at fix structure without the need to turn the machine.

With the option of an integrated lifting and lining device, together with a super elevation measuring unit, the machine offers a complete solution with just one operator. This means considerable savings when compared to a road-rail vehicle with a tamping head which requires several employees to manually jack and slew the track.

As part of future improvements of the ROMITAMP, Robel will also be looking to develop a track recording system which will monitor track parameters and allow feedback to engineers on the track geometry achieved.

Comfortable and Ergonomic Cab Design

The ROMITAMP comes with the option of a fully enclosed cab with heater and air-conditioning. The enclosed cab also offers protection for the operator from ballast dust generated during the tamping process.

In working mode, the operator has an excellent elevated sighting position for clear visibility of the tamping process. A laser beam target is also available to assist the operator in positioning the tamping tines over the sleeper. The operator seat has all controls integrated in the arm rests and is fully adjusted to allow easy control of foot pedals. Monitors supply the operator with feedback on lift, line and cross level adjustments applied to the track.

In the cab there is also a ‘buddy seat’ to allow transport of one extra person. This seated person can also act as the pilot to aid sighting when the tamper is operated in the reverse direction.

A Machine for All Track Configurations

To allow greater operational flexibility, the machine’s wheelset and lift & lining device can be configured to accommodate a range of track gauges from 900 to 1676mm. Adjustments can also be made to allow the tamping of a range of sleeper and bearer spacings.

The fixed tamping head machines are designed for plain line tamping only. The adjustable tamping head machine features the tines which can be individually rotated to the horizontal allowing tamping around obstacles throughout switch and crossings layouts.

Flexible Towing Machine

Brackets can also be mounted to carry additional equipment including small Robel vertical tampers. A Rockinger coupler allows the attachment of a lightweight trolley or trailer for the transport of additional labour, plant and materials.

ROMITAMP 2.0 meets the challenge in repairing short maintenance and renewal sites more efficiently, faster and more safely than manual means or road-rail. Fast and agile for easy access and equipped with the high-performance consolidating Plasser & Theurer tamping head, the tamper delivers higher quality and longer lasting repairs. With just one operator, ROMITAMP increases productivity with significant cost-savings compared to the slow, hazardous labour-intensive manual lift and compaction methods.