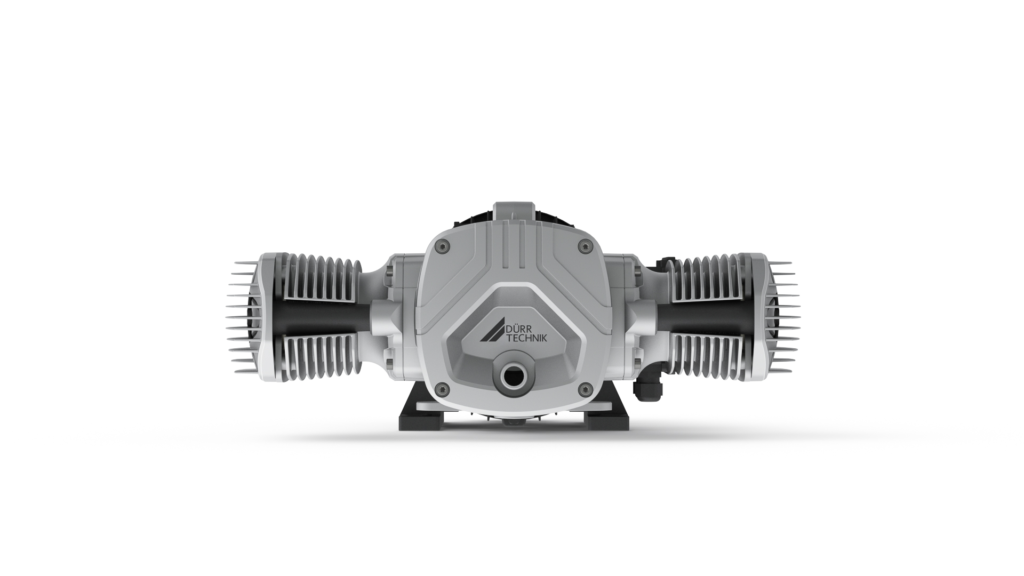

Dürr Technik is pleased to announce the upcoming launch of its next generation E-Bull.

The redesigned oil-free air compressor is fully compatible with the latest rail standards across UK and Europe, as well as many other regions around the world.

The original E-Bull model was a revolutionary compressor for the rail industry. Launched in 2020, the compact yet high power compressor was developed for use in small spaces where height was a premium. In addition, its fully sealed design made it well suited for placement underneath trains, as it would be protected from the elements – in particular dust and water.

Redesigned to Meet the Needs of Today’s Rail Customers

In response to industry feedback, the company’s engineers have redesigned and upgraded the compressor to enable its use in even smaller spaces, all while retaining – and in some cases improving – its key features.

This work was undertaken to support a variety of developments in the rail sector, where rail vehicles are designed with accessibility and sustainability in mind. These changes mean a reduction in space available due to low height floors or the addition of batteries and or fuel cells. With this in mind the E-Bull was redesigned to be even more compact, and can be built within stations with even lower heights.

Mark White-Sharman, UK Managing Director at Dürr Technik, says:An original E-Bull station would need a minimum height of 500-600mm, but the new design only requires 350-400mm.

Improved Heat Dissipation

This was made possible by enabling the rotation of the compressor’s heads and improving the high-power compressor’s heat dissipation.

White-Sharman says:We remodelled the head to ensure we can get rid of the heat generated during the compression cycle. This included redesigning the compressor heads to optimise cooling and allow the heads to be simply rotated, which makes more efficient use of the forced cooling within the compressor station enclosure.

Lower Power Consumption

White-Sharman continues:We’ve also been able to reduce the compressor’s power consumption from 3.4KW to 3.2KW – a reduction of 200 watts or approximately six percent. This not only reduces heat production, but also improves the E-Bull’s sustainability credentials.

Increased Flow Density

Although the new and improved E-Bull has a lower power consumption and lower overall height, it now produces approximately 11% more air from the same space envelop. Typically, the free air delivery has increased from 380 to 420 l/min. This increase in flow is also seen at the delivery pressure of 10 bar.

Product Manager Mouldi Warag says:These developments might not sound like much at first, but it’s actually really impressive in the context of starting with an already very compact compressor.

Customisable Solutions

The E-Bull compressor is already used on several trams and trains in Asia and Dürr Technik is currently working closely with some of Europe’s major train manufacturers on customised E-Bull solutions that meet their specific and challenging requirements.

This includes the design of new underframe and rooftop compressor packages (open frame) that can positioned within any road or rail vehicle, and can easily be slid in and out of place.

The company will also be delivering a new close frame solution where two E-Bull compressors are integrated into one station later this year in Eastern Europe. This will be followed by further units delivered to Scandinavia in 2024. This provides customers with even more flexibility, as Warag explains.

Warag says:Today customers need compact solutions and often have a lower demand for compressed air. So, we provide low height stations that have room for two E-Bull compressors and a control unit. With the addition of two compressors, we can better balance the flow demand, meaning that instead of having to use a large, power-hungry main air compressor, you can instead just start one of the E-bulls within the station and then add the second if more air is needed.

This solution also means less noise and more redundancy, plus by switching between the two units you can also better manage wear and tear.

The new model and low height stations allows our customers to be a little more creative with the control and management of their compressors.

The new stations have been designed with maintenance in mind, meaning that wear parts are easily replaceable. The E-Bull offers very low cost of ownership as the minimum of maintenance is required. As all Dürr Technik’s compressors are oil-free, they also remove the issues associated with recycling and disposal of hazardous waste at the depot.

Pre-order Your Next Gen E-bull Now!

The company is keen to hear from other rail vehicle manufacturers interested in pre-ordering an E-Bull solution ahead of the official September launch.

If you’re interested in being one of the first to take advantage of this redesigned and upgraded, compact, high-power air compressor then contact them for further information or to place an order.