Batteries are key components of train operation. When parked on the rail yards (storage, marshalling, etc.), trains’ pantographs cannot remain in contact with the catenary without significant safety risks (e.g., damage to electrical circuits that could cause a fire).

Pantographs are therefore held down when the train is not in operation. So, enabling a train to operate depends on the battery capacity to lift the pantograph, which is the only component allowing the train to leave its yard.

Monitoring batteries is then a crucial issue:

- To maintain the service quality to customers

- To optimise operations by avoiding delays and heavy re-commissioning interventions

Battery Voltage: The Key Indicator

The use case is simple and unfortunately occurs on a too regular basis: a train is parked, pantographs lowered while a control system has not been disconnected resulting in a battery drain in only a few minutes.

Consequences can be serious, with:

- The potentially permanent deterioration of the batteries requiring their replacement,

- Train service disruption

- A negative impact on the perception of the service level and quality by passengers

Real-time monitoring of the battery voltage is the key to overcome these difficulties.

Data Collection Using a Rail-Certified Connected Device

Consulted by a major European rail operator, STIMIO relied on its RAILNODE certified rail solution to help prevent these events.

RAILNODE boxes are connected directly to the locomotive batteries. They measure and monitor voltages in real time. Alerts are then raised as soon as the voltage drops below a predefined critical threshold.

Finally, these alerts enable on-call operators to intervene quickly to identify the problem and take corrective action.

In conclusion, battery voltage monitoring allows operators to proactively anticipate battery drain and greatly reduce response times.

An Integrated Solution to Anticipate Battery Deterioration

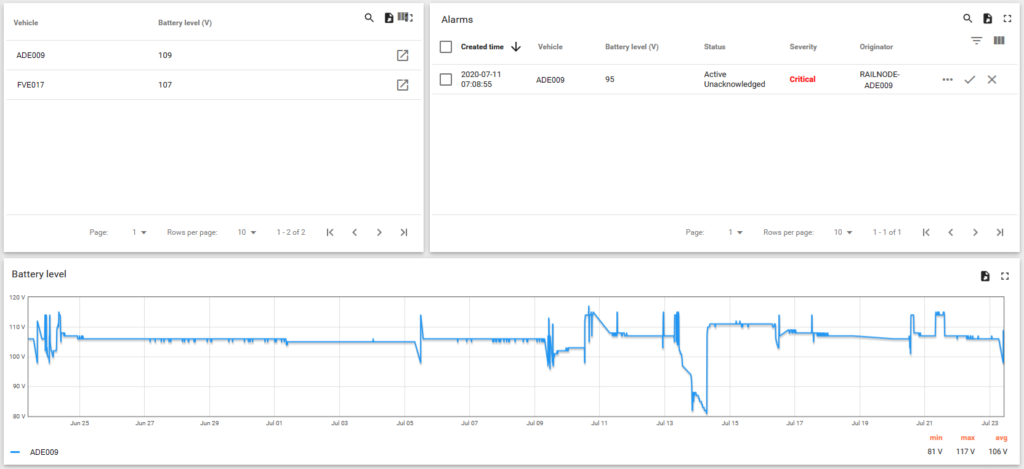

STIMIO provides an integrated turnkey solution, from sensors to cloud interface. Voltage readings are uploaded in real time to the cloud and available on a dedicated dashboard. This allows the monitoring of the voltage evolution and the reception of alerts.

The analysis of dashboard data makes it possible to anticipate battery wear and to plan maintenance operations before failure.

A Wide Range of Railway-Dedicated Connected Devices

STIMIO offers a portfolio of connected devices for the railway industry, covering a wide range of use cases to help operators face their many challenges. In addition to battery voltage monitoring, STIMIO’s solutions are designed to monitor:

- Catenary icing

- Catenary tensioning

- Rail and catenary temperatures

STIMIO’s offering also includes connected devices for data collection inside rollings stocks (doors monitoring, fluids level, etc.).

If you are an operator and face similar problems with your rolling stock (trains, metros or trams), contact us!

This article was originally published by STIMIO.