In 2016, a freight train has fallen into the Tolten River after the railway bridge collapsed. The train was carrying chemicals, putting at risk the entire environment.

Railway bridges implies the work of a reliable community as structural engineers, designers, and specialized suppliers for material and components.

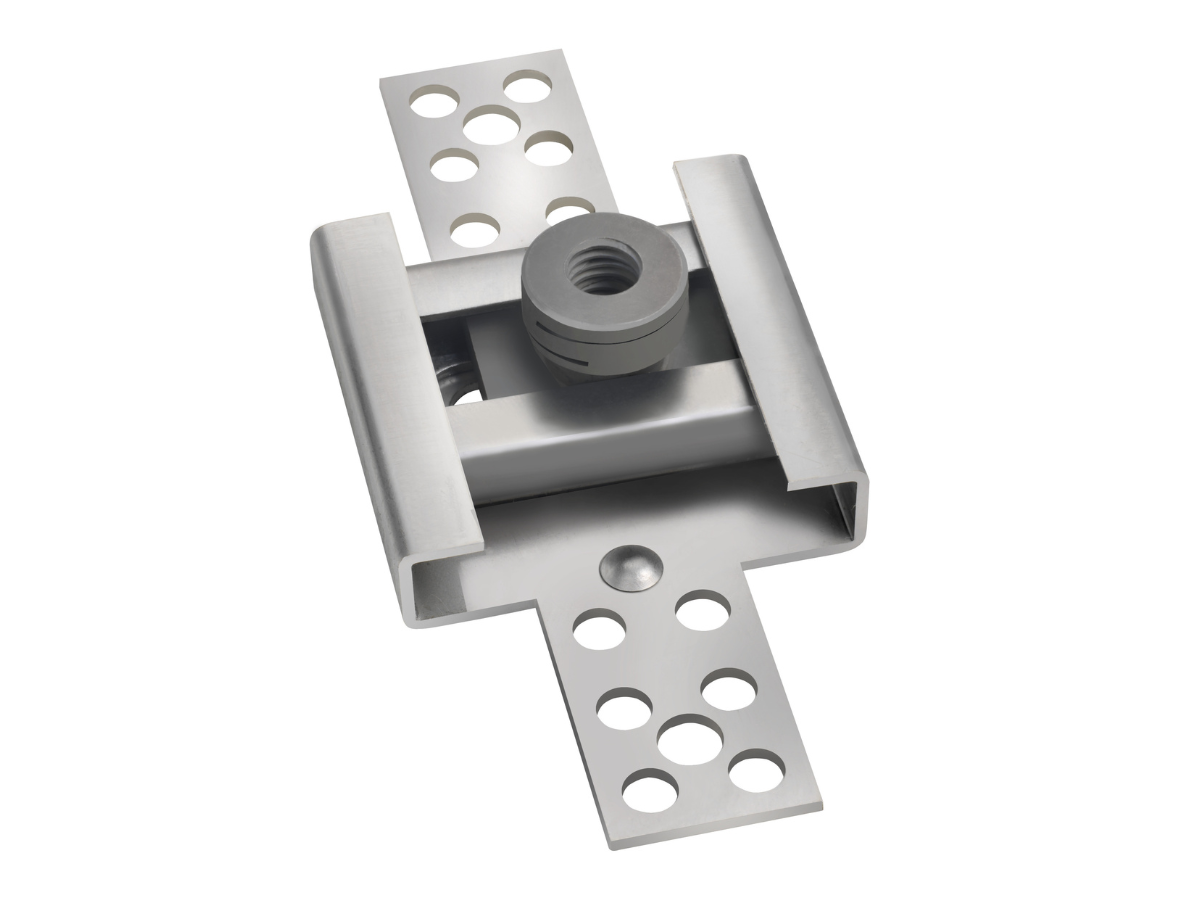

The decision of changing a fastener system can improve the whole reliability of a construction.

In this case, we were chosen because our self-locking nut would be used in a country with a hard environment (often solicited by earthquakes, fire forest, floods) and as railway bridge, the vibrations and movement could potentially loosen even untraditional nuts over time, putting again at risk the safety of this bridge.

ESL self-locking nut ensures constant tension during the 5 assemblies (ISO 2320), getting rid of chemical brake in the assembly, measuring perfectly coefficient of friction.

If you need a self-locking nut able of withstanding high loads and stresses for structural integrity and vibration damping, our ESL will guarantee resistance to variable environmental conditions and dynamic load.

In bridge construction, you can decide to weld to initially spare money (on material weight) but that means you will have to organize an amazing and special transport that will require authorizations, block roads and increase timing, but also the final cost.

The other option is to bring all the different parts of the bridge separated and assemble them together with the right fasteners, no more special operation on roads, you can pre-assemble and reuse the same self-locking nuts. All your project can go faster.

For this renovation, J. LANFRANCO & Cie used the following types of nuts:

- 10,439 ESL 5/8″ nuts in CL8 steel

- 10,436 ESL 1” 1/2″ nuts in CL8 steel

- 15,000 ESL 3/4″ nuts in CL8 steel

- 1,713 ESL 5/8″ nuts CL8 steel

Today, the success of the restoration is demonstrated by the satisfaction of the engineers, as the bridge has been reassembled in accordance with the projections made. Its solidity was successfully demonstrated in 2020.

Over the past five decades, our company has established itself as a major player in the field of safe fasteners.

Our commitment to innovation and quality has enabled us to provide reliable solutions, such as our self-locking nuts, for such important renovation projects as the Tolten Bridge.

This article was originally published by J. Lanfranco & Cie.