Safety Nuts and Fixing Systems for Rail Applications

Locknut Specialist for Critical Bolted Joints

Present on the market for over 40 years, ESL and ERM have made J. LANFRANCO safety nuts the most recommended safety fixing system for critical assemblies and fastening systems. No matter the conditions, our self-locking nuts have a real ability to withstand extreme vibrations.

Regardless of your environment – cold, hot, humid or corrosive – our nuts will allow you to add value: longer life-cycles, better production times, lower costs and reduced maintenance times.

Our company is ISO 9001-2015 certified and does everything required on a daily basis to improve quality management.

Our plant is dedicated to manufacturing. It has a dozen robotic transfer units with a manufacturing capability that enables the production of small and large batches, ranging in diameter from M2 to M68. We also have digital control machines that allow us to produce bespoke parts according to plans and special standards.

With a high storage capacity, most of our pieces are available in all diameters, materials and stock protections. In addition, our extremely short manufacturing cycle allows us to respond quickly to urgent requests and specific orders.

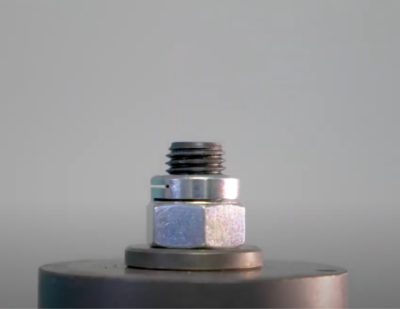

Self-Locking Nuts

J. LANFRANCO self-locking nuts are used on passenger trains, freight equipment, track works, in electrification, on metro, trams and buses.

Whether it is for high-speed trains, metros or freight cars, there is always a common objective: that J. LANFRANCO’s nuts are functional and ensure safety. When public safety is at stake, don’t risk it with sub-par fasteners.

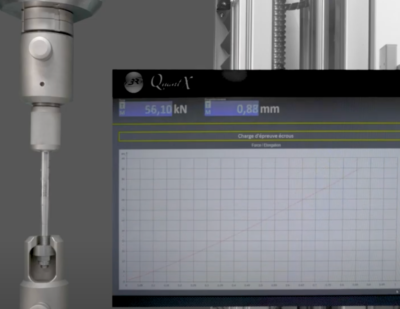

J. LANFRANCO’s self-locking nuts are tested systematically in different conditions and they withstand corrosive and extreme conditions. Our nuts have gone through every rigorous quality control:

- Resistance to shock and vibrations

- Very high thermal resistance

- Fully traceable

- Easy to assemble and disassemble

- No seizing or thread damage

- Resistance to corrosion

- ISO-certified

- One-piece all-metal design

- Compatible with any standard tools and bolts

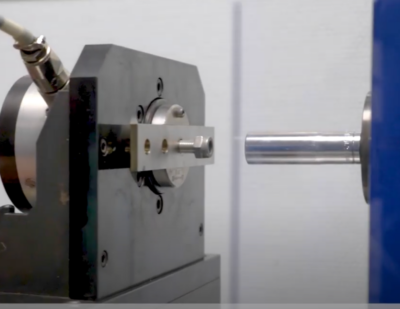

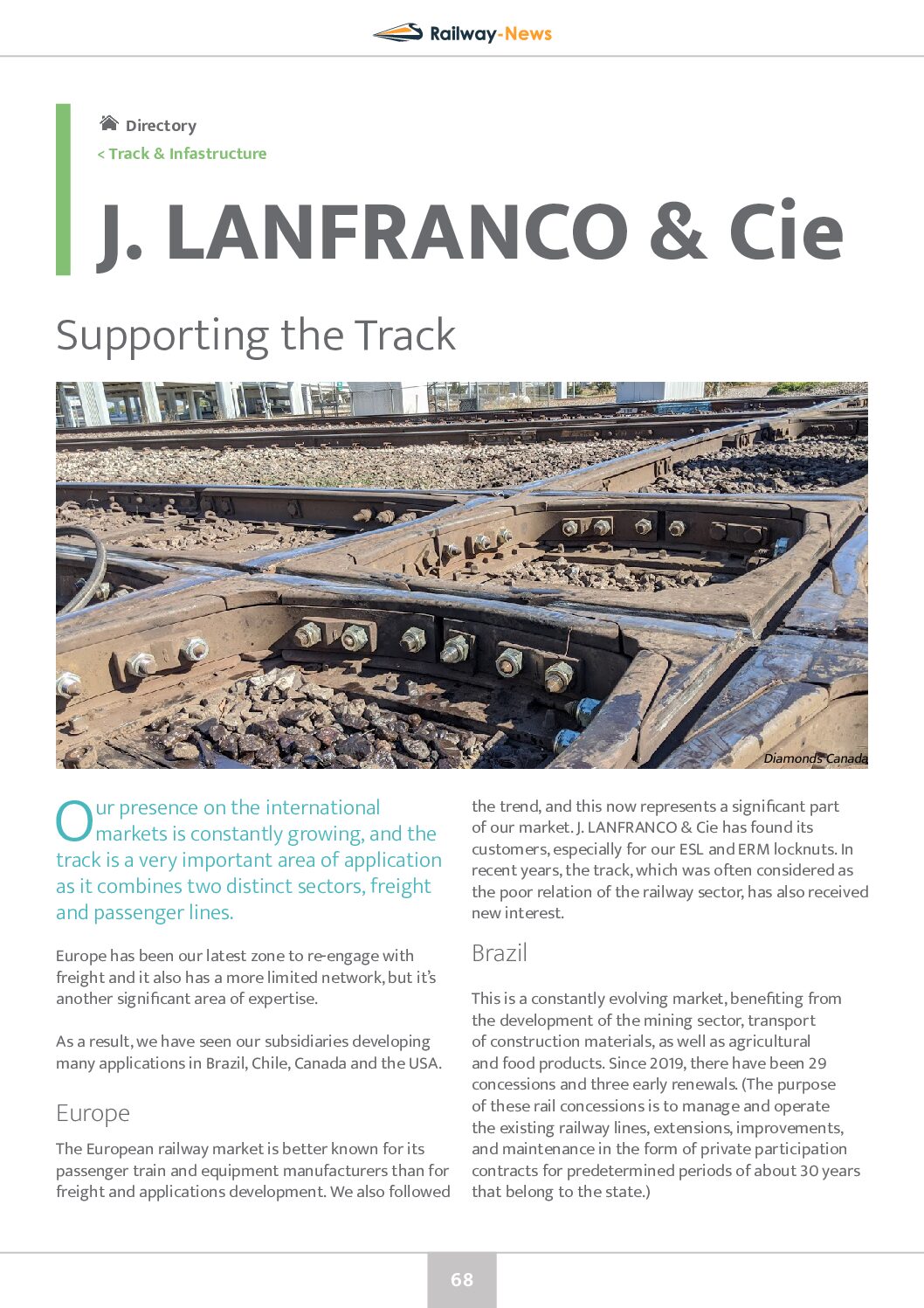

Railway Track Infrastructure

Electrical connections with an insert for earth bonding. Only two parts are needed. One ERM nut and one insert to replace your old assemblies (nut + washer + insert) that were usually followed by loosening with a loss of the electrical connection. Ours is an ideal assembly, a fast assembly (one reusable nut), without loosening, a guarantee of constant electrical contact to avoid all incidents related to loss of power.

Railway Freight and Passengers

Tracks require maintenance, both for freight and passengers, and some points are more critical than others, such as switches and joint bars. They are subject to many vibrations, shocks and forces.

Because budgets are often more limited here than for rolling stock, there is not the staff to service miles of track and be able to service assemblies that are often mistreated by their climate and geography.

The tools available don’t always make maintenance easier, but whether it’s a torque wrench or an impact wrench, the THU can take anything. There is no risk of loosening, and the THU will be your best ally and best guarantee for the safety of track devices.

Railway Rolling Stock

Regardless of the environment, extreme temperatures and corrosion conditions, both ESL nuts provide better resistance to vibration and shock over time.

The Double Slotted Nut ESL can be reused up to 5 times (standard). It guarantees safe and fast assembly with no loosening and it is easy to remove. It features maximum reliability against vibration, temperature and corrosion; it is reusable, it doesn’t seize and it is easy to assemble and disassemble.

Railway Catenary

The ERM nut reduces the number of pieces of your assembly (nut, nut against nut, drilling, pin). The washer ensures a constant and continued contact with the bearing surface compensating the defects of foundry parts of the catenary, leaving no place for loosening and enabling a perfect electrical contact.