Henkel – Assembly, Maintenance and Cleaning Solutions for Rail

Henkel, the leading solutions provider for adhesives, sealants and surface treatment solutions worldwide, offers much more than quality adhesives for the railway industry. We support train specialists from conception and design to maintenance and repair.

Henkel provides an extensive range of assembly, maintenance and cleaning solutions for a large scale of railway applications.

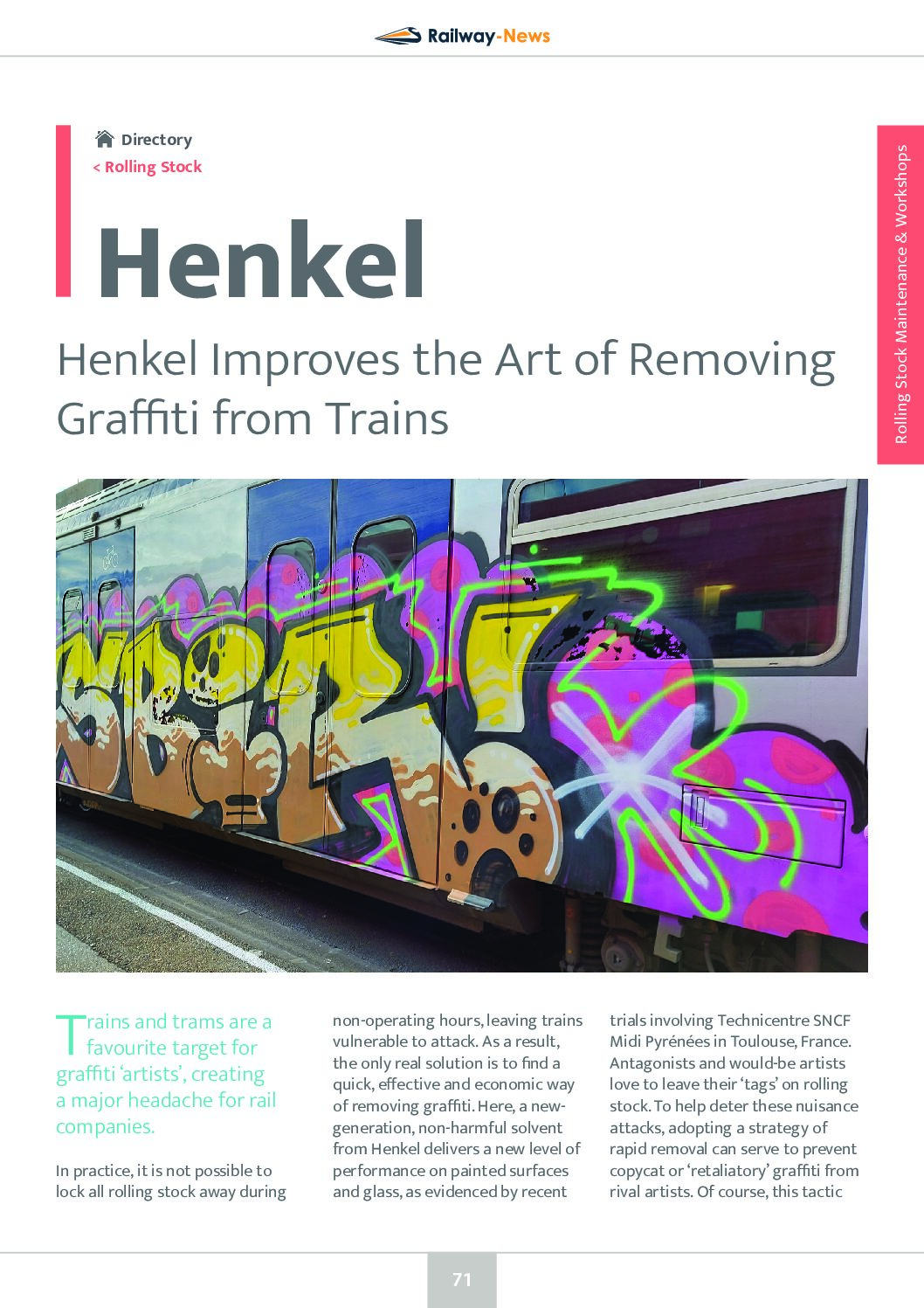

Cleaning Solutions for Rail

Henkel commits to set high expertise concerning cleaning, corrosion protection, paint adhesion and the respect of the health and safety. Its extensive product range include solutions for removing dirt, grease, machine oil, paint, rust and other types of soils.

Some examples of cleaning and surface protection applications:

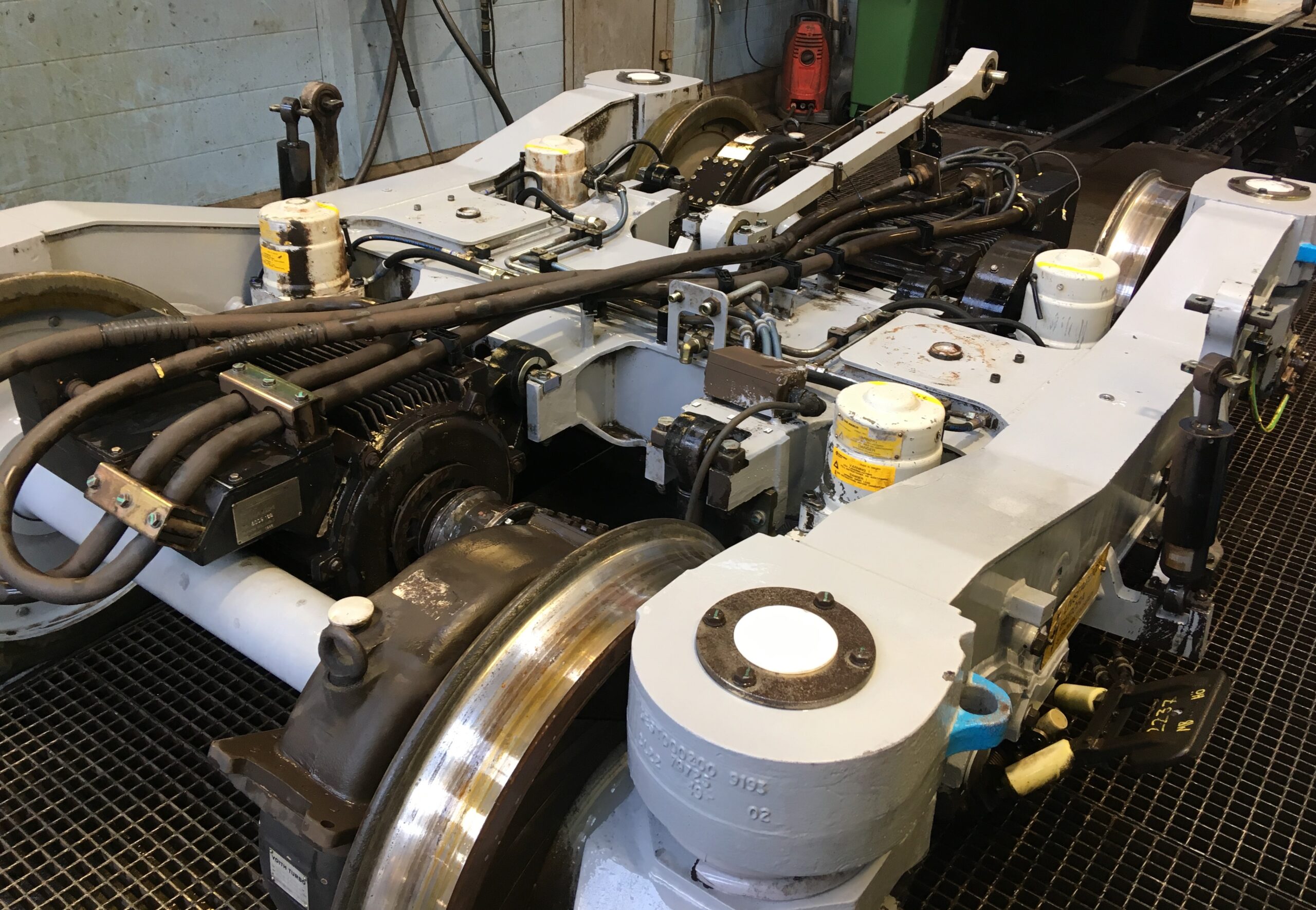

- Bogie cleaning

- Corrosion protection

- Graffiti removal

- Exterior cleaning: windows, body, underbody

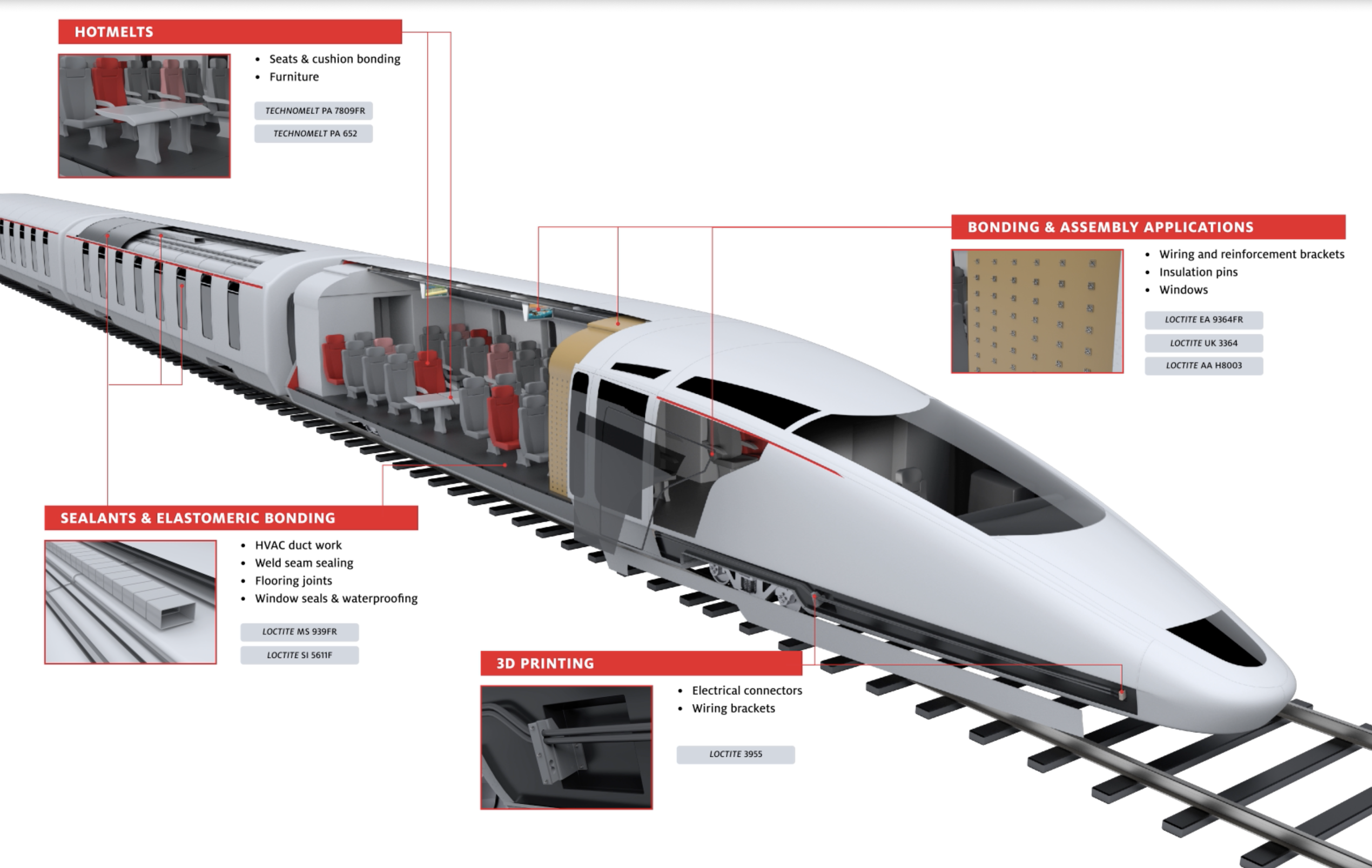

Assembly Solutions for Rail

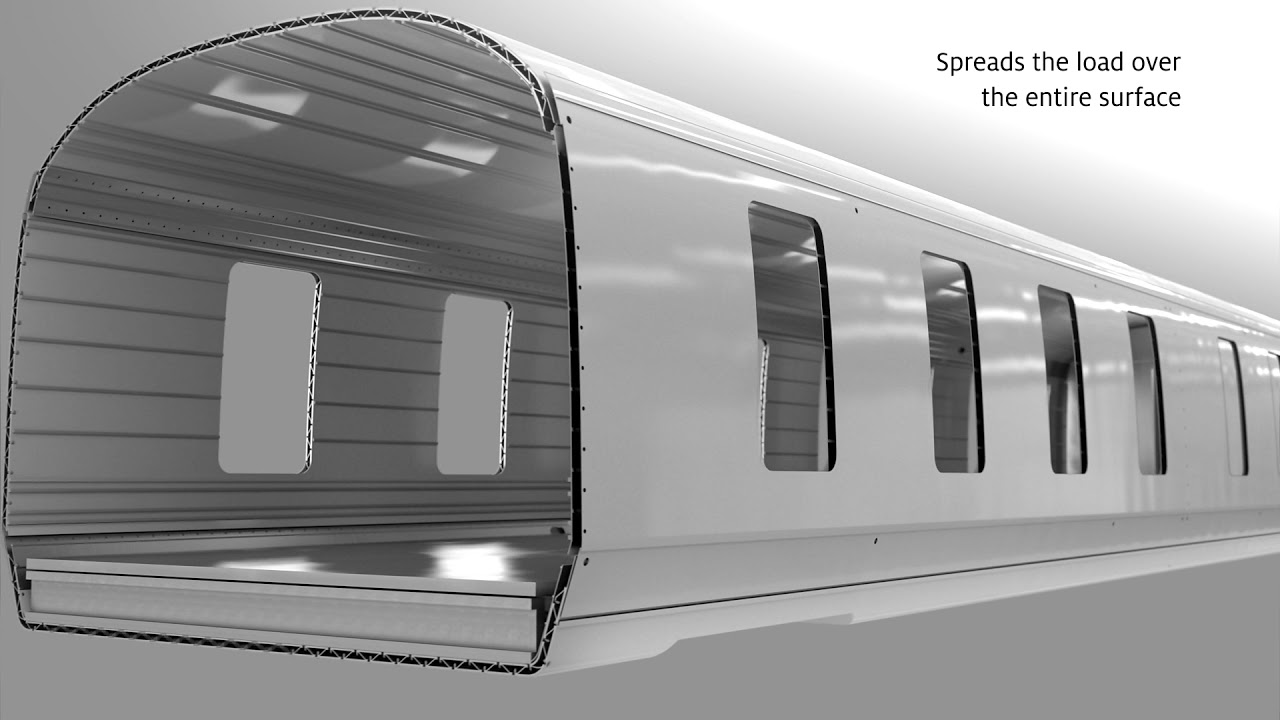

Henkel is a reference concerning railway assembly applications. From structural bonding to seam sealing and window glazing, we provide a complete range of technologies that allow you to reduce or replace traditional mechanical fastening and sealing methods in a large scale of assembly applications.

Some examples of assembly applications:

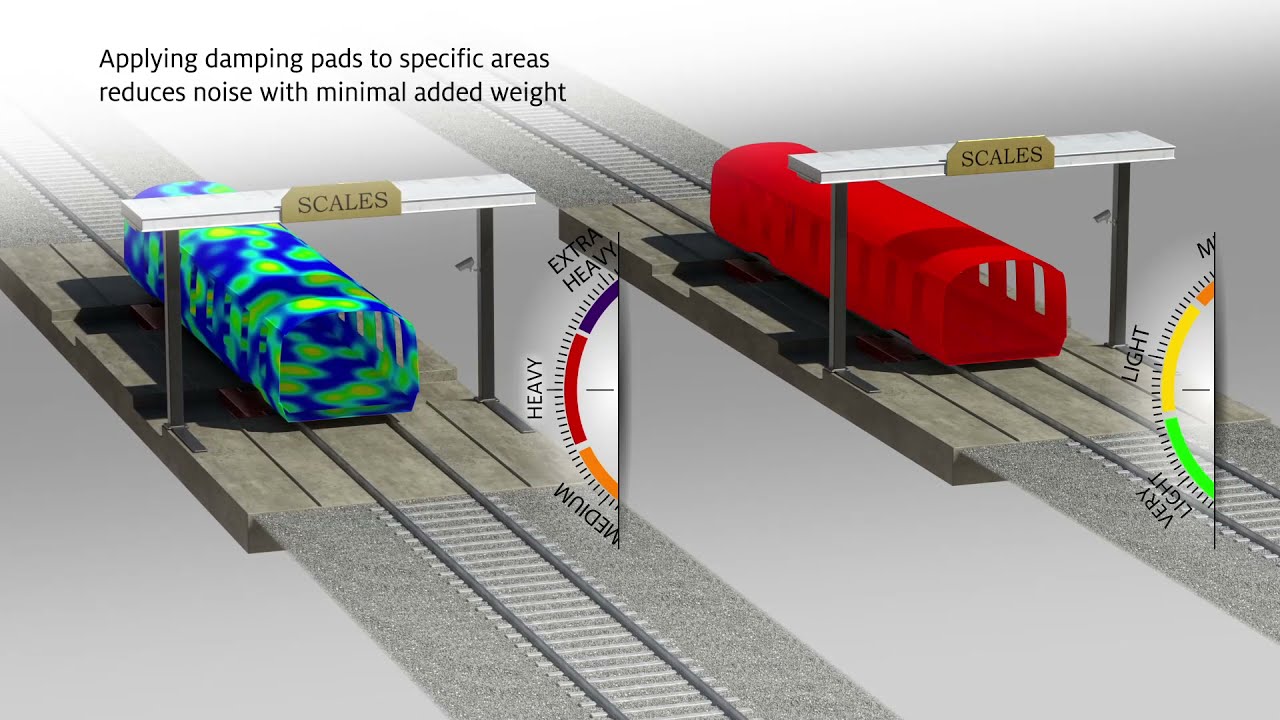

- Noise vibration and archness

- Elastomeric bonding & sealing

- Door panels bonding

- Train windscreen sealing

- Floor bonding

- Compressor sealing

- Sound reduction system optimization

- 3D printing

- Electrical components bonding & sealing

Download the Sealing Applications for Rail technical paper here.

Maintenance Solutions for Rail

A regular and reliable maintenance is essential for the successful running of railways. It helps to increase productivity, reduce costs and improve the safety and reliability, for the benefit of passengers. In that area, Henkel provides various solutions, from threadlocking of mechanical parts, to anti-slippery solutions on floors and platforms. Henkel can support on rolling stock as well as on infrastructures.

Some maintenance applications:

- Threadlocking bolts of electrical switch

- Retaining of bearing

- Anti-slip coating

- Insect removal

- Compressor sealing

- Mounting wheel onto shaft

Optimize your manufacturing processes and drive down costs, reduce weight, increase durability and enhance the reliability of your equipment. We’re continually developing innovations to help you succeed in the future.